Dyeing equipment for bamboo charcoal fiber composite cloth

A dyeing equipment, bamboo charcoal fiber technology, applied in the field of bamboo charcoal fiber, can solve the problems of dyeing to the newly inserted composite cloth and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

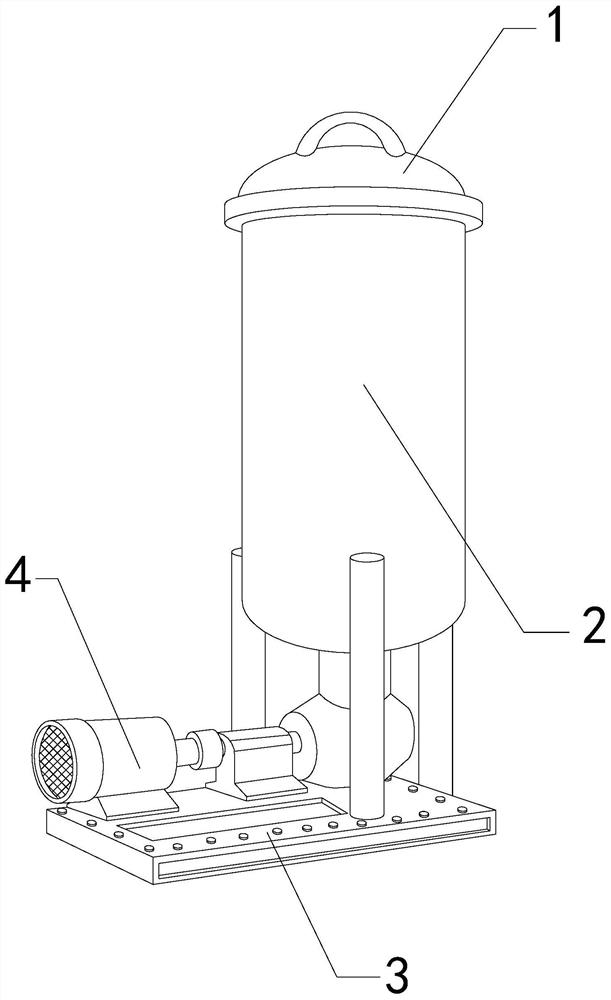

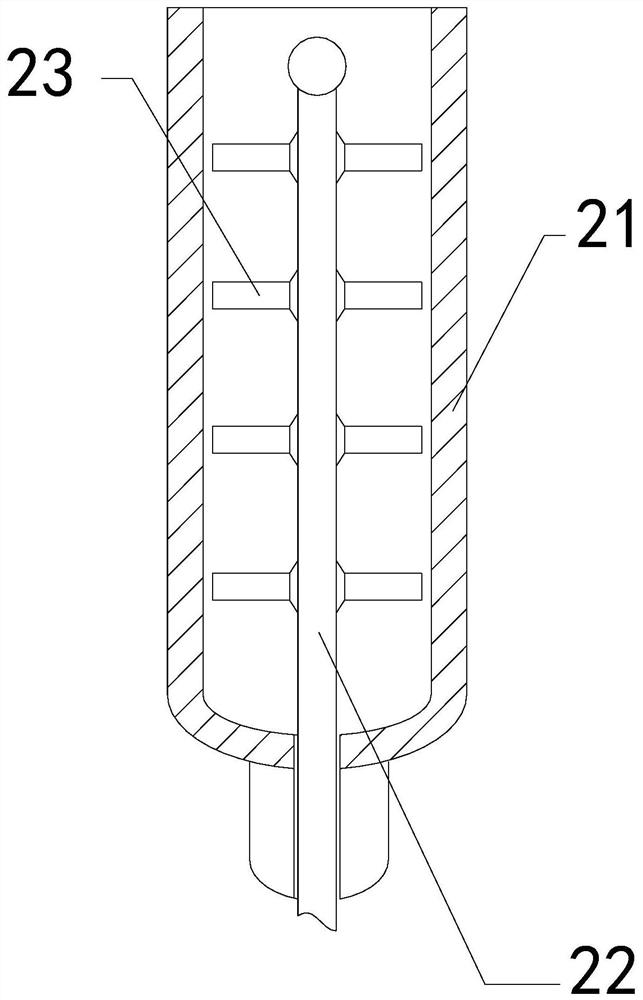

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The invention provides a kind of dyeing equipment of bamboo charcoal fiber composite cloth, and its structure comprises top cover 1, dyeing tube 2, base 3, driver 4, and described top cover 1 is installed on the top position of dyeing tube 2, and described driver 4 is connected with dyeing tube 2. The bottom of the cylinder 2 is connected, and the bottom of the dyeing cylinder 2 is welded to the upper surface of the base 3; the dyeing cylinder 2 includes an outer solid frame 21, a middle rod 22, and a blade 23, and the middle rod 22 runs through the The inner position of the outer solid frame 21 , the blade 23 is welded to the outer surface position of the intermediate rod 22 .

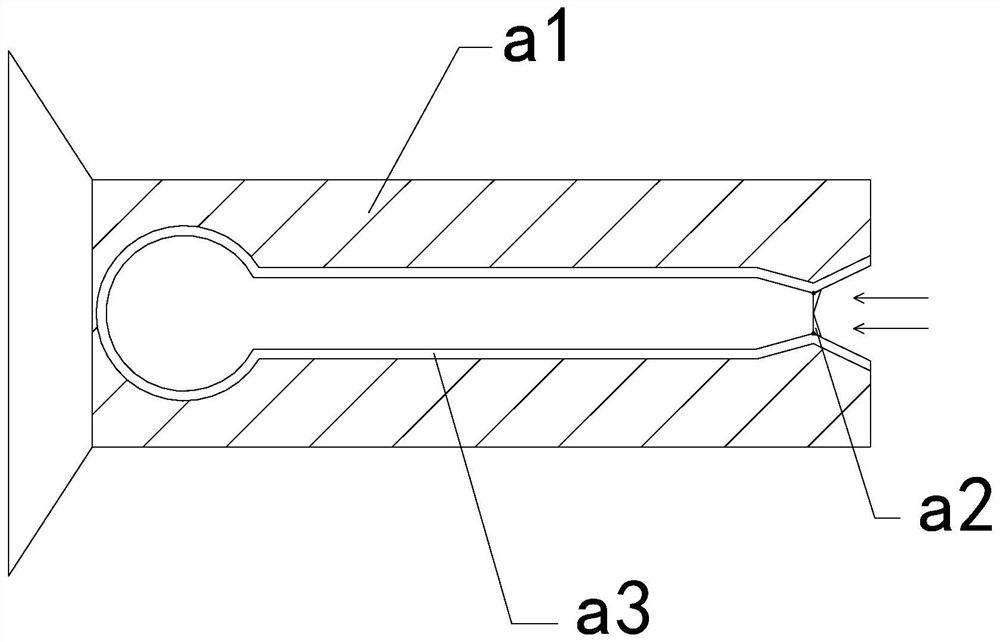

[0030] Wherein, the blade 23 includes an outer board a1, a reverse piece a2, and a built-in cavity a3, the reverse piece a2 is movably engaged with the inner side of the built-in cavity a3, and the built-in cavity a3 is embedded in the i...

Embodiment 2

[0036] For example Figure 6 -example Figure 8 Shown:

[0037] Wherein, the middle rod 22 includes an outer expansion plate c1, a middle rod c2, and an elastic ring c3. The outer expansion plate c1 is slidably matched with the inside of the middle rod c2, and the elastic ring c3 is fixed on the two outer expansion plates. Between the inner side of the board c1, there are three outer expansion boards c1, and two of them are evenly distributed in parallel inside the center rod c2, and the throwing force generated by the rotation of the mechanism can make the outer expansion board c1 Under the cooperation of the elastic ring c3, it slides outwards along the center rod c2, so that the outer expansion plate c1 can expand the bamboo charcoal fiber wound on the outside of the center rod c2.

[0038] Wherein, the outer expansion plate c1 includes a contact surface c11, a cutter c12, an impact piece c13, and a rear connection plate c14, the left side of the contact surface c11 is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com