Oil stain cleaning agent processing equipment for environmental protection equipment

A technology of environmental protection equipment and processing equipment, applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of difficulty in removing powdery raw materials, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

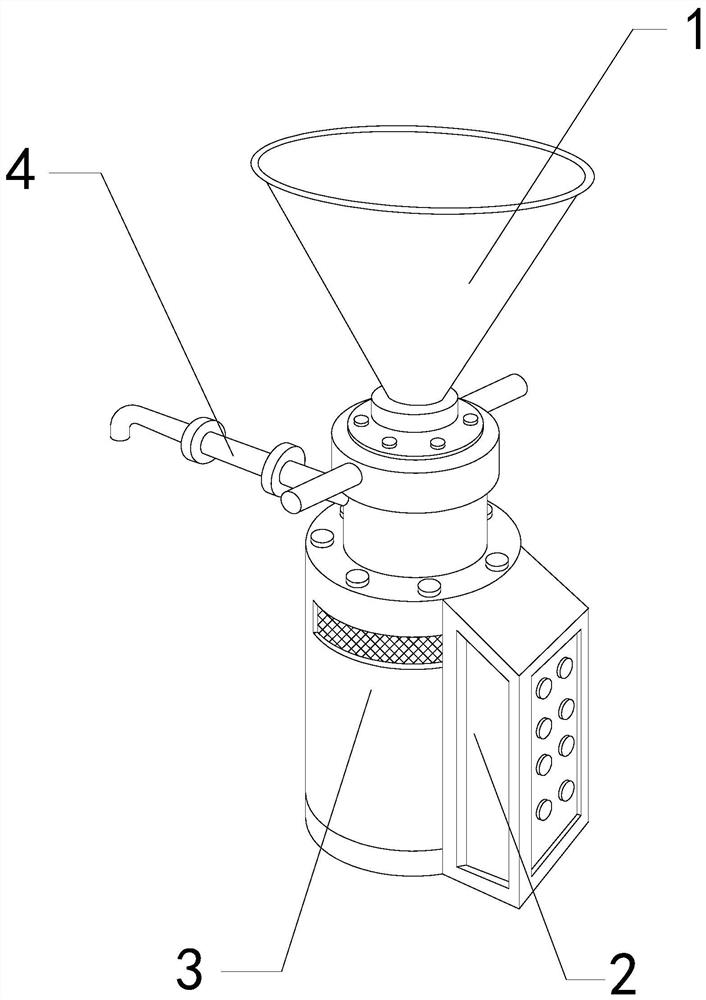

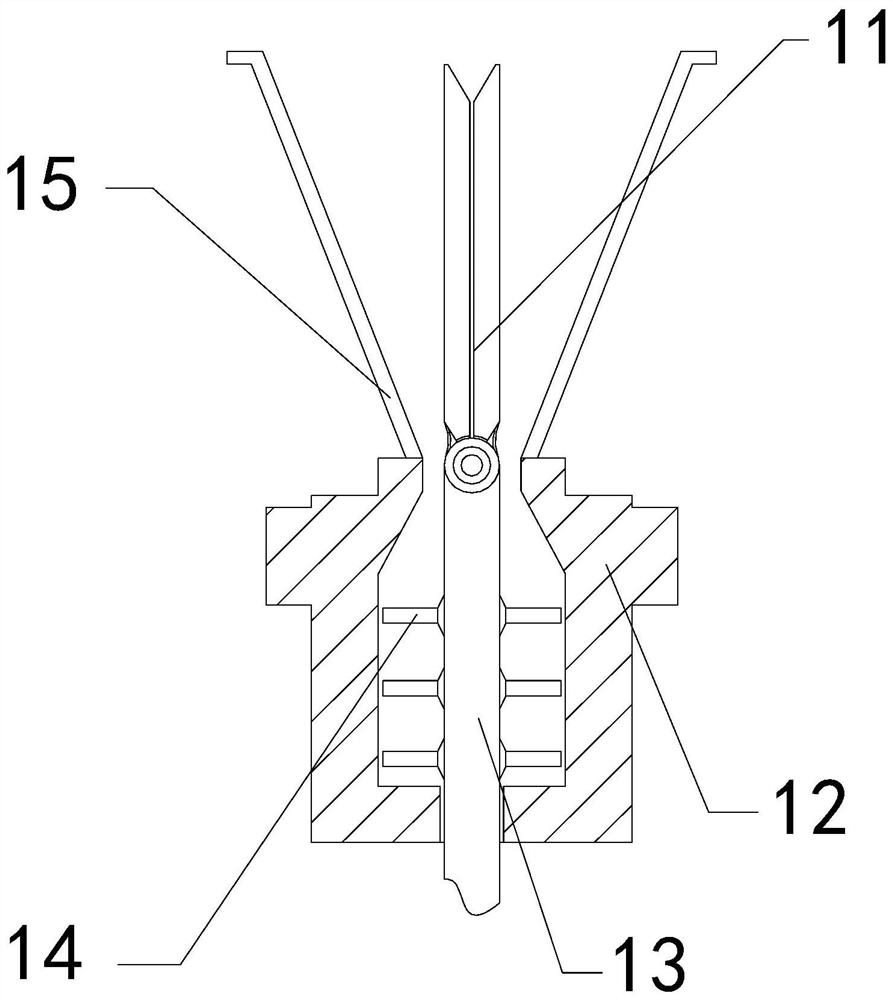

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The invention provides a kind of processing equipment for oil cleaning agent for environmental protection equipment, its structure includes a feed hopper 1, a control electric box 2, a drive base 3, and an outer discharge pipe 4, the rear end of the control electric box 2 and the drive base 3 The surfaces are attached together, the outer discharge pipe 4 is connected to the rear end flange of the drive base 3, and the feed hopper 1 is embedded in the upper end of the drive base 3; the feed hopper 1 includes an outer swing plate 11, Bottom frame 12, rotating shaft 13, blades 14, frame body 15, the outer swing plate 11 is hinged to the top of the rotating shaft 13, the rotating shaft 13 runs through the inner position of the bottom frame 12, and the blades 14 are fixed on the top of the rotating shaft 13 The outer surface position, the frame body 15 is welded to the upper end position of the bottom frame 12 .

[0...

Embodiment 2

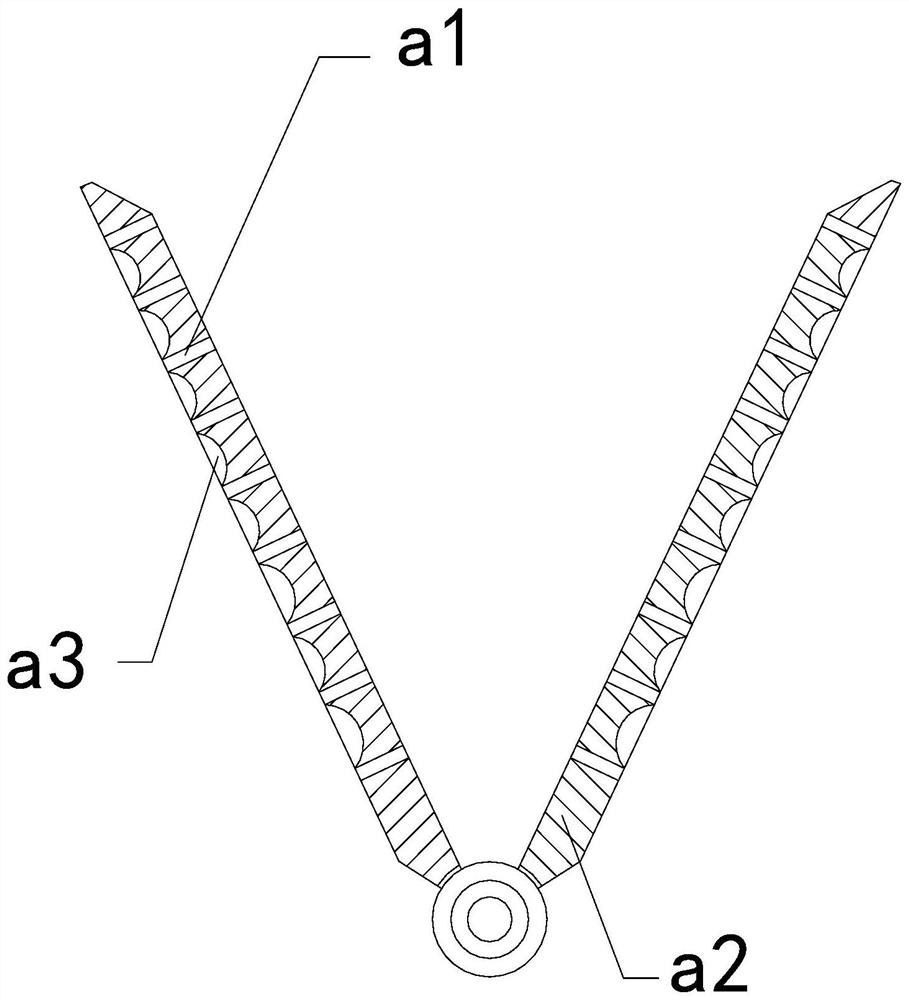

[0036] For example Figure 6 -example Figure 9 Shown:

[0037]Wherein, the contact reduction groove a3 includes a rear plate c1, a middle slide plate c2, a pullback ring c3, and an outer vibration block c4, the middle slide plate c2 is slidingly matched with the inside of the rear plate c1, and the pullback ring c3 is installed Between the inner side of the rear plate c1 and the rear end of the external vibration block c4, the rear end surface of the external vibration block c4 is connected to the front end of the middle slide plate c2, and the vibration generated by the mechanism swinging to the middle can make the outer The vibration block c4 slides outward along the rear plate c1 under the cooperation of the middle slide plate c2, so that the external vibration block c4 can generate an outward throwing force on the powder raw material attached to its surface.

[0038] Wherein, the external vibrating block c4 includes an elastic piece c41, a fixed rod c42, and an extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com