Strength detection device for steel preparation

A strength detection and steel technology, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of slipping of steel bars, loose rust layer on the surface of steel bars, errors, etc., to enhance the gripping force , to avoid slippage, to avoid the effect of rust debris that is difficult to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

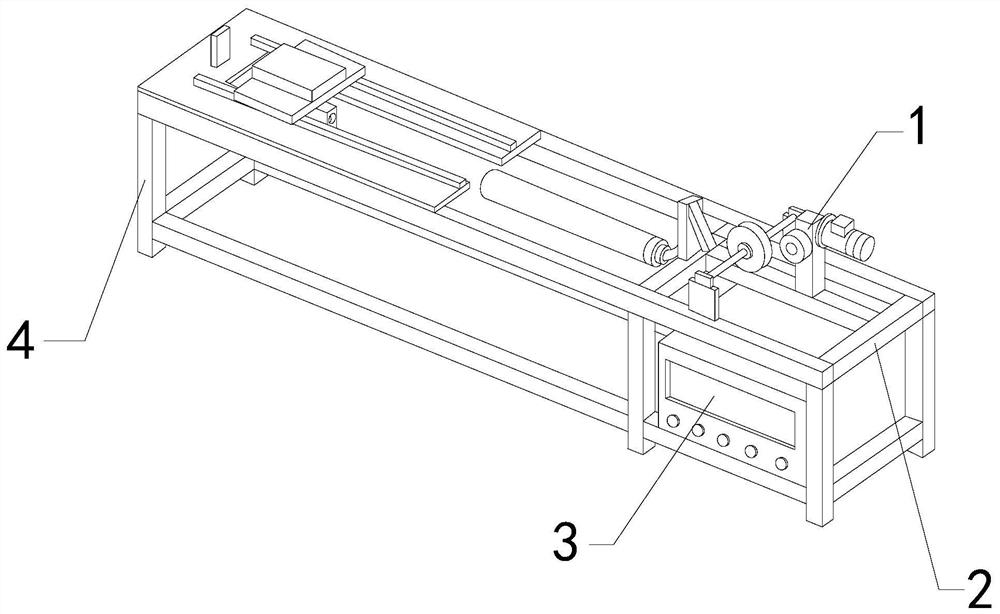

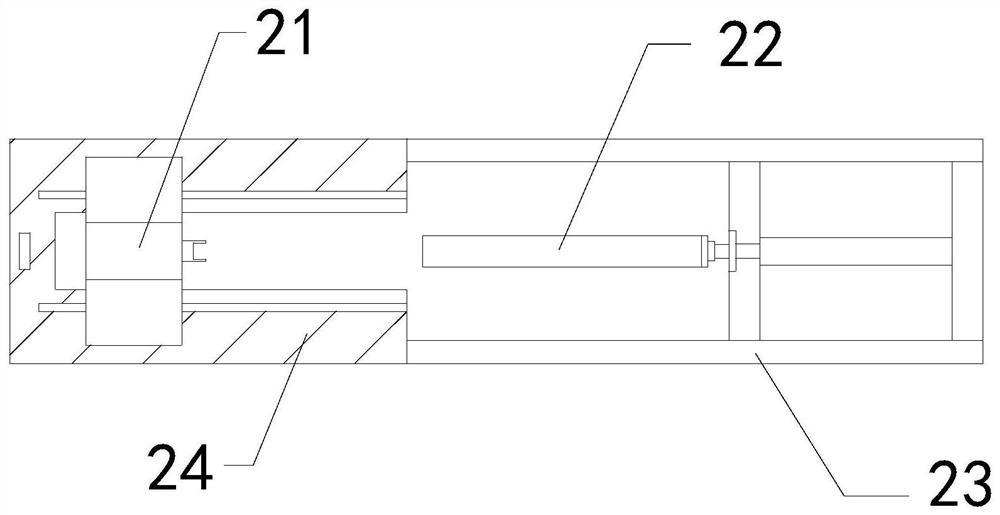

[0029] The invention provides a strength detection device for steel preparation, the structure of which includes a driver 1, an operation table 2, a display table 3, and a support frame 4, the driver 1 is installed on the upper end of the operation table 2, and the display table 3 is embedded in the The inner position of the support frame 4, the bottom of the operating table 2 is welded to the upper end of the supporting frame 4; The frame 21 is installed on the upper surface of the bearing plate 24 , the right side of the pulling tube 22 is connected with the connecting frame 23 , and the left side of the connecting frame 23 is welded with the right side of the supporting plate 24 .

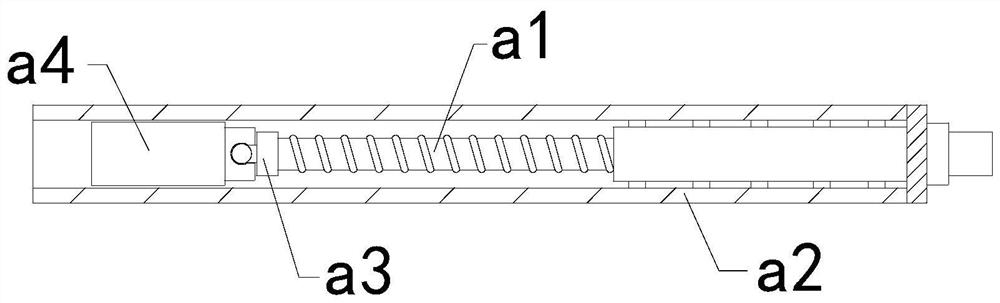

[0030] Wherein, the pulling tube 22 includes a telescopic screw a1, an outer frame a2, a transition block a3, and a sliding sleeve a4, the telescopic screw a1 is connected with the internal thread of the outer frame a2, and the right side...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037]Wherein, the sliding sleeve a4 includes a frame c1, a reverse thrust piece c2, an attraction block c3, and a telescopic plate c4, and the reverse thrust piece c2 is installed between the right side of the inner wall of the frame c1 and the right side of the telescopic plate c4. The attracting block c3 is embedded in the inner position of the frame c1, and the side of the telescopic plate c4 slides and fits with the inner wall of the frame c1. The attracting block c3 is made of permanent magnet material, and the steel telescopic plate c4 can be attracted by the attracting block c3. A suction force is generated, so that the telescopic plate c4 can have a magnetic force.

[0038] Wherein, the telescopic plate c4 includes a rear plate c41, a booster bar c42, a linkage rod c43, and a front push plate c44, and the booster bar c42 is installed on the right side of the front push plate c44 and the right side of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com