Raw material screening equipment for preparing new semiconductor material

A screening equipment and new material technology, applied in solid separation, sieve, grid, etc., can solve problems such as waste, germanium powder is difficult to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

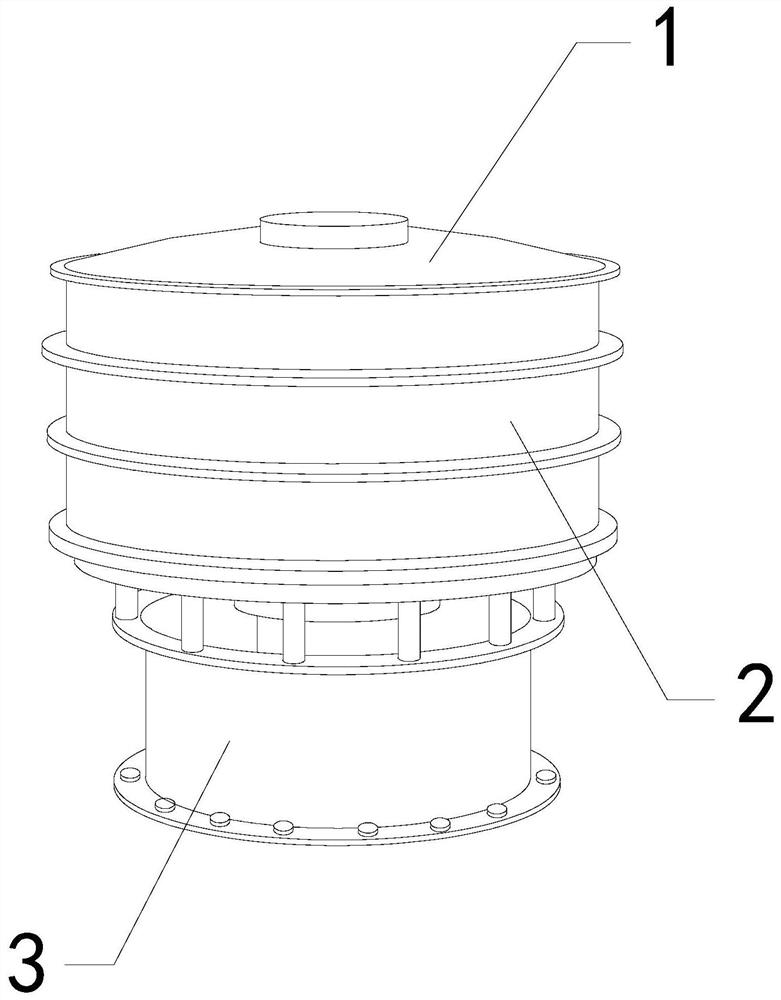

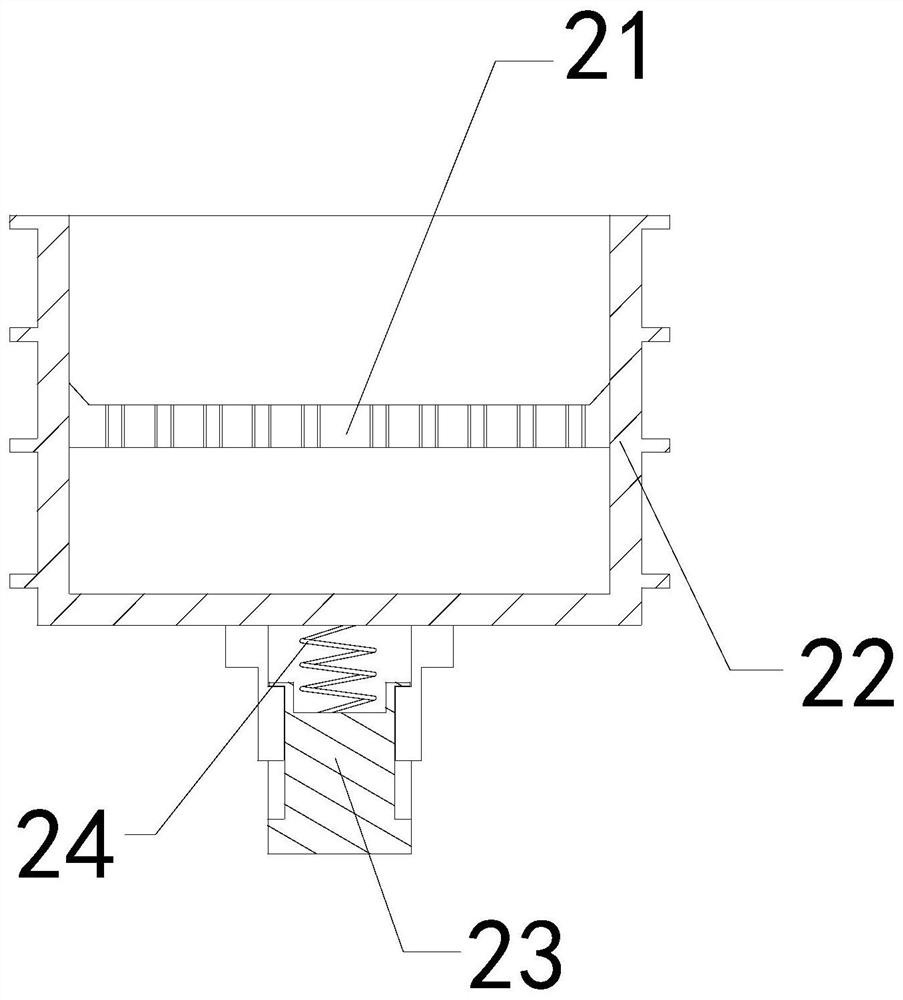

[0029] The invention provides a kind of raw material screening equipment for the preparation of new semiconductor materials. Its structure includes a top cover 1, a screening mechanism 2, and a base 3. The top cover 1 is installed at the top position of the screening mechanism 2. The screening mechanism 2 is installed at the upper end of the base 3; the screening mechanism 2 includes a screening plate 21, a casing 22, a bottoming block 23, and a booster bar 24, and the sides of the screening plate 21 are connected to the inner wall of the casing 22 , the side of the bottoming block 23 is movably engaged with the lower end of the casing 22 , and the booster bar 24 is installed between the top of the bottoming block 23 and the bottom of the casing 22 .

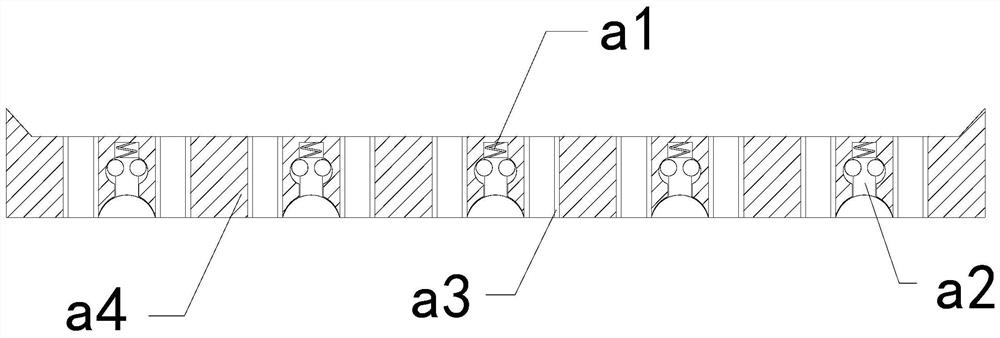

[0030] Wherein, the screening plate 21 includes an elastic strip a1, a telescopic block a2, a powder penetration hole a3, and a plate body a4, and the elastic strip a1 is...

Embodiment 2

[0036] For example Image 6 -example Figure 9 Shown:

[0037] Wherein, the air-permeable cavity b2 includes an outer tube c1, a reset piece c2, and a force plate c3, and the reset plate c2 is installed between the inner side of the force plate c3 and the inner wall of the outer tube c1, and the force plate c3 and The inner part of the outer tube c1 is movable, and there are two stress plates c3, which are evenly distributed symmetrically on the inside of the outer tube c1. The airflow extruded downward by the mechanism can make the force plate c3 move The tube c1 slides and expands to both sides, so that the airflow can be discharged downward through the gap between the two force plates c3.

[0038] Wherein, the force receiving plate c3 includes a positioning block c31, a blocking brush c32, a rear plate c33, and a connecting block c34, the left side of the positioning block c31 is attached to the right side of the rear plate c33, and the The blocking brush c32 is embedded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com