Plate turnover machine on brick pressing machine

A technology of brick press and panel turning machine, which is applied in the field of panel turning machine, and can solve the problems of large dust, unfavorable health of operating workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

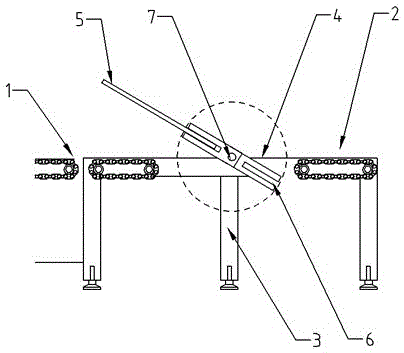

[0011] attached figure 1 Indicates a plate turning machine on a brick press, located between the end of the main conveying line (1) of the brick press and the beginning of the second conveying line (2), composed of a plate turning frame (3), a pivoting arm lever (4 ) is composed of; it is characterized in that: there are two pivoting arms (4), and both ends of each pivoting arm are symmetrically and consistently opened with deep grooves (6) adapted to the thickness of the clamping plate (5); The two pivoting arms (4) are arranged in parallel, and the middle is fixed on the same turning shaft (7), so that the deep grooves (6) at the same end of the two pivoting arms (4) are combined into a double clamping port; The turning shaft (7) is installed on the turning frame (3), and the rotation is controlled by the driving motor; the static position of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com