High-pressure gas-filled connection pipe defect detection method

A technology of inflatable connection and defect detection, which is applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc. It can solve the problems of low detection efficiency, side measurement of size, scrapping of connecting pipes, etc., and simplify the detection process , improve detection efficiency, and visually observe the effect of size defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

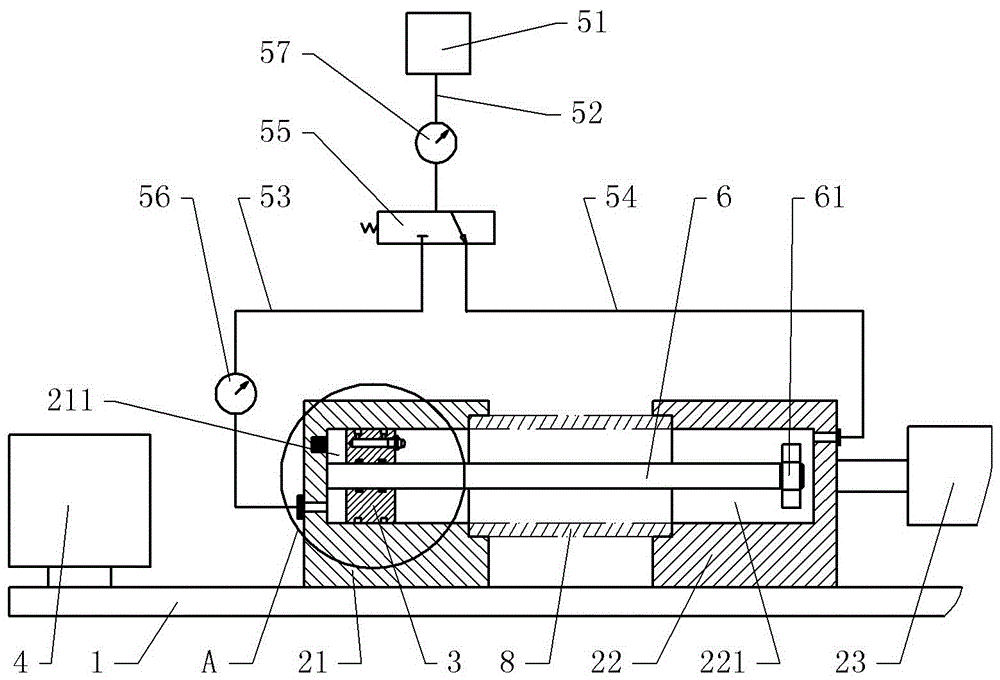

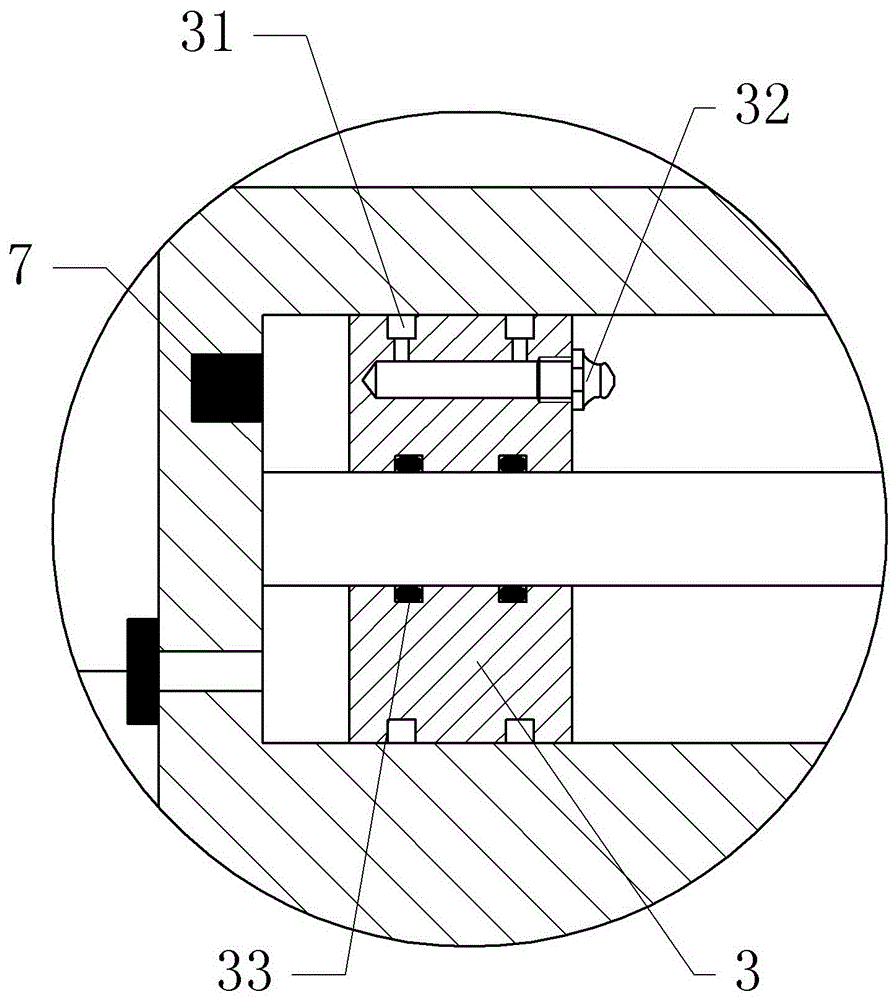

[0036] The reference signs in the drawings of the description include: frame 1, first sealing block 21, second sealing block 22, cavity one 211, cavity two 221, compression cylinder 23, detection piston 3, annular oil groove 31, pressure Oiling cup 32, sealing ring 33, display screen 4, quantitative pump 51, intake main pipe 52, intake branch pipe 1 53, intake branch pipe 2 54, reversing valve 55, pressure gauge 56, flow meter 57, slide bar 6, Limit nut 61, distance sensor 7, connecting pipe 8.

[0037] The embodiment is basically as figure 1 , figure 2 Shown:

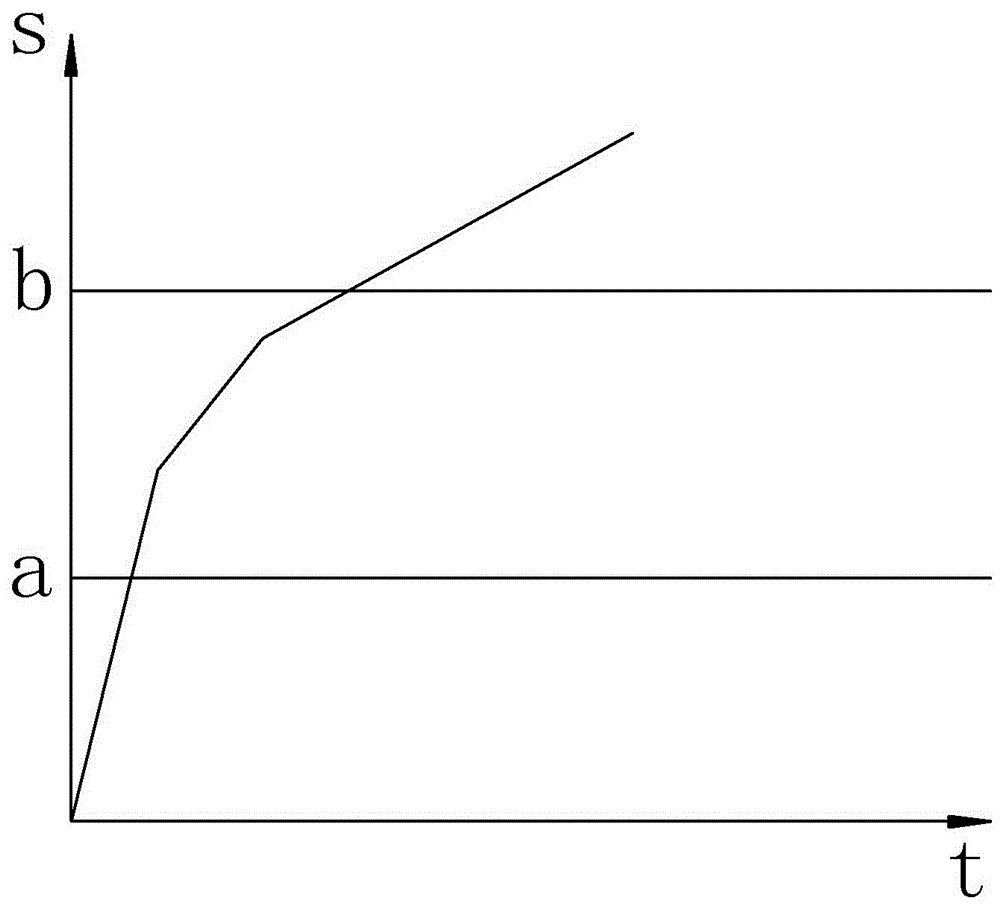

[0038] The defect detection method of the high-pressure inflatable connecting pipe in this embodiment provides a defect detecting device for the high-pressure inflatable connecting pipe, including a frame 1 , a sealing part, a flow control part, a standard block 3 and a display screen 4 . Both the sealing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com