Method for correcting Klinkenberg permeability of tight sandstones based on pore-throat structures

A technology of Kjeldahl permeability and correction method, applied in the field of correction of tight sandstone Kjeldahl permeability, can solve the problems of difficult realization, time-consuming, small net outlet pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

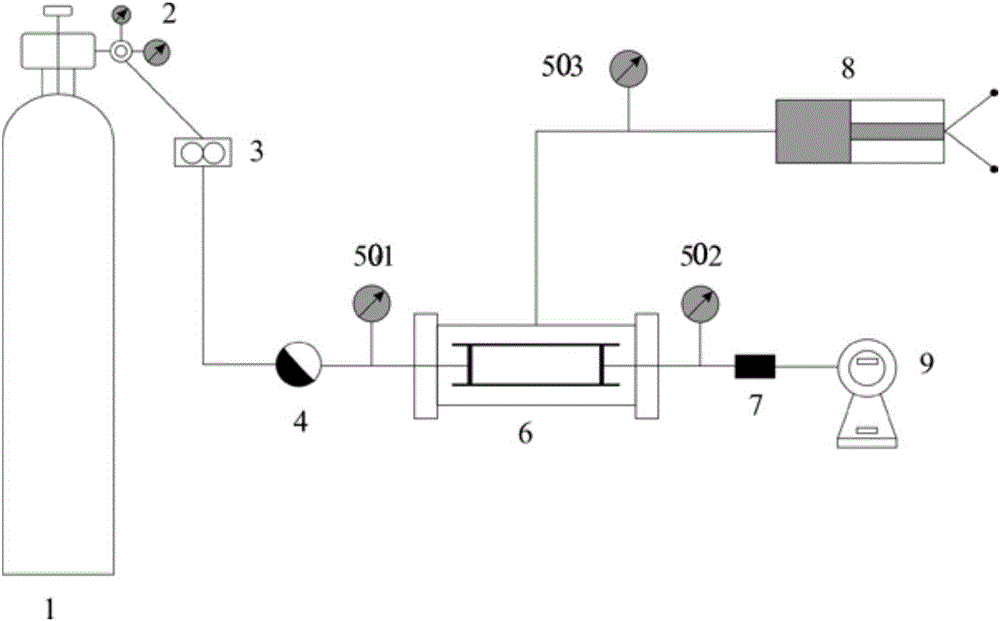

[0058] This embodiment provides a correction method for tight sandstone K-permeability based on pore-throat structure, and the correction method specifically includes the following steps:

[0059] 1. Preparation of rock core;

[0060] Drill the natural core and number it; cut the core and grind the end surface to ensure that the core diameter is 25mm and the length is between 60-70mm; use a Soxhlet extractor to wash oil for a period of one to two months, and use a UV analyzer to check during the period Oil washing effect, if the core is not washed, it will emit white fluorescence when soaked in 365nm ultraviolet light, in this case continue to wash oil until it is washed;

[0061] Dry the rock sample to constant weight, the temperature is controlled at 104°C, and the drying time is not less than 8 hours. After 8 hours, weigh once every 1 hour, and the difference between the two weighings is less than 10mg;

[0062] Measure the core length with a vernier caliper;

[0063] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com