Contact lenses restoration instrument

A contact lens and seat technology, which is applied in the directions of glasses/protective glasses, glasses/goggles, instruments, etc., can solve the problems of large volume and mass of cleaning devices, inconvenient to carry and use, affecting the service life, etc., and achieves reasonable structural design, Easy to use and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

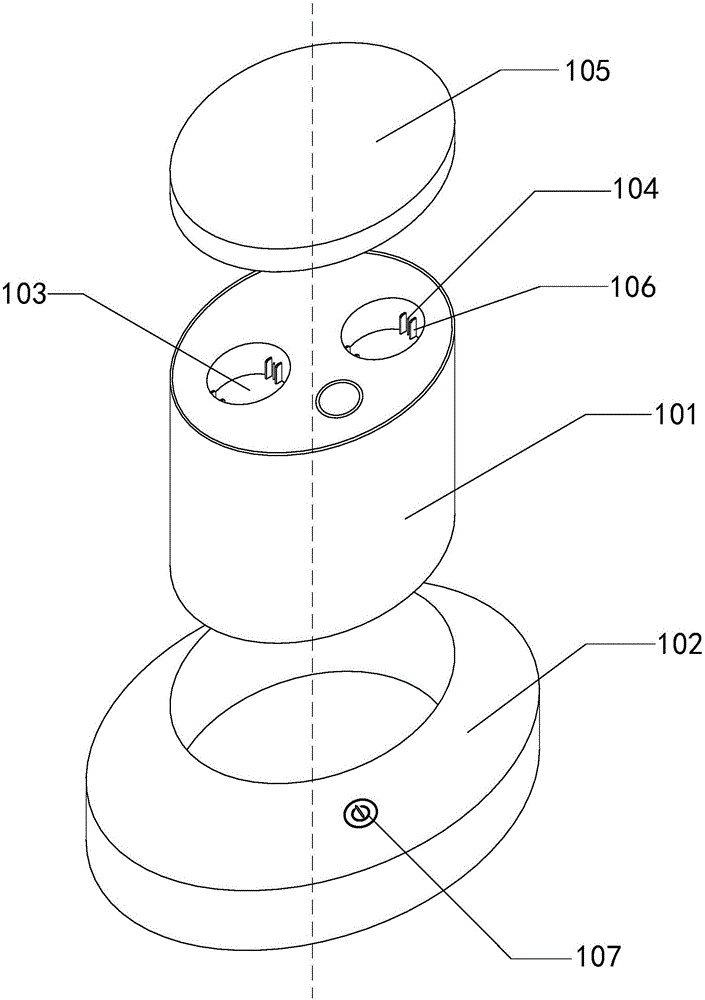

[0041] See figure 1 A contact lens restoration instrument according to a preferred embodiment of the present invention includes a cleaning base 101, a power base 102, and a circuit mechanism. The cleaning base 101 is one, and the cleaning base 101 is provided with two cleaning tanks 103 A pair of electrodes 104 are provided in the cleaning tank 103. The shape of the electrode 104 is needle-like. The circuit mechanism is set in the power supply base 102. The cleaning base body 101 is plugged into the power supply base 102, and the electrode 104 is connected to the circuit through electrical connection elements. The mechanism is electrically connected, and the circuit mechanism is used to apply a potential difference between the electrodes 104 on both sides of the cleaning tank 103; the cleaning base 101 is also provided with a tank cover 105.

[0042] The cleaning tank 103 is provided with a baffle 106 for blocking contact between the contact lens and the electrode 104. The baffle ...

Embodiment 2

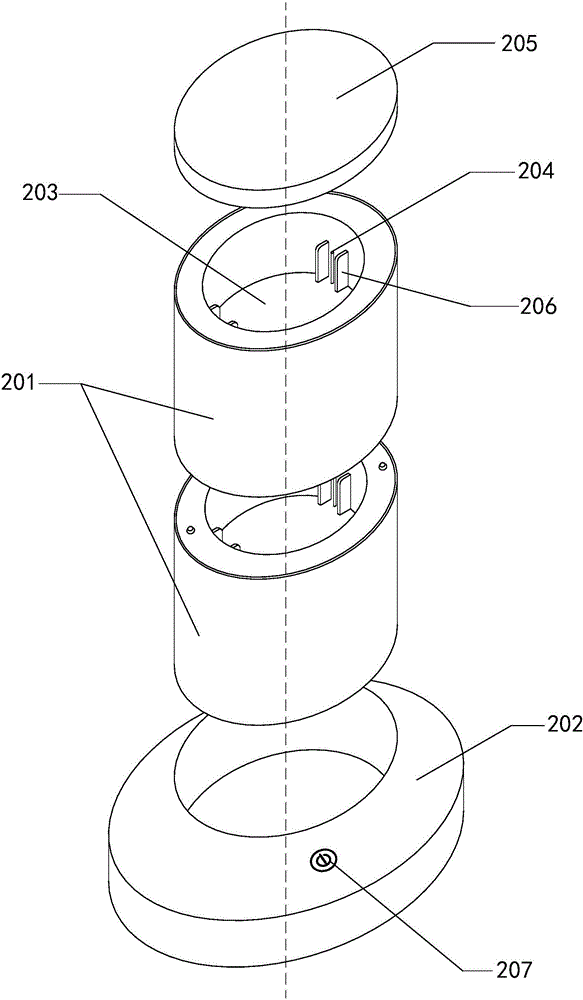

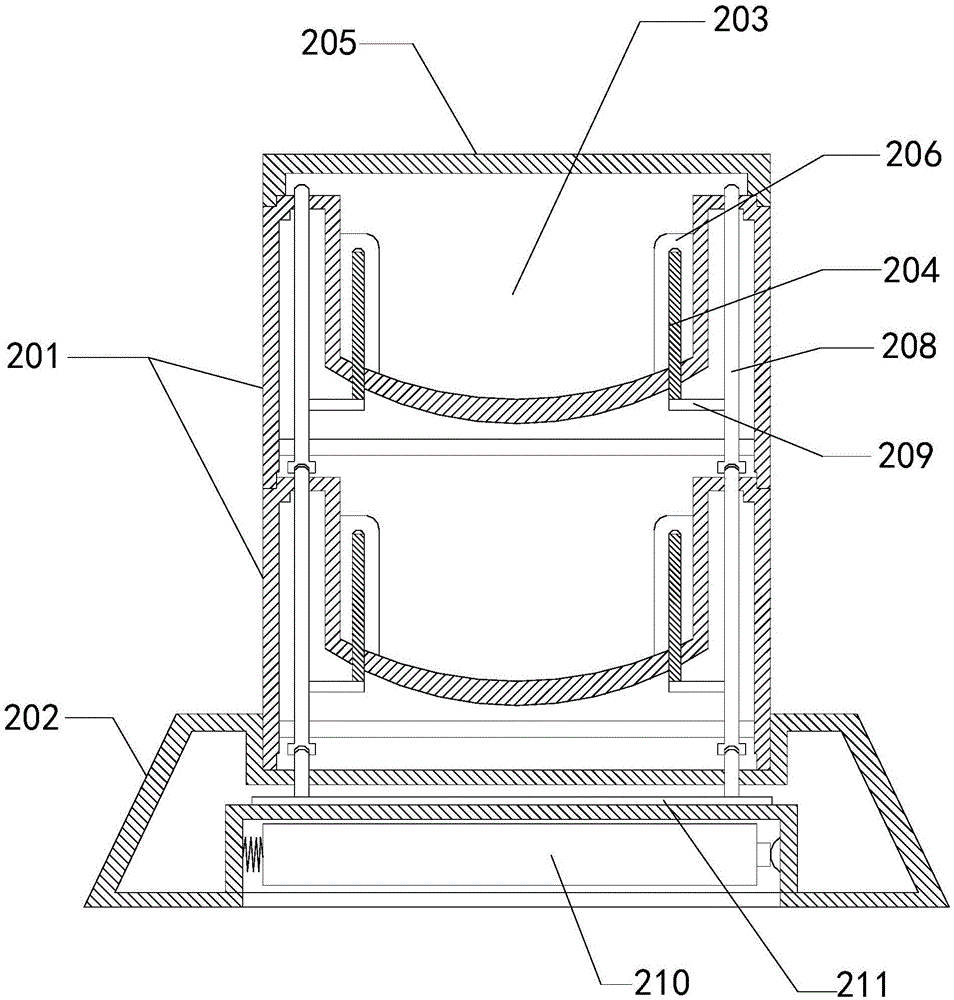

[0046] See figure 2 with image 3 , A contact lens restoration instrument according to a preferred embodiment of the present invention includes a cleaning base 201, a power base 202 and a circuit mechanism. There are two cleaning bases 201, and each cleaning base 201 is provided with a cleaning A pair of electrodes 204 are arranged in the cleaning tank 203. The shape of the electrode 204 is columnar. The circuit mechanism is arranged in the power supply base 202. After the two cleaning base bodies 201 are superimposed and installed on each other, they are plugged into the power supply base 202 and pass the electricity. The connecting element electrically connects the electrode 204 with the circuit mechanism. The circuit mechanism is used to apply a potential difference between the electrodes 204 on both sides of the cleaning tank 203; the cleaning seat 201 is also provided with a tank cover 205.

[0047] A baffle 206 for blocking contact between the contact lens and the electrode...

Embodiment 3

[0052] See Figure 4 A contact lens restoration apparatus according to a preferred embodiment of the present invention includes a cleaning base 301, a power base 302, and a circuit mechanism. There are two cleaning bases 301, and a cleaning tank 303 is provided on the cleaning base 301 A pair of electrodes 304 are provided in the cleaning tank 303. The shape of the electrode 304 is columnar. The circuit mechanism is set in the power supply base 302. After the two cleaning base bodies 301 are superimposed on each other, they are accurately abutted by the guide parts provided on the side of the power supply base. On the side of the power base 302, the electrode 304 is electrically connected to the circuit mechanism through electrical connection elements. The circuit mechanism is used to apply a potential difference between the electrodes 304 on both sides of the cleaning tank 303. The cleaning base 301 is also provided with a tank cover 305 .

[0053] For example, the side of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com