Oil-immersed transformer online oil change device and system

An oil-immersed transformer and oil system technology, applied in the field of electric power, can solve problems such as poor oil change effect, no solution proposed, loss of meaning of oil change, etc., and achieve the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

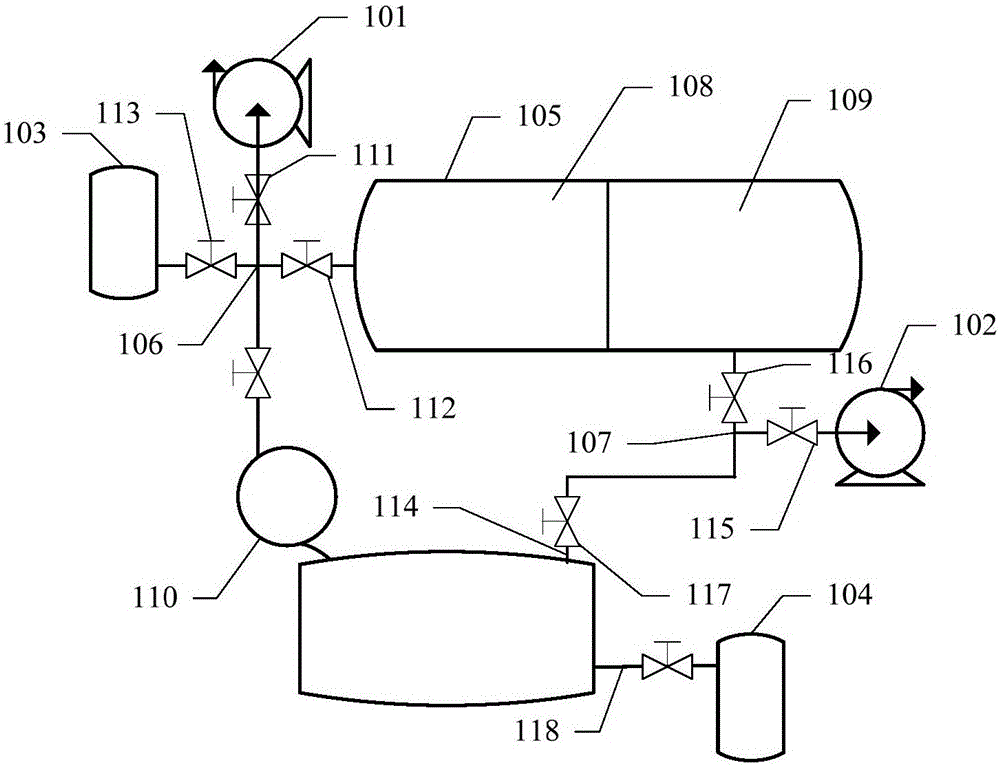

[0031] Embodiment 1 of the present invention provides an oil-immersed transformer online oil change device, which performs oil change operations on running transformers, see figure 1 The schematic diagram of the structure of the oil-immersed transformer on-line oil change device shown, the on-line oil change device includes: a first vacuum pump 101, a second vacuum pump 102, a new oil tank 103, a waste oil tank 104, an inert gas tank 105, and a four-way connector 106 and tee joint 107.

[0032] Among them, the new oil tank 103 is used to store new transformer oil, preferably airtight storage, to keep the transformer oil from being oxidized by the air; the waste oil tank 104 is used to store the waste oil flowing out of the transformer in the oil change operation; the inert gas tank 105 is used for Store inert gas. Considering that the gas used as the medium before and after oil change may pollute the air, the inert gas tank 105 includes an independent first air chamber 108 an...

Embodiment 2

[0040] Embodiment 2 provides an online oil change system for an oil-immersed transformer, including the online oil change device provided in Embodiment 1 above, and the online oil change device is connected to an oil-immersed transformer requiring oil change.

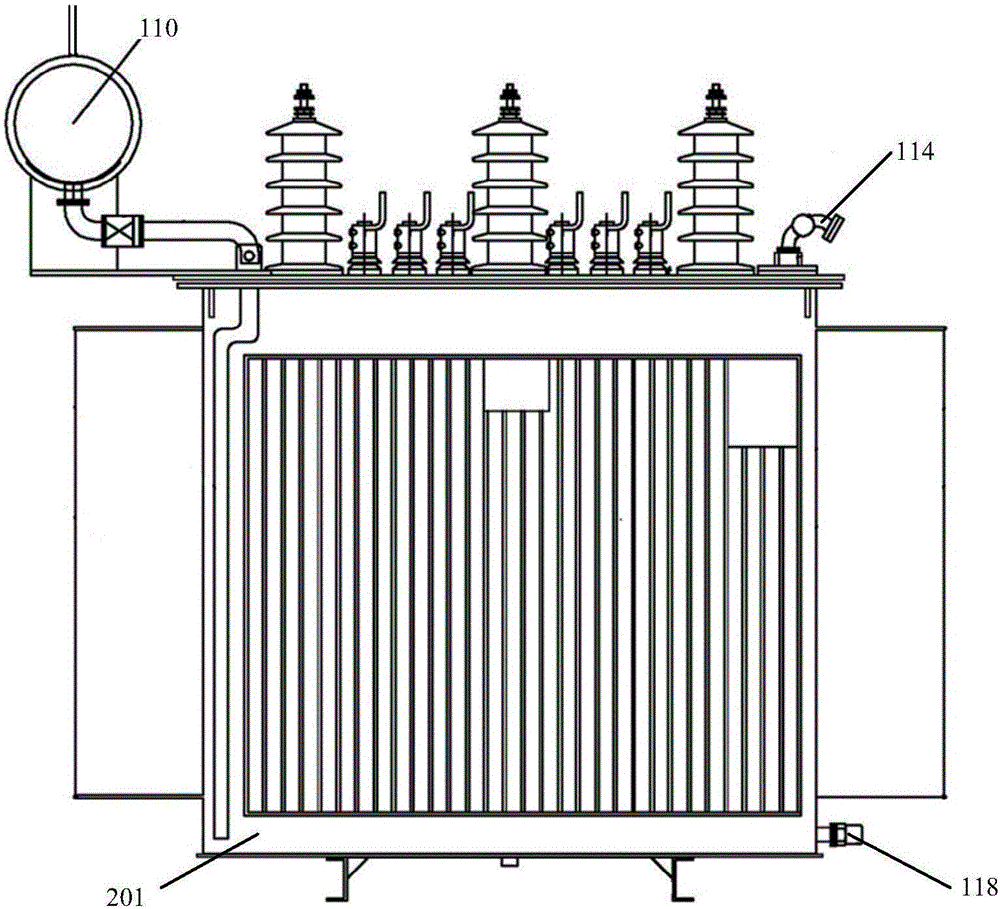

[0041] see figure 2 The schematic diagram of the external structure of the oil-immersed transformer is shown, wherein the oil-immersed transformer includes a transformer main body 201 and an oil conservator 110 communicating with it, an exhaust pipe 114 and an oil discharge pipe 118, and the oil conservator 110 is also provided with an oil injection pipe.

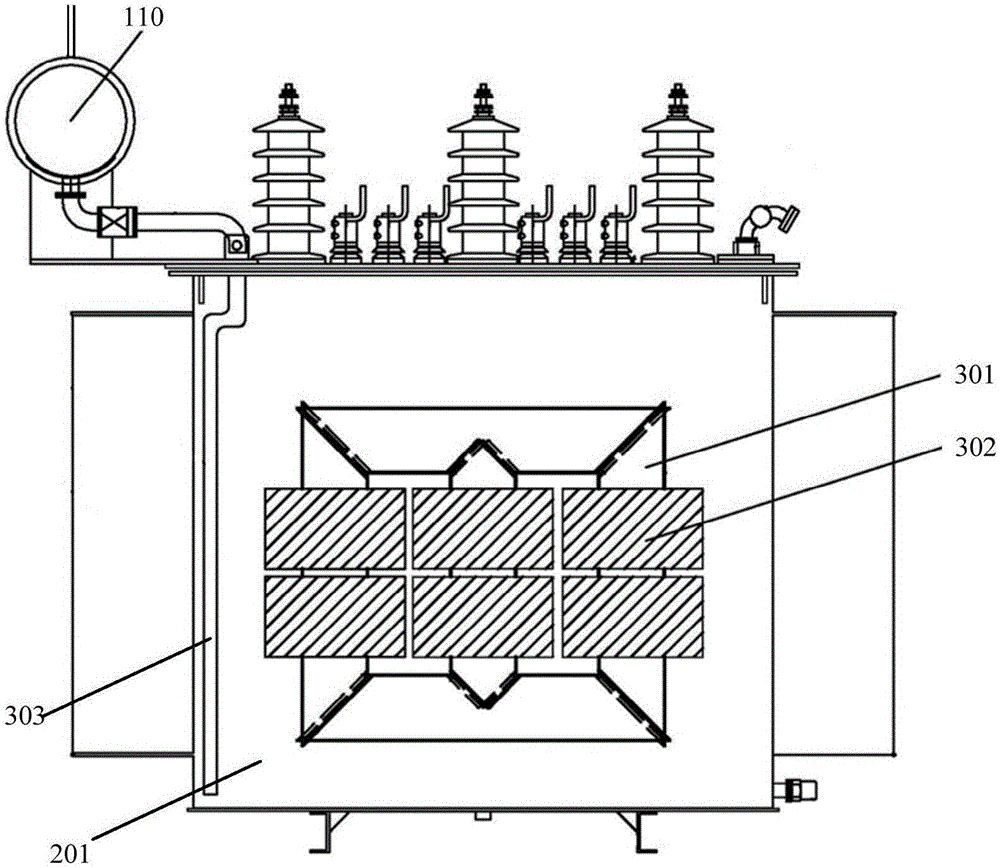

[0042] see image 3 The shown schematic cross-sectional structure of the oil-immersed transformer shows that an iron core 301 is provided in the main body 201 of the transformer. In this embodiment, an axial double-split winding is used as an example. The actual transformer may be of other types. The iron core 301 includes three iron core columns, and each iron cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com