Vacuum arc extinguish chamber with composite shielding structures

A vacuum interrupter and composite shielding technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems that are not conducive to the maintenance-free performance of metal-enclosed switchgear, lengthen the production cycle of vacuum interrupters, and increase vacuum interrupters. Arc chamber production cost and other issues, to achieve the effect of improving environmental protection and economic performance, conducive to heat dissipation, and shortening the design length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

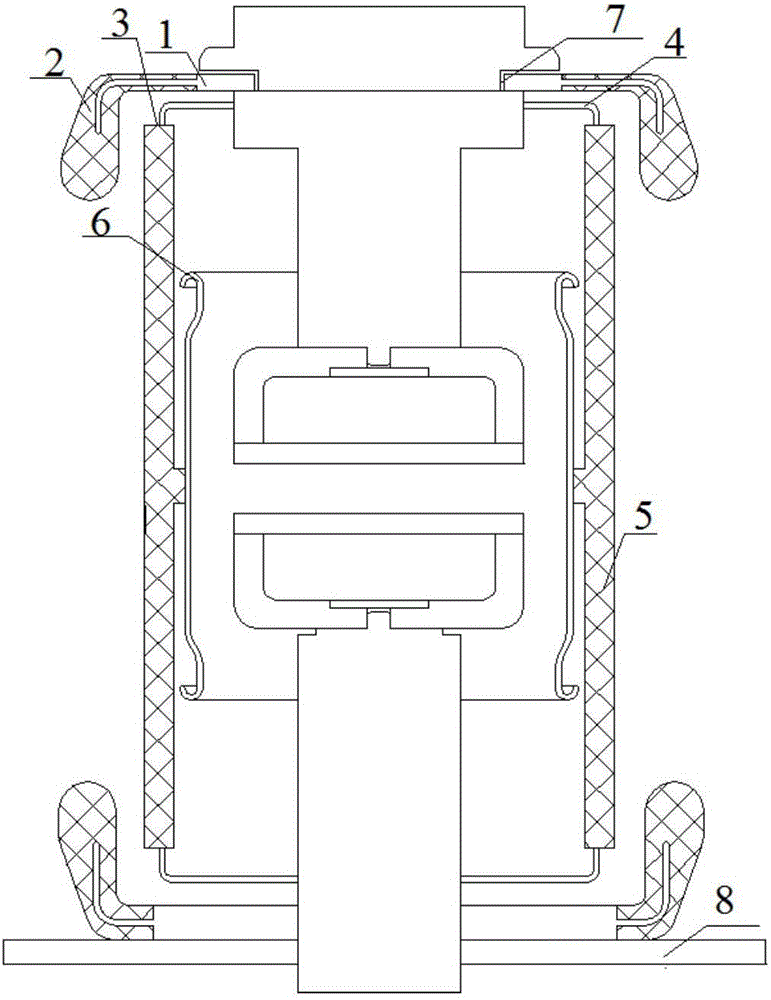

[0018] The present invention is a vacuum interrupter with composite shielding structure, such as figure 1 As shown, it includes a vacuum interrupter and a composite shielding structure arranged and implemented on the periphery of the upper and lower ends of the vacuum interrupter; the front end of the metal shield 1 in the composite shielding structure, that is, the outer edge end must exceed the metal seal The face 3 has a certain size; in this preferred embodiment at least exceeds 1 mm.

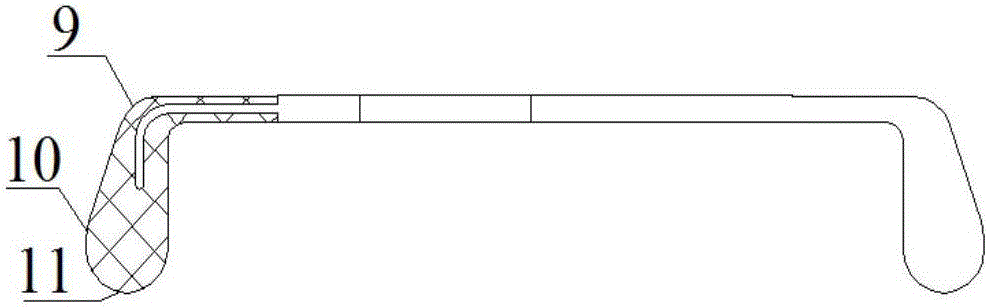

[0019] Among them, the composite shielding structure includes a metal shielding case 1 and an epoxy resin dielectric 2, which is formed by integral casting of the metal shielding case 1 and the epoxy resin dielectric 2; the front end of the metal shielding case 1 is coated with a certain thickness of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com