Socket

A technology for sockets and components, applied in the field of sockets that use a screwdriver to connect wires, can solve problems such as poor connection of wires, wrong insertion, etc., achieve the effects of enhanced support strength, firm structure, and improved assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

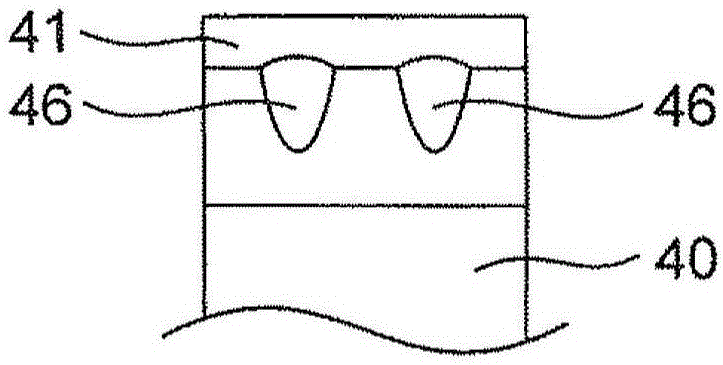

[0077] Such as Figure 15 and Figure 16 As shown, the stress distribution when the middle region of the compression spring 35 of the spring member 30 according to the above-mentioned embodiment is pressed down by an operating screwdriver 50 to elastically deform the middle region of the compression spring 35 is analyzed. Analysis results such as Figure 17 shown.

[0078] From Figure 17 It is clearly judged from the figure that the internal stress tends to concentrate on the bent portion 36 of the spring member 30 , especially on the side of the riveted portion 31 of the bent portion 36 .

[0079] In addition, if Figure 17 As shown, in the above-mentioned embodiment, the conical surface 16 for limiting is provided so that the crimping spring 35 of the spring member 30 is in contact with the conical surface 16 for limiting the protrusion 15 within the range of elastic deformation. Abut. Therefore, plastic deformation of the crimping spring 35 can be prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com