Automatic wire cutting peeling double pressing single pass plastic case machine

A fully automatic, molding machine technology, applied in the assembly/disassembly of circuit/collector parts, contact parts, electrical components, etc., can solve the problems of low production efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

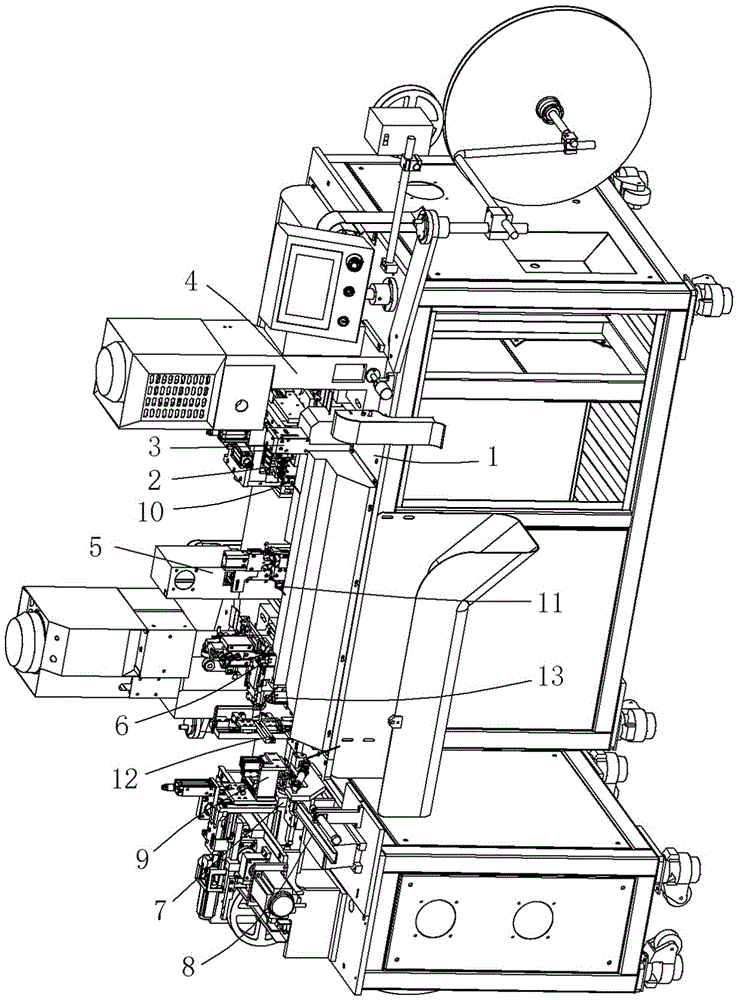

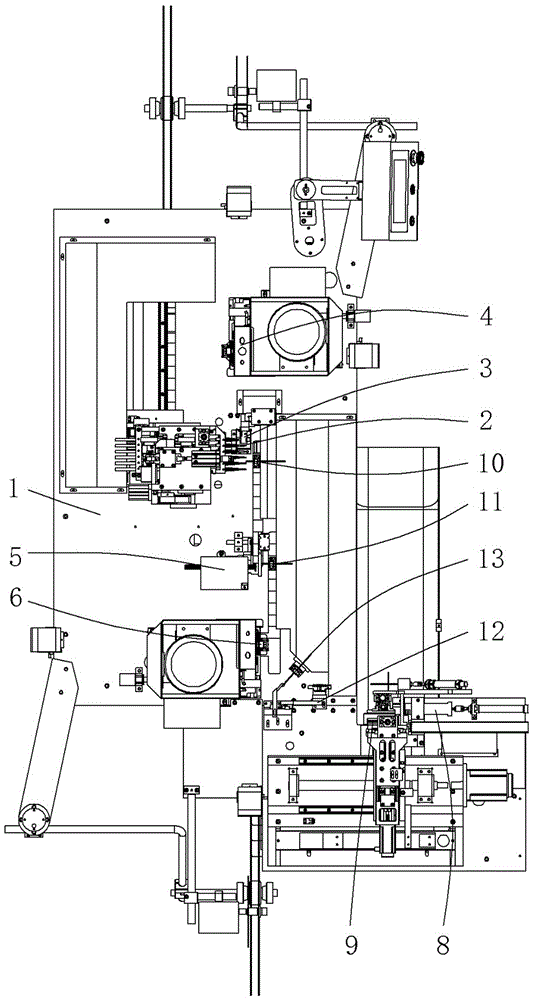

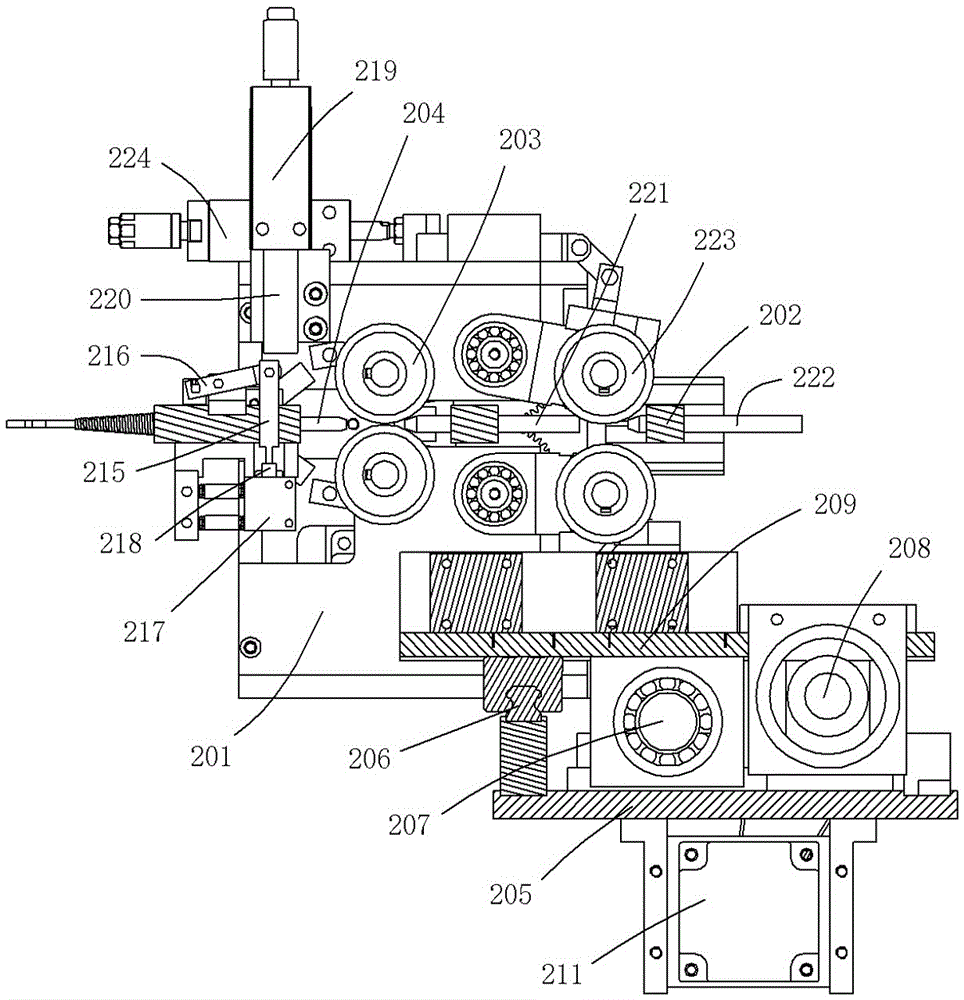

[0038] refer to Figure 1~Figure 8 , a full-automatic tangential peeling double-pressure single-pass molding machine, including a workbench 1, a multi-line conveying mechanism 2 for conveying multiple cables is provided on the workbench, and a pair of The front stripping mechanism 3 that cuts the cable and peels the front end of the cable. One side of the front stripping mechanism is provided with a front terminal crimping mechanism 4 that presses the terminal on the front end of the cable. The front stripping mechanism The other side of the cable is provided with a rear stripping mechanism 5 for stripping the rear end of the cable. Next to the rear stripping mechanism is a rear terminal crimping mechanism 6 for pressing the terminal on the rear end of the cable. The front stripping mechanism Mechanism, rear peeling mechanism, front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com