front load washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machine control devices, washing devices, etc., can solve the problems of reduced rotation speed, inability to effectively squeeze and wash, and weakened centrifugal force of the drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

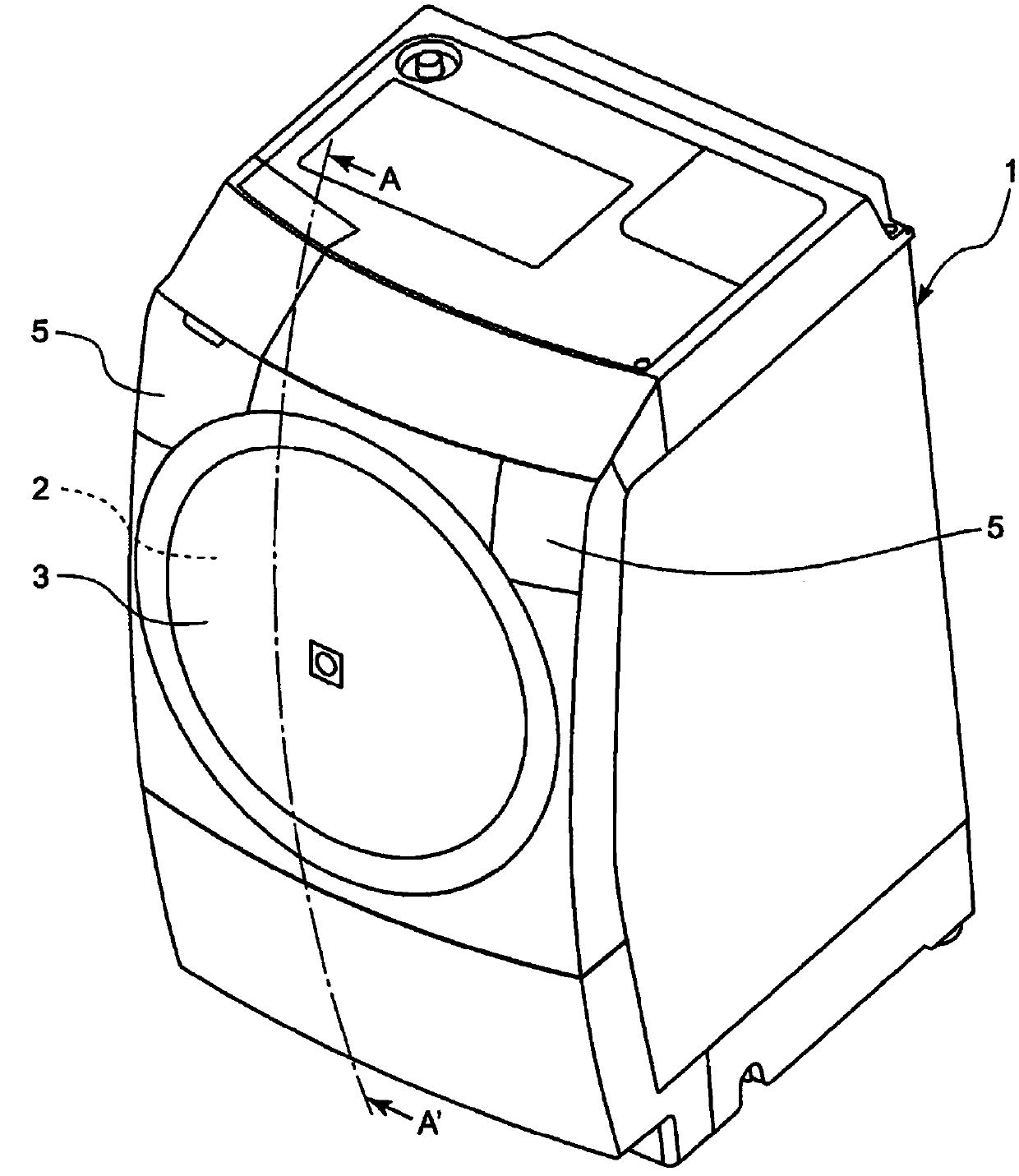

[0040] figure 1 It is a schematic perspective view which looked at the front-loading washing machine of this embodiment obliquely from above.

[0041] Such as figure 1 As shown, the drum type washing machine includes an outer case 1 having an outer case opening 2 at the front.

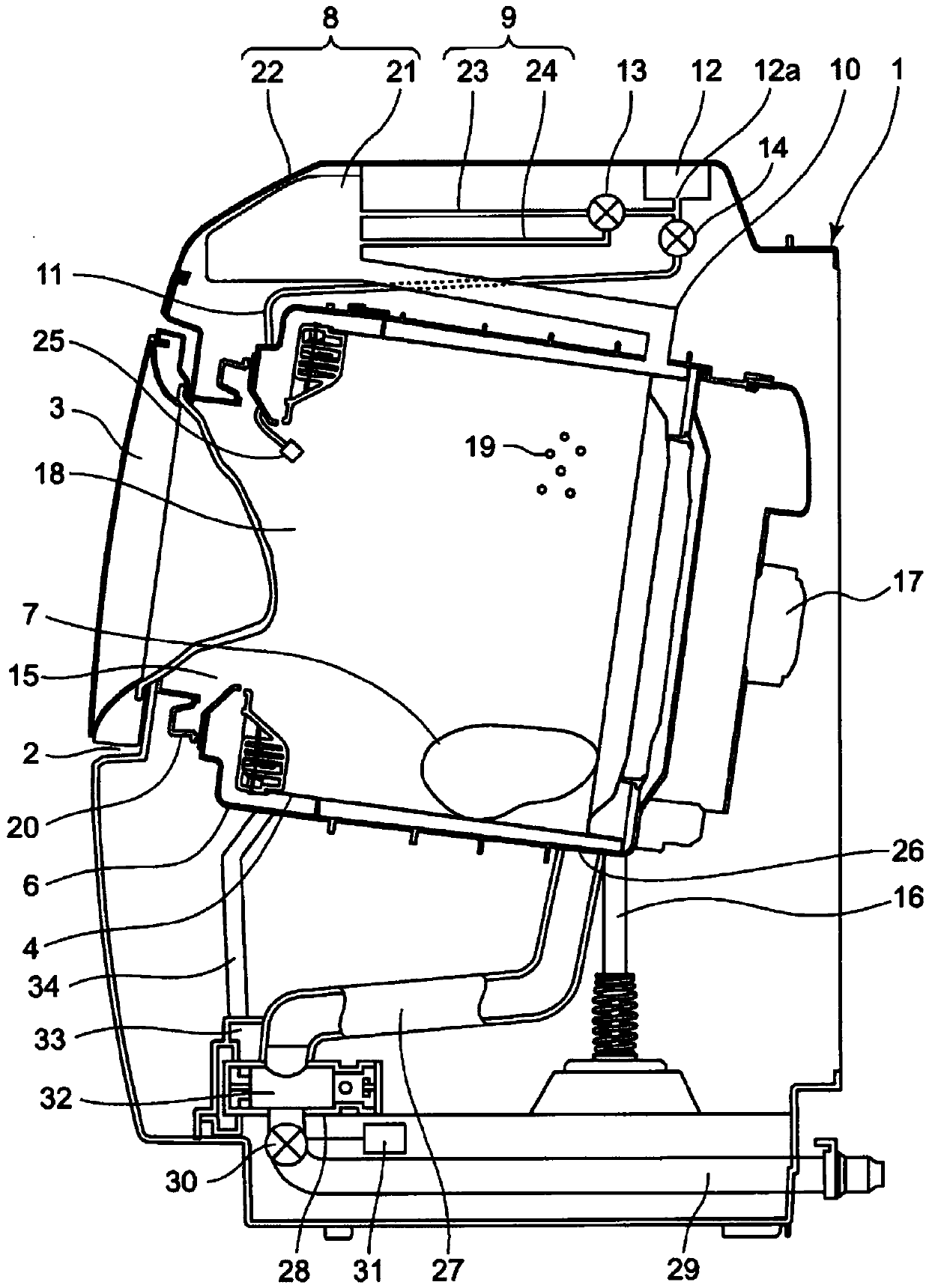

[0042] The outer case opening 2 is opened and closed by a door 3 rotatably attached to the outer case 1 by a hinge. A part of the above-mentioned door 3 is made of transparent members such as glass, so that the drum 4 can be observed (refer to figure 2 )Inside.

[0043] Moreover, the operation display part 5 is provided in the front upper part of the outer case 1. As shown in FIG. The operation display unit 5 has operation keys for specifying operation details, a display unit, etc., and the display unit displays the operation contents determined by the operation keys. The front-loading washing machine performs a washing operation, a rinsing operation, a dehydration operation, etc. by inputting th...

no. 2 approach

[0090] This embodiment relates to the rinsing operation according to the cloth quality and capacity of the laundry. In addition, the basic structure and control block diagram of the front-loading-type washing machine in this embodiment are the same as those in the above-mentioned first embodiment. figure 1 with figure 2 The structure shown and Figure 5 The control block diagram shown is the same. Therefore, in this embodiment, using figure 1 with figure 2 The structure of the drum type washing machine shown and Figure 5 The control block diagram is shown for illustration.

[0091] When the amount of the above-mentioned laundry 7 (hereinafter referred to as the amount of cloth) is small, or when there are many chemical fiber clothes (hydrophobic fibers), in the rinsing process, even if the rotation speed of the drum 4 is lower than that of the first embodiment (that is, the centrifugal force is small), ) state, it is also easy to dehydrate the laundry 7. Therefore, i...

no. 3 approach

[0114] In this embodiment, the rinsing effect of the "water storage rinsing" in the above-mentioned rinsing process is improved and the time is shortened. In addition, the basic structure and control block diagram of the front-loading-type washing machine in this embodiment are the same as those in the above-mentioned first embodiment. figure 1 with figure 2 The structure shown and Figure 5 The control block diagram shown is the same. Therefore, in this embodiment, using figure 1 with figure 2 The structure of the drum type washing machine shown and Figure 5 The control block diagram is shown for illustration.

[0115] In the above-mentioned rinsing process, in the intermediate dehydration (high-speed dehydration after the final spray rinse) performed before the above-mentioned "water storage rinse" in the final stage, if the "water storage" is performed from the deceleration immediately before the end of the intermediate dehydration The water supply for "rinsing" ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com