Housing upper part of labyrinth piston compressor and method for cooling same, and labyrinth piston compressor

A technology for compressors and casings, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of large gap width, leakage, piston wear, etc., and achieve the effect of less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

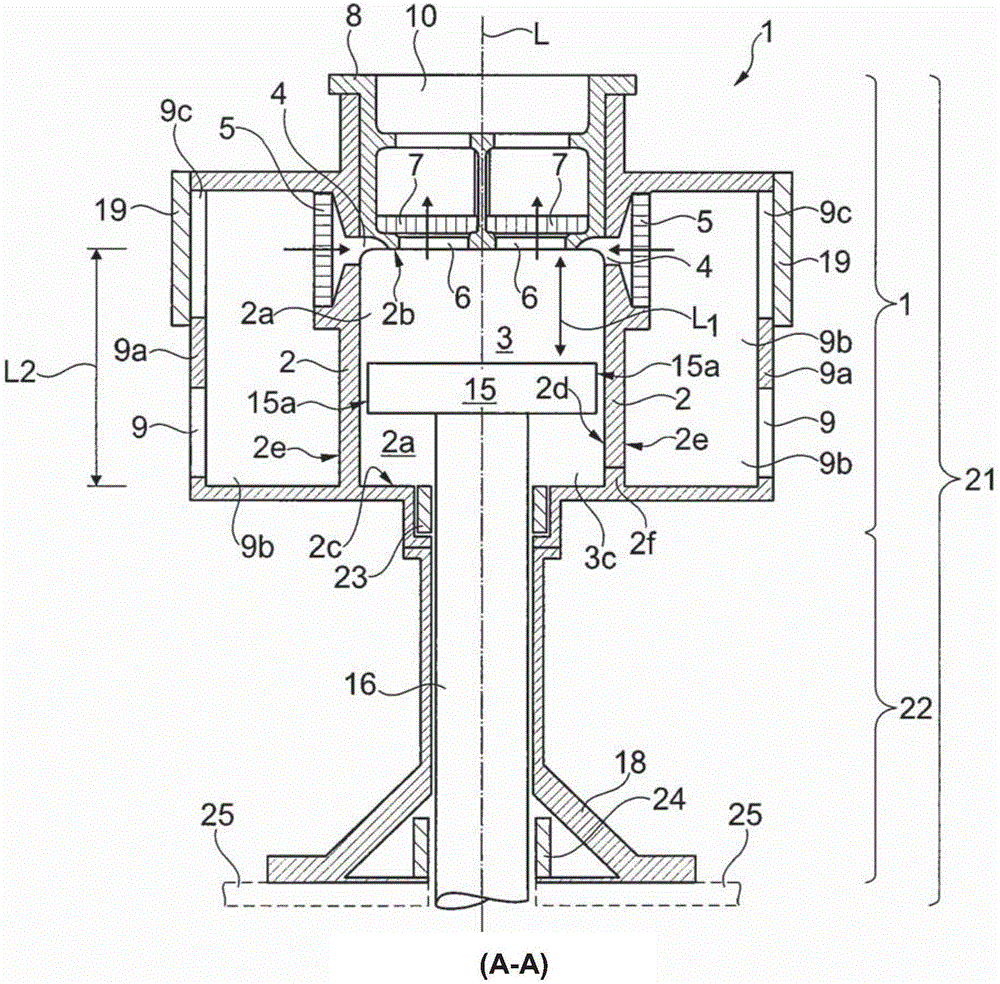

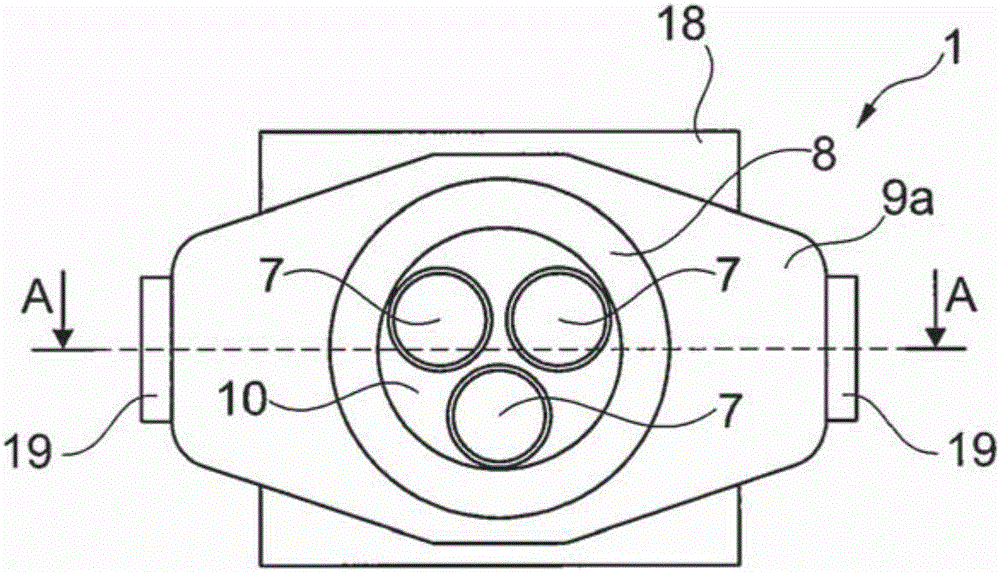

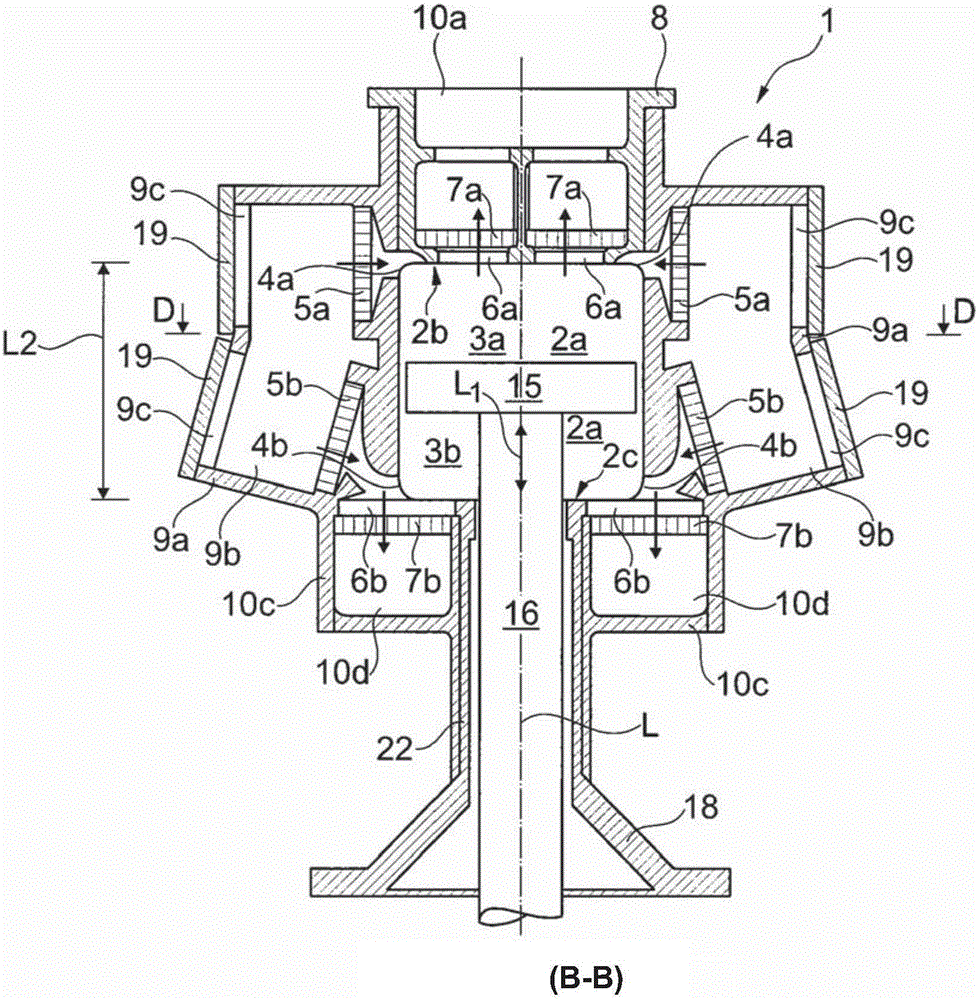

[0029] figure 1 A partial sectional view of a labyrinth piston compressor is shown, which comprises, besides components not shown, a housing upper part 1 , a spacer 22 , a piston 15 with a piston rod 16 , a seal 23 and a linear guide 24 . The housing upper part 1 comprises a cylinder 2 having a cylinder interior 2a extending in the direction of the longitudinal axis L. As shown in FIG. A piston 15 is arranged in the cylinder interior 2 a and is mounted such that it is displaceable together with the piston rod 16 in the direction of the longitudinal axis L in the direction of movement L1 . The piston 15 has, on the peripheral surface forming the side surface 15 a , a thin groove, not specifically shown, extending in the circumferential direction. The cylinder barrel 2 comprises at least one cylinder inlet 4, which opens into the cylinder interior 2a. In addition, a cylinder outlet 6 is provided on the end surface of the cylinder chamber 2a. The cylinder inlet 4 and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com