Welding mechanism for crystal oscillator foot welding forming

A technology of welding mechanism and crystal oscillator, which is applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of high requirements of operators, small size of welding crystal oscillator, and low product qualification rate, so as to improve quality and ensure firmness Accuracy and consistency, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

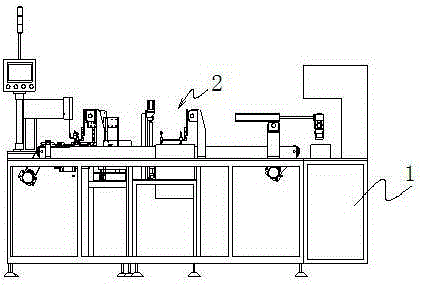

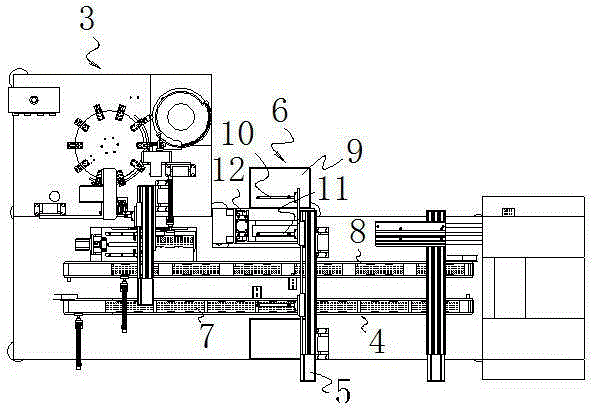

[0012] A welding mechanism for crystal oscillator feet welding and forming, comprising a frame 1, a spot welding device 2 arranged on the frame 1, and a forming device 3 arranged at one end of the spot welding device 2 and connected with the spot welding device 2.

[0013] Spot welding device 2 comprises the conveying device 4 that is arranged on frame 1, is arranged on the spot welding machine 5 that is arranged on conveying device 4 both sides and is arranged on the welding device 6 that is arranged on conveying device 4 one side, and conveying device 4 includes at least one for placing treatment The conveyor belt 8 of the tool 7, in the present embodiment, there are two conveyor belts, which are horizontally arranged on the frame 1, and the spot welding machine 5 is located directly above the conveyor belt.

[0014] The welding device 6 includes a welding frame 9 and a horizontal slide rail 10 which is arranged on the welding frame 9 and is provided with a nut screw transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com