A printing device with automatic side coloring and its operation method

A printing device and automatic coloring technology, used in printing, printing presses, rotary printing presses, etc., can solve the problems of difficult to control the amount of ink, large loss of ink amount, low coloring efficiency, etc., and achieve accurate and controllable inking position. The effect of less ink loss and improved product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

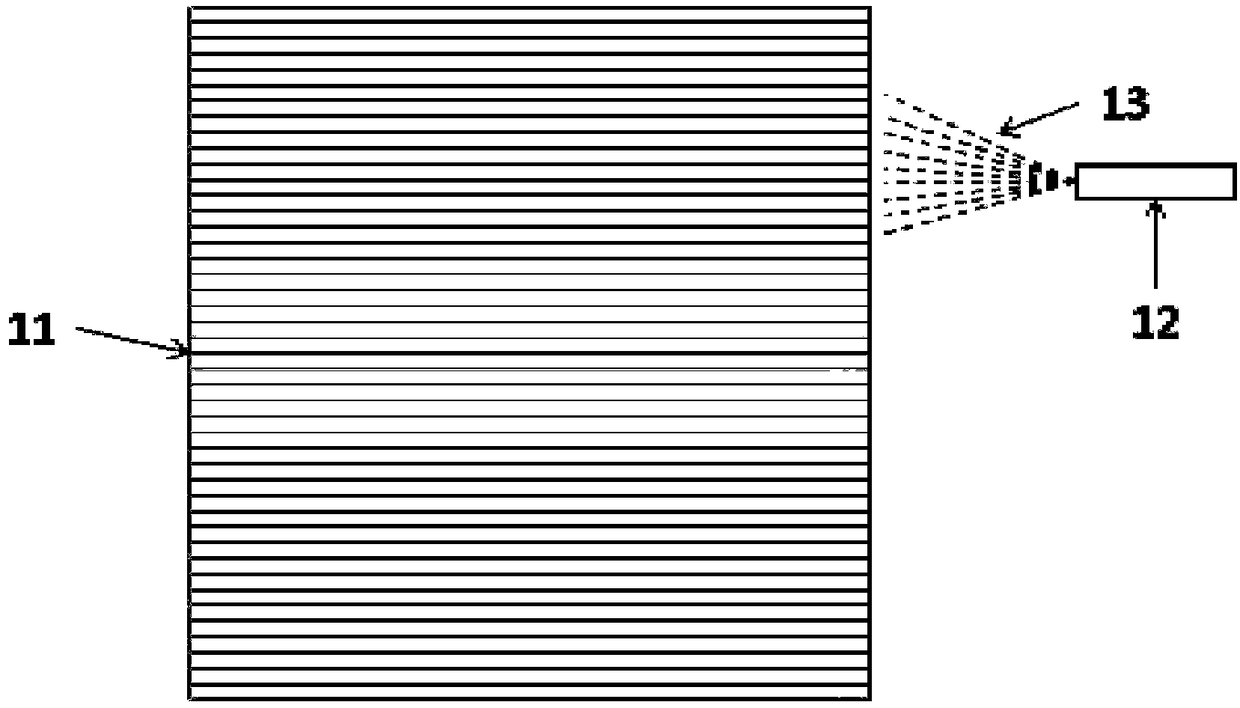

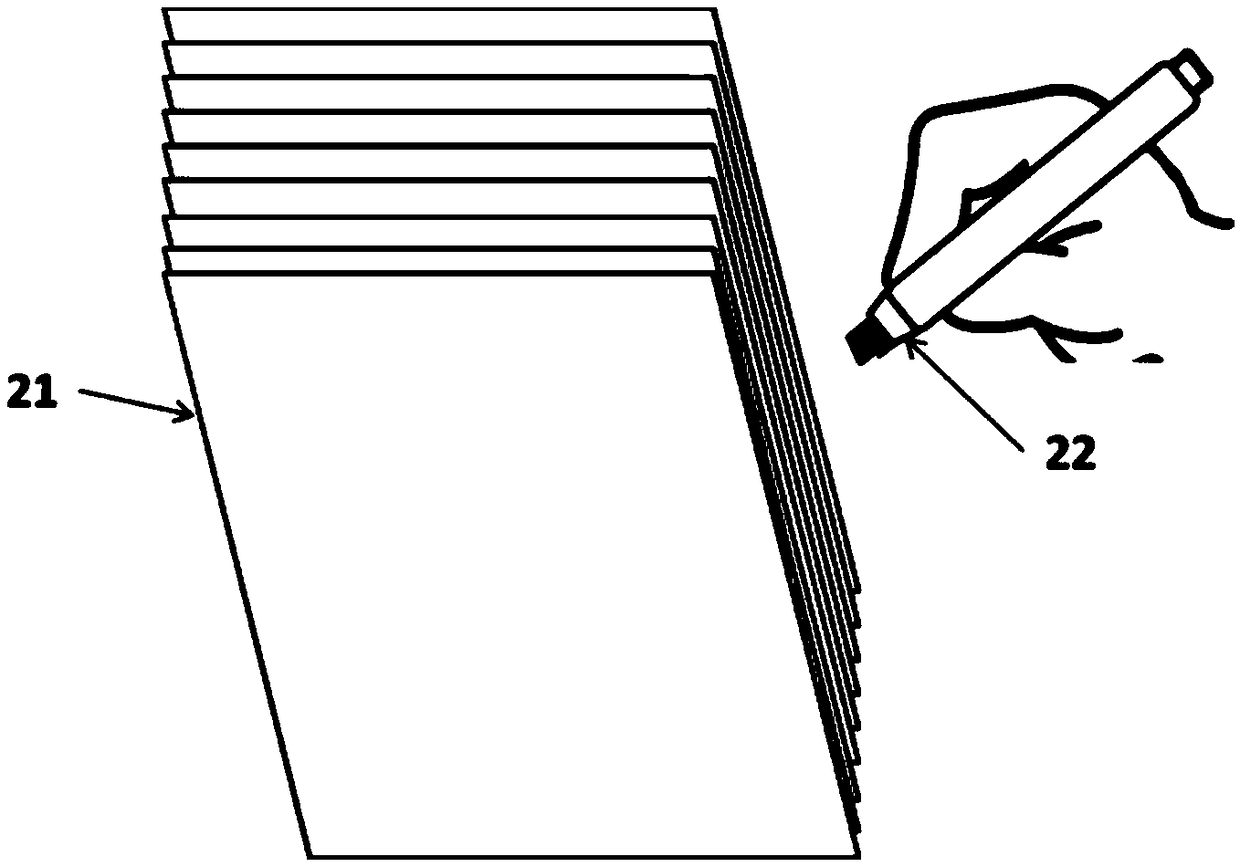

[0038] Such as Figure 3-9 In the specific embodiment shown, a printing device with automatic side coloring provided by this embodiment can be used in the process of coloring paper substrates to achieve uniform coloring of the sides of paper substrates without No dead angle, no waste of ink, no pollution.

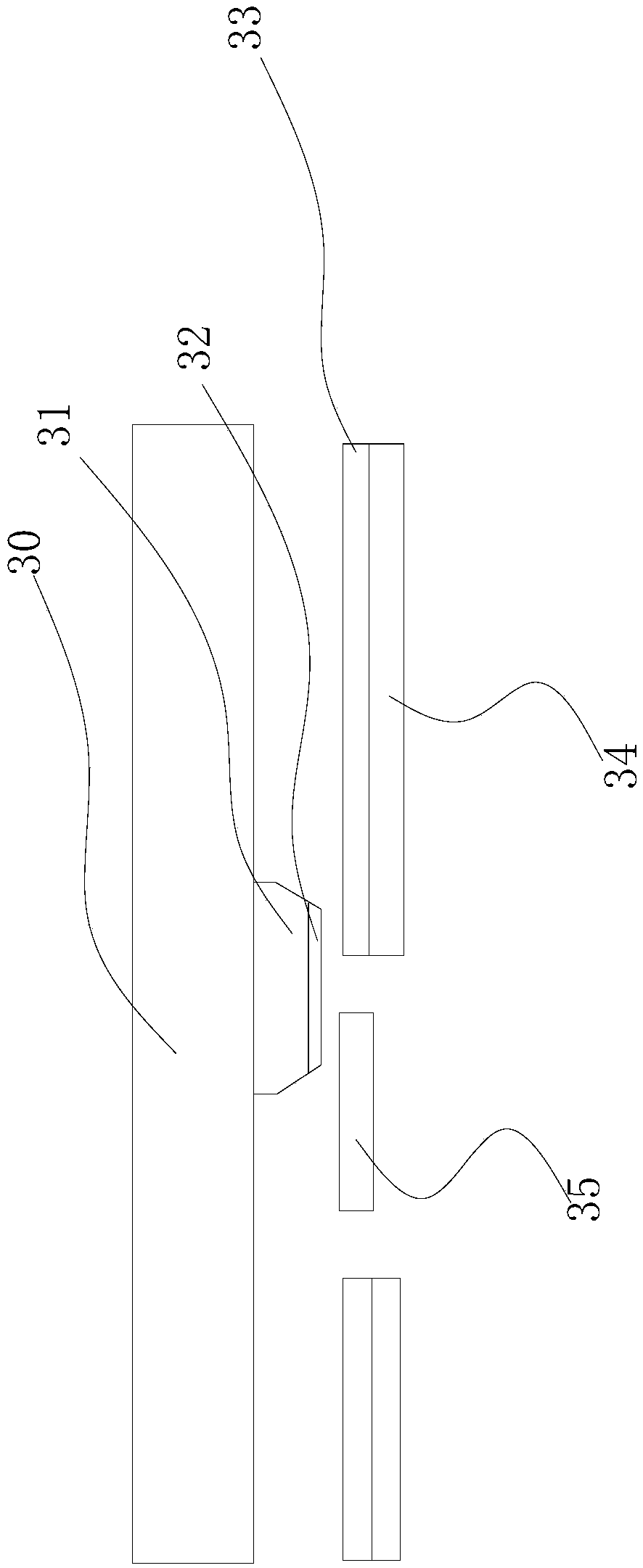

[0039] A printing device 43 for side automatic coloring, comprising a coloring structure 30 and a positioning structure for placing paper substrates 33, the lower end surface of the coloring structure 30 is coated with ink 32, and the positioning structure is provided with paper substrates 33 waste paper 35 is suspended in the gap; the paper substrate 33 is placed in the positioning structure, the waste paper 35 is suspended in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com