A product composed of multiple components

A product and component technology, which is applied in the field of products composed of multiple components, can solve the problems of uniform alloying and uneconomical unsuitable planar areas, and achieve the minimization of the risk of contact corrosion and the lowest risk of contact corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

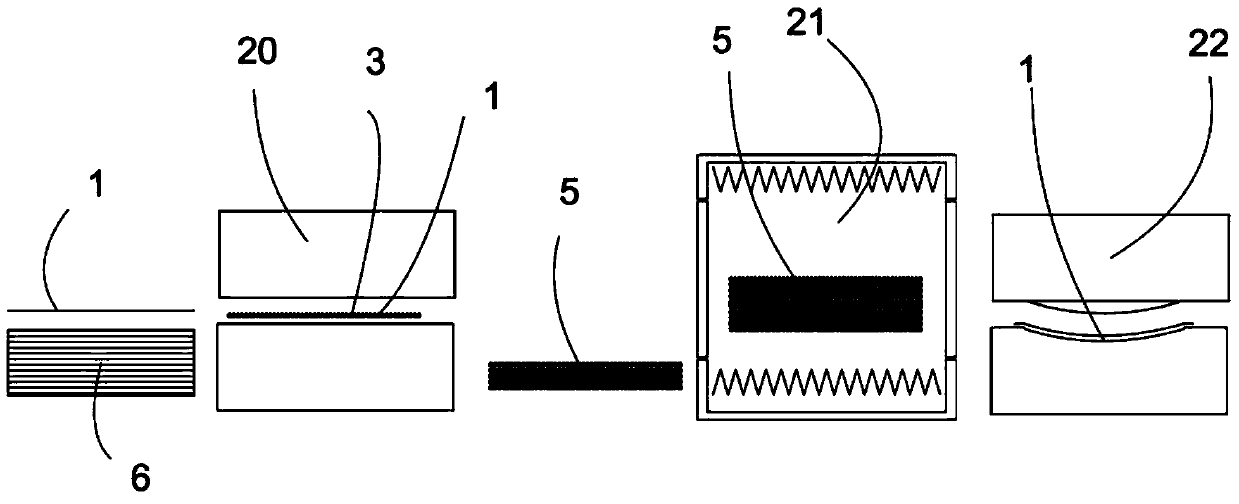

[0030] figure 1 The different stages of the method according to the invention are shown schematically. exist figure 1 In the first stage shown on the left of , the metal sheet to be processed is placed on a stack 6 as flat, sheet-shaped sheet metal cut-offs 1 . The metal sheet 1 consists of low-alloy steel, preferably IF steel (ultra-low carbon steel).

[0031] figure 1 A screen printing machine 20 is shown on the right next to the metal sheet stack 6 , into which the sheet metal cut sections 1 are placed individually from the stack 6 . The amorphous substance is coated on a first area of the surface of each sheet cut section 1 in a screen printing machine 20 . The amorphous mass contains one or more alloying elements in the form of a powder suspended in a liquid, optionally mixed with a binder. In case the metal sheet 1 is a steel sheet, the alloying element may in particular be carbon. However, nitrogen, manganese, silicon, chromium or nickel are also conceivable. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com