Dumping device

A technology of dumping device and sliding installation, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, to achieve the effects of saving manpower, easy control of the dumping volume, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

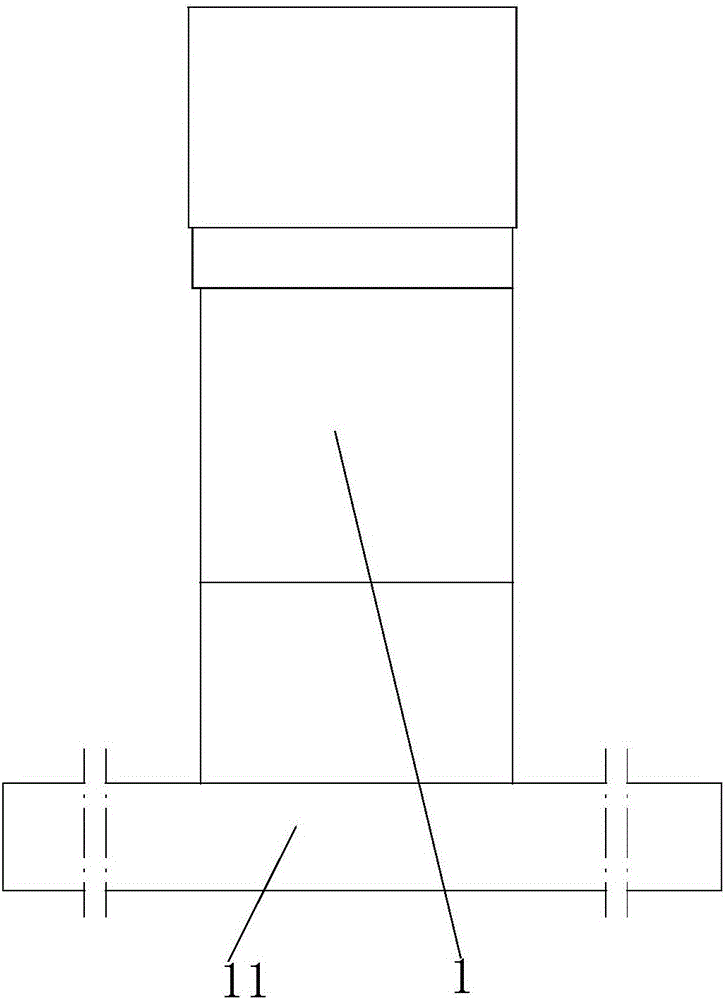

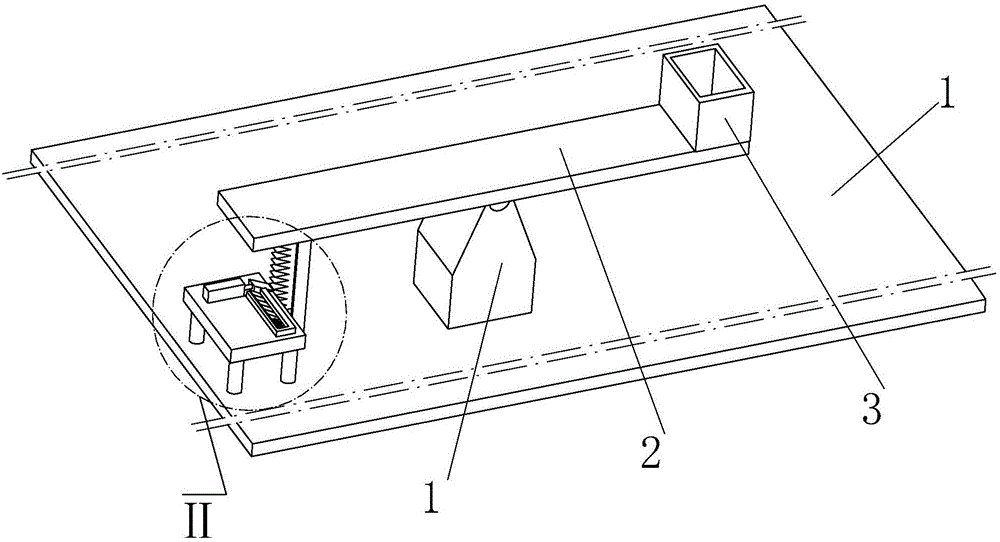

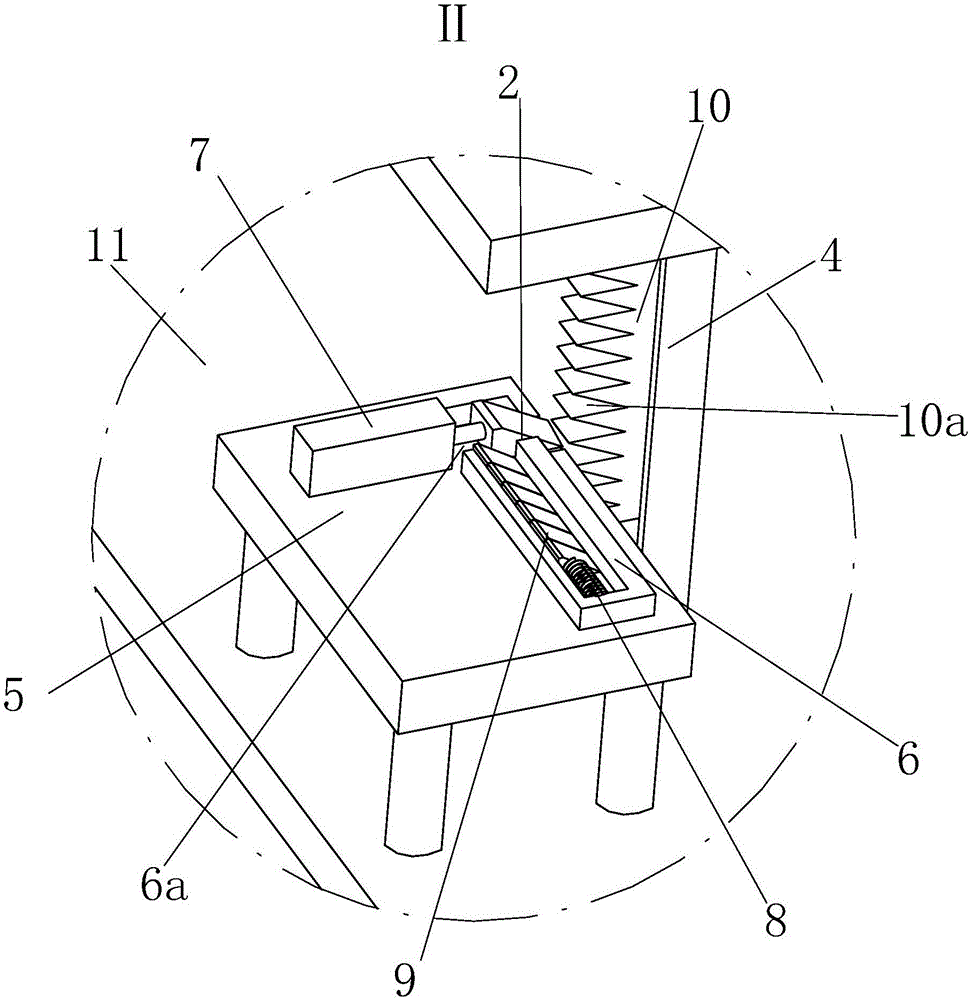

[0018] Such as Figure 1 to Figure 4 As shown, a dumping device includes a general base 11, a top frame 1 is fixedly mounted on the general base 11, a seesaw 2 is hinged on the upper end of the top frame 1, and a storage Box 3, the rear lower end of the seesaw 2 is abutted with a rising push block 10, and the overall base 11 is welded with a guide rail frame 4 that slides and installs the rising push block 10 along the vertical direction, and the rising push block Right triangle calipers 10a are evenly distributed on the rear end face of 10;

[0019] The rear of described rising push block 10 is provided with the pad platform 5 that is fixedly installed on the general base 11, and described pad platform 5 is provided with storage tank rack 6, and the left front end of described tank ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com