Structured cementitious granular material and method for its preparation

A technology for cementing particles and cementing materials, which is used in infrastructure engineering, construction, soil protection, etc., and can solve the problem of failure to form integral mechanical properties, loss of soil consolidation drainage channels around gravel piles, and inability to control the compaction of cemented bodies. To achieve the effect of less environmental pollution, improved strength, and less engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the structured cementitious granular material 100 according to the embodiment of the present invention includes the following steps:

[0040] S1: Carry out tests according to the cementing type of the cementing granular material 2 required by the design to determine the fluidity and viscosity of the self-compacting cement-based cementing material 3;

[0041] S2: accumulation of granular material 1;

[0042] S3: Determine the cemented area of the granular material 1 and the grouting amount of the self-compacting cement-based cementitious material 3 required to form the cemented granular material 2;

[0043] S4: filling the cementing area with self-compacting cement-based cementing material 3 , the self-compacting cement-based cementing material 3 binds the granular material 1 on the flow path into cemented granular material 2 . It is to be understood that, in the structured cementitious granular material 100 prepared by the preparation method...

Embodiment 1

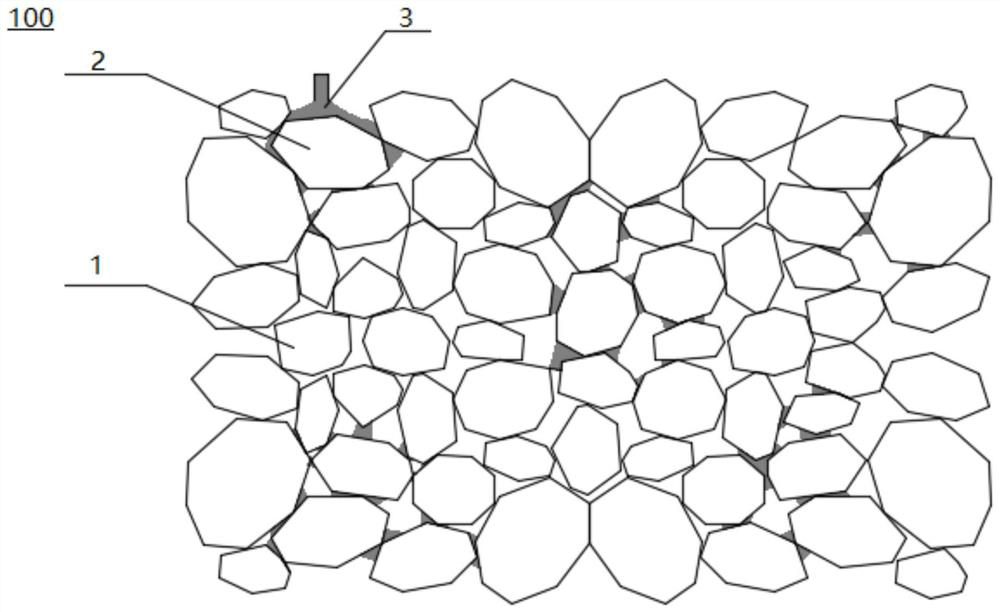

[0051] Embodiment 1: as figure 1 As shown, the construction result of this embodiment is a contact-type structured cemented granular material 100, which can be applied to gravel pile reinforcement projects, and the structured cemented technology can be applied to rockfill dams, slopes and foundations, etc. Reinforcement project, the particle size of granular material is 0.01m-0.1m crushed stone, self-compacting cement-based cement material 3 adopts self-compacting cement paste, the expansion degree of self-compacting cement paste is 290mm, V funnel value is 1.9s, pouring The formed cemented granular material 2 only forms cementation in the local area of the particle contact point, and the cemented granular material maintains the original grain skeleton structure and pore structure of the granular material, and has high water permeability.

[0052] Concrete preparation steps are as follows:

[0053] S1: Conduct tests according to the design requirements to determine that the...

Embodiment 2

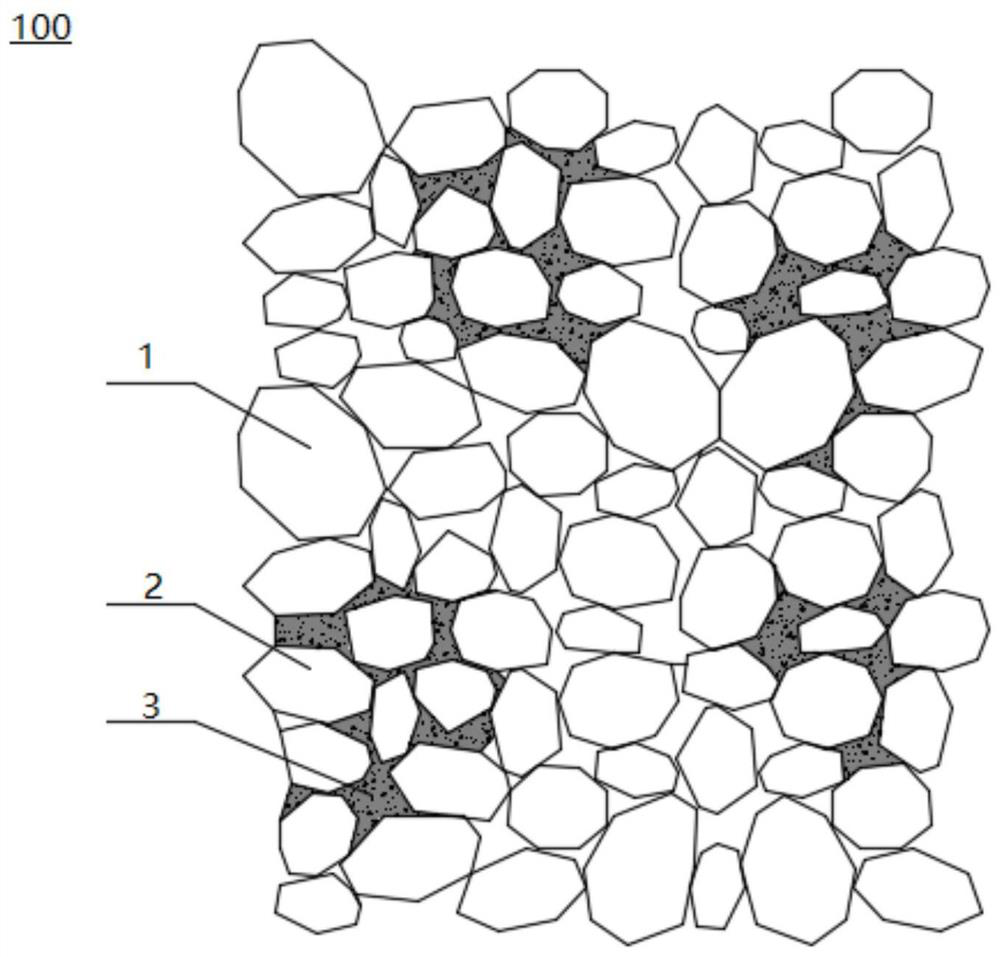

[0057] Embodiment 2: as figure 2 As shown, the construction result of this embodiment is a dense structured cemented granular material 100, which can be applied to rockfill seawall projects, and the particle size of the granular material is 0.3m-1m rockfill , the self-compacting cement-based cementing material 3 adopts self-compacting concrete, the expansion degree of self-compacting concrete is 680 mm, the slump is 260 mm, and the V funnel value is 12 s. The size of the cemented granular material 2 is 3m-5m. A single cemented granular material 2 has the performance of a concrete block, and multiple cemented granular materials 2 form a structured cemented granular material 100 with surrounding rockfill materials.

[0058] Concrete preparation steps are as follows:

[0059] S1: Carry out tests according to the design requirements to determine that the self-compacting concrete that forms the dense cemented granular material 2 has a degree of expansion of 680mm, a slump of 260m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com