Automatic tray arranging machine and work method thereof

A kind of swinging machine and automatic technology, which is applied in the direction of conveyor objects, destacking, transportation and packaging of objects, can solve the problems of high labor intensity, low work efficiency and increase production costs, so as to reduce production costs and save manpower. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

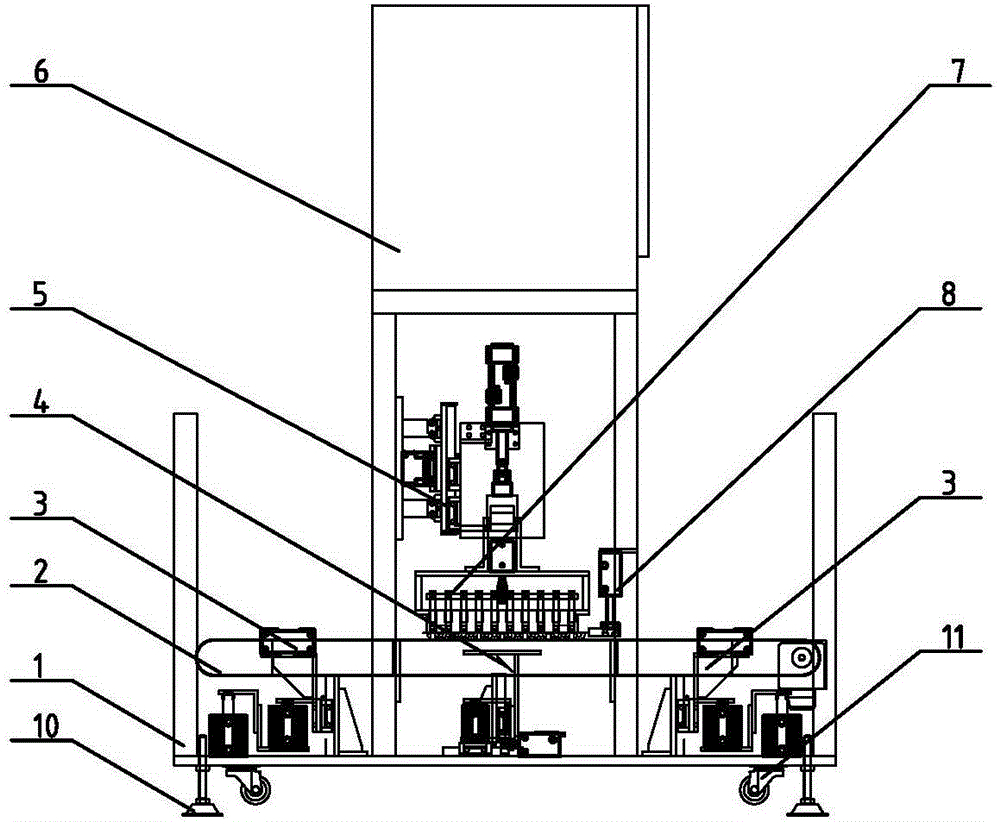

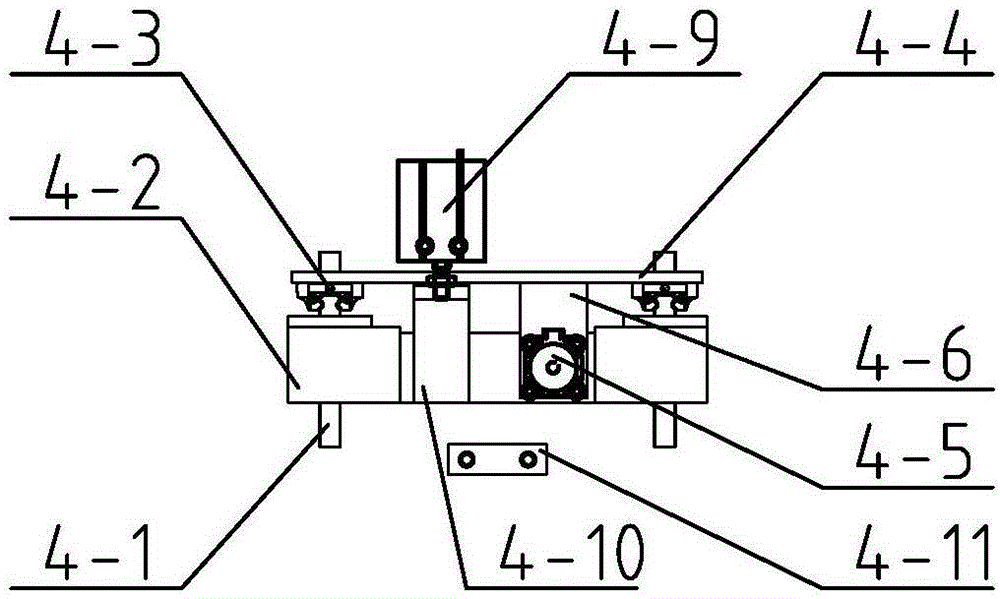

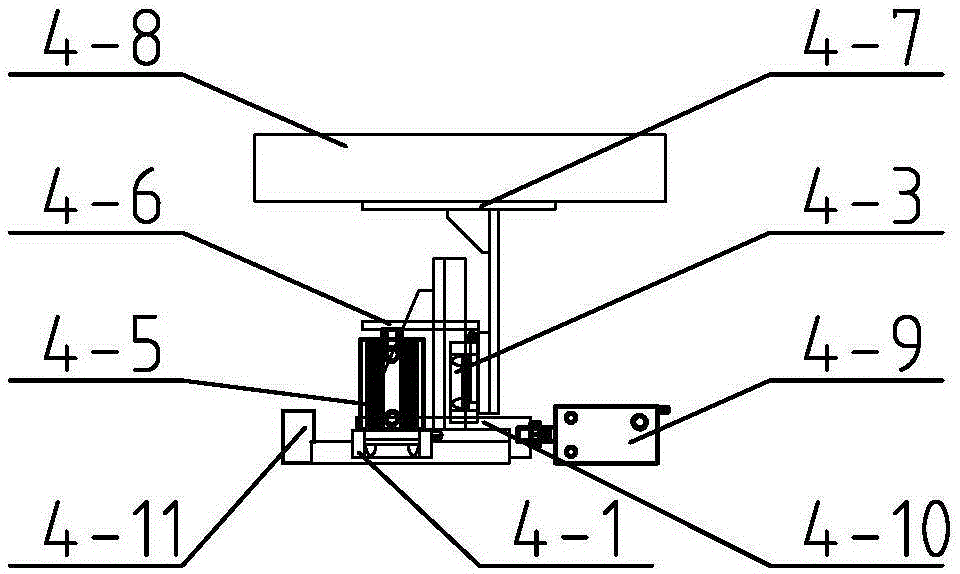

[0032] Embodiment, with reference to accompanying drawing, a kind of automatic plate-setting machine, comprises main frame body-1, electric control system 6 is housed on main frame body-1, and conveyor belt 2 is housed in the middle of the lower part of main frame body-1, and its It is characterized in that four tray alignment mechanisms 3 are installed on both sides of the upper part of the conveyor belt 2, and a swing plate movement mechanism 4 is installed in the middle of the lower part of the conveyor belt 2; a grip mechanism 7 is installed on the lower side of the middle part of the conveyor belt 2, The pick-and-place turning mechanism 5 is installed in the middle of the conveyor belt 2 and above the handle mechanism 7;

[0033] Described tray alignment mechanism 3 (see attached Figure 6 , 7 , 8): include upper and lower guide rails 3-2 on the upper and lower brackets 3-1, upper and lower slide seats 3-3 between the upper and lower supports 3-1; cylinder supports are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com