Shifting tool of assembling machine

A machine and tool technology, applied in the field of displacement of assembly and splicing tools, to achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

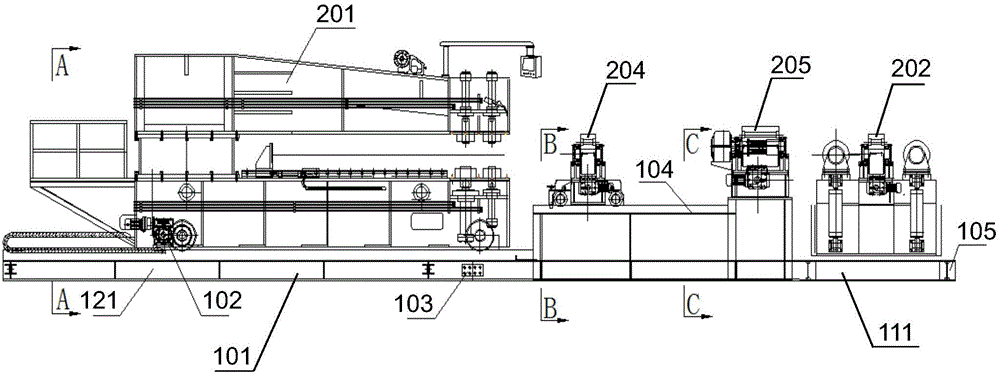

[0017] The invention discloses a displacement tool for a pairing machine, comprising: a base of a pairing machine, a base of a roller group and a base of a walking roller frame. The group-to-machine base carries the group-to-machine. The roller group base carries one or more of the split roller group, the transition roller frame and the hydraulic control station, and the roller group base is connected to the paired machine base. The walking roller frame base carries the walking roller frame.

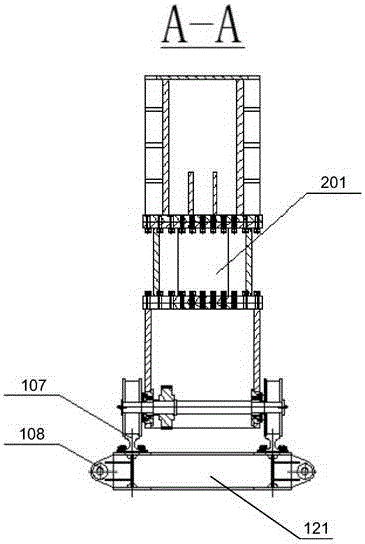

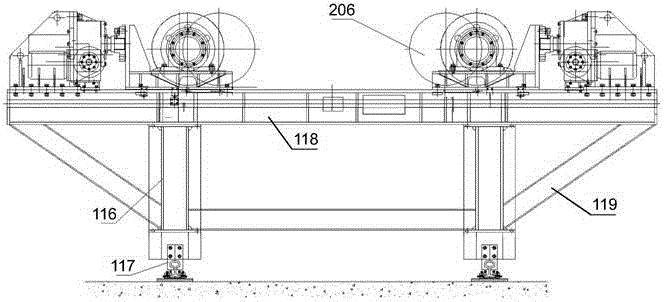

[0018] refer to Figure 1a , Figure 1b , Figure 2a , Figure 2b and Figure 2c , Figure 1a Disclosed is a side structural view of the assembly machine base and the roller set base in the assembly machine shifting tool according to an embodiment of the present invention. Figure 1b Disclosed is a top structural view of the assembly machine base and the roller set base in the assembly machine shifting tool according to an embodiment of the present invention. Figure 2a , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com