Shift control mechanism of steering-wheel tractor

A control mechanism and tractor technology, applied in the field of tractors, can solve the problems of insufficient movement range of connecting rods and fixed bushings, easy to wear ball-end curved rod sections, inaccurate shifting, etc., and achieve small clearance and accurate gear shifting. , the effect of flexible shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

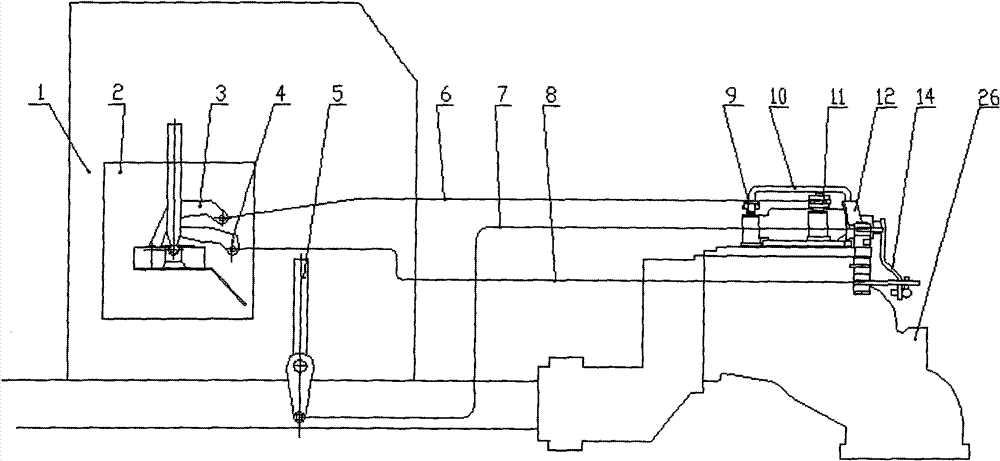

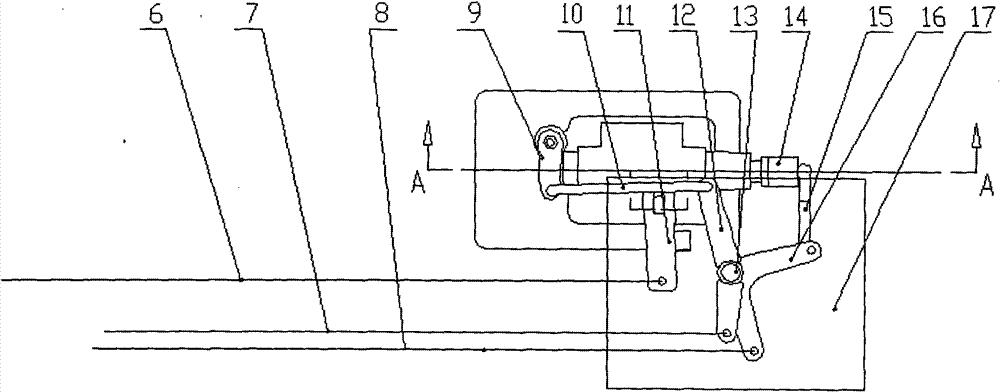

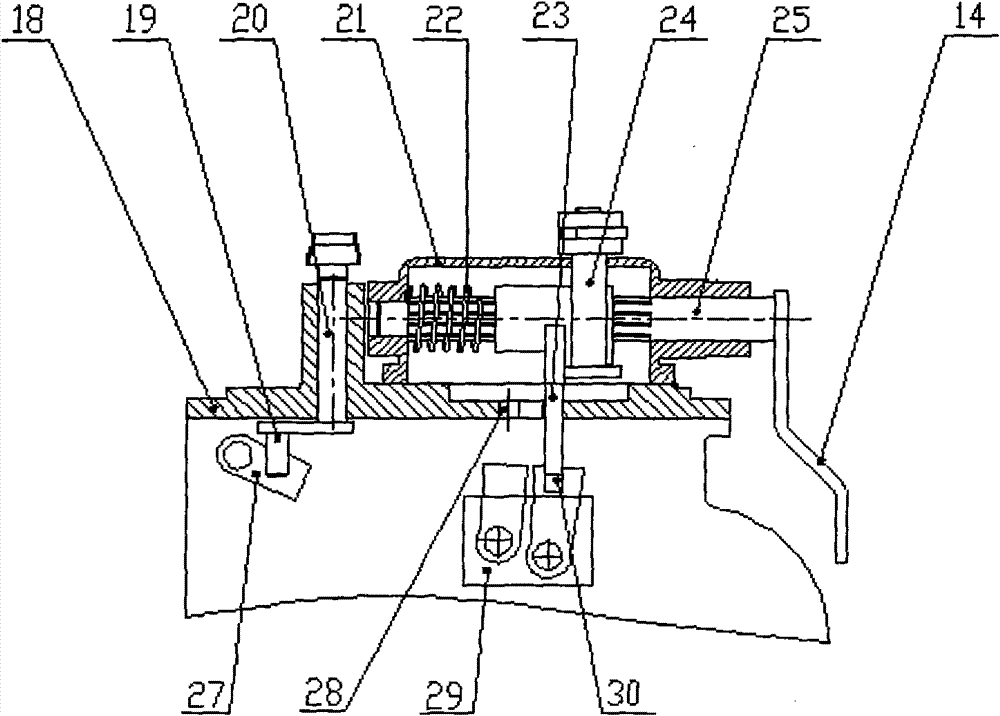

[0023] See attached Figure 1~5 As shown, the steering wheel type tractor gear shifting mechanism of the present invention adopts a soft axis to realize manipulation and shifting, and includes a shifting transmission assembly and a shifting manipulation assembly, wherein the shifting transmission assembly consists of a gearbox lower cover 18, a gearbox top cover 21 and The transmission intermediate assembly 17 is formed. The front part of the gearbox lower cover 18 is provided with a "work"-shaped gear limit hole 28, and the rear part is equipped with an auxiliary transmission shaft 20. The upper end of the auxiliary transmission shaft 20 is equipped with a rocker arm 9, and the lower end has a right-angle The rotating arm 19 and the right-angle rotating arm 19 extend into the groove of the auxiliary transmission shift fork 27, and the transmission top cover 21 is installed on the top of the "work" shape gear limit hole 28 of the transmission lower cover 18, and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com