Gear-shifting mechanism of harvester

A technology of shifting mechanism and harvester, which is applied to harvesters, agricultural machinery, implements, mechanical equipment, etc., can solve problems such as hidden dangers in operating harvesters, insufficient rigidity of control levers, and difficulty in entering the gear levers. The effect of convenient layout, simple structure and light structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

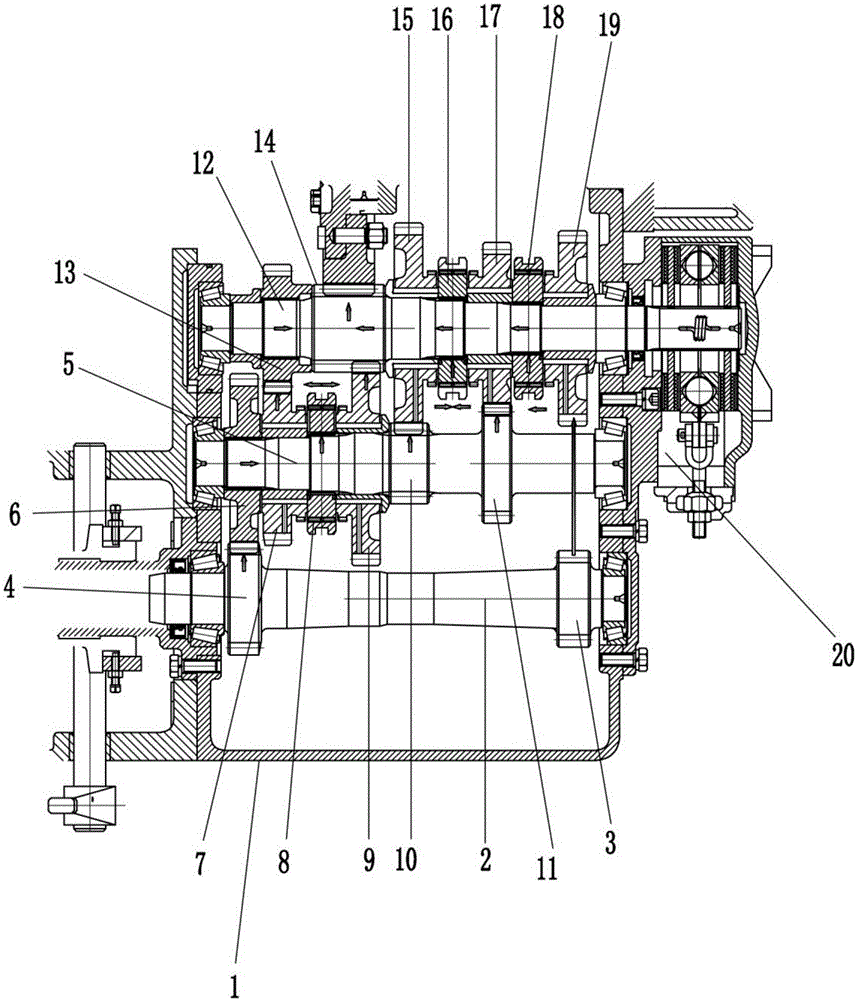

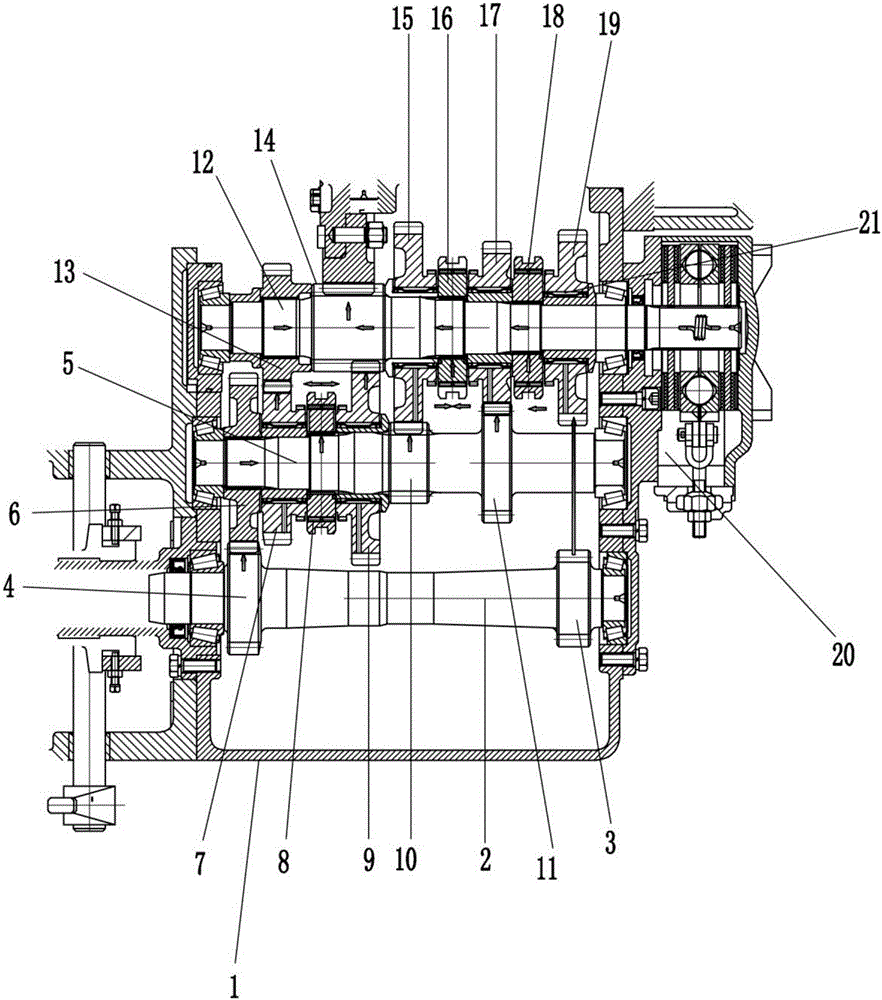

[0022] A harvester shift mechanism, such as Figure 1-2 As shown, it includes a main box 1, a first rotating shaft 2, a first gear 3, a second gear 4, a second rotating shaft 5, a primary reduction driven gear 6, a third gear driving gear 7, a third and fourth gear hub ring 8, Fourth gear driving gear 9, third gear 10, fourth gear 11, third shaft 12, third gear driven gear 13, fifth gear 14, first gear driven gear 15, first and second gear hub ring 16, second gear driven gear 17. Reverse gear hub ring 18, reverse gear driven gear 19 and handbrake mechanism 20, the main box 1 is provided with a first rotating shaft 2, a second rotating shaft 5 and a third rotating shaft 12, and the first rotating shaft 2 is provided with a first Gear 3 and second gear 4, the second rotating shaft 5 is provided with first-stage reduction passive gear 6, third gear driving gear 7, third and fourth gear hub ring 8, fourth gear driving gear 9, third gear 10 and fourth gear 11. The first-stage redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com