Freeze-resistant type heat exchanger with three-dimensional air cavity

A heat exchanger and shell-and-tube heat exchanger technology is applied in the field of anti-freezing heat exchangers, which can solve the problems of heat exchangers that are not resistant to freezing, affect equipment operation and safety, and volume expansion, and achieve large heat exchange. , to achieve the effect of anti-freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

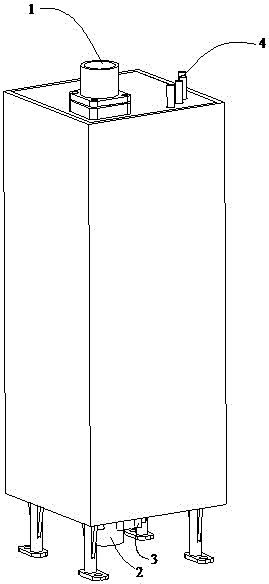

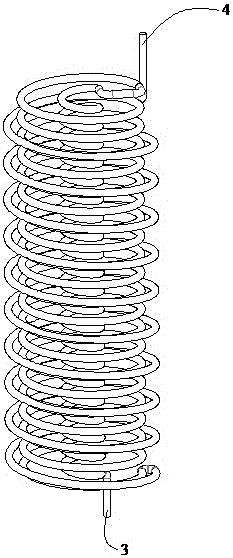

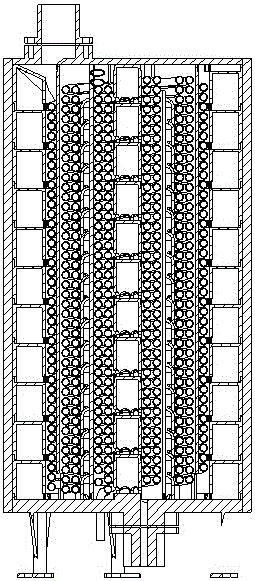

[0020] refer to Figure 1 to Figure 7 , the invention discloses an anti-freezing heat exchanger with a three-dimensional air cavity, which is a shell-and-tube heat exchanger with metal tubes built in, and multi-channel parallel metal tubes are coiled in the shell to be connected to each other and formed by a large To a plurality of small concentric rings, the sleeves are used to isolate the adjacent rings, and it also has a brine outlet 1, a brine inlet 2, a liquid refrigerant outlet 3, and a gaseous refrigerant inlet 4.

[0021] The sleeve used to isolate the metal pipe can be made of a plurality of cups with a circular air cavity, or it can be made of an open cylinder as the base surface, and a series of rings that shrink at one end are sleeved , forming a series of air cavities, or superimposed special air cavities made by using the local gaps of the shell.

[0022] As a preferred air cavity, its top must be sealed, and its lower end cavity is open or has a gap or a hole t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com