A kind of permeable brick and preparation method thereof

A technology of permeable bricks and brick bodies, which is applied to ceramic products, other household appliances, and pavements paved with prefabricated blocks, etc. It can solve the problems of high resource consumption, difficult formula design, and difficulty in meeting the performance requirements of permeable bricks, etc., and achieve reduction Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing the permeable brick described in the above technical solution, comprising the following steps:

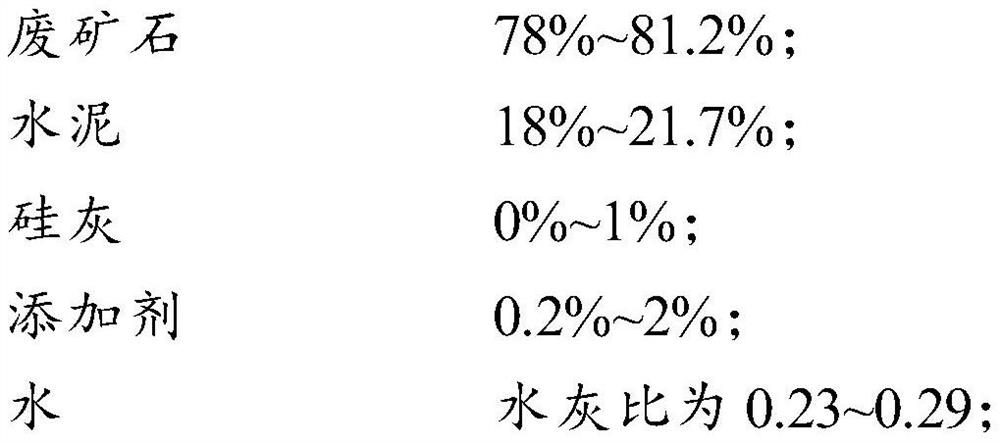

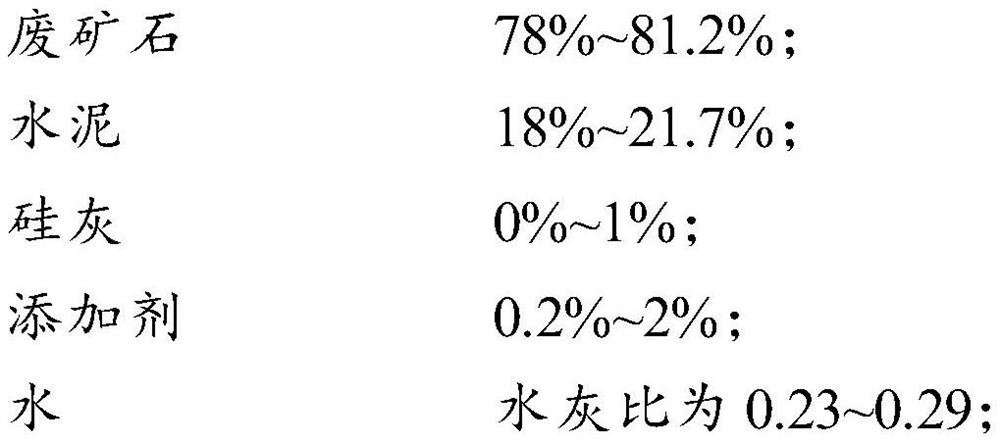

[0064] a) mixing waste ore, cement, silica fume, additives and water to obtain surface layer slurry;

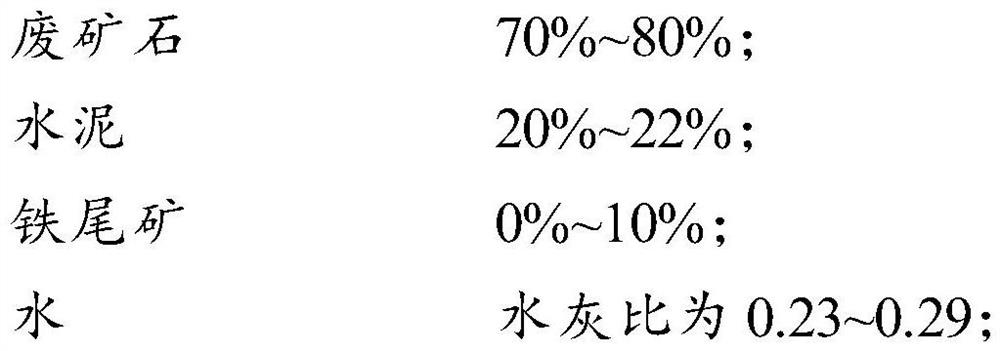

[0065] b) mixing waste ore, cement, iron tailings and water to obtain bottom layer slurry;

[0066] c) After distributing the bottom slurry, carry out initial pressure;

[0067] d) distributing the surface layer slurry on the bottom layer slurry after the initial pressure, and performing vibratory hydraulic pressure to obtain a permeable brick;

[0068] The steps a) and b) are not limited in sequence.

[0069] Wherein, the types and dosages of the waste ore, cement, silica fume, additives, iron tailings and water are consistent with those described in the above technical solution, and will not be repeated here.

[0070] Regarding step a): the mixing process is preferably as follows: firstly, the waste ore is stir...

Embodiment 1

[0081] S1. Add 80% of iron ore waste rock aggregate (5-10mm) and 20% of cement a into a forced mixer, and dry mix for 1 minute; then add water and stir (the water-cement ratio is 0.28) for 8 minutes to obtain the bottom layer slurry material.

[0082] S2. Add 80% of the iron ore waste rock aggregate (1-3mm) into the mixer, add additional water (0.10% of the aggregate) to fully stir and moisten; then add 19.7% of cement a, 0.3% of dyeing agent, and then add water Stir (the amount of water added is 0.26 according to the water-cement ratio) for 4 minutes to obtain the surface layer slurry.

[0083] S3. First arrange the bottom material for initial pressing, then lay out the fabric, and at the same time carry out vibratory hydraulic pressure for 8s to obtain permeable bricks.

[0084] Among them, the mass ratio of the surface layer slurry to the bottom layer slurry is 0.5:6, the cloth thickness of the bottom material is 90mm, and the initial pressure is 50kn; the cloth thickness ...

Embodiment 2

[0086] S1. Add iron ore waste rock aggregate (3-5mm) 34%, (5-10mm) 45%, cement a 21%, add to the forced mixer, dry mix for 1min; then add water and stir (the amount of water added is based on the water-cement ratio Be 0.28) 4min, obtain bottom layer slurry.

[0087] S2. Add 81.2% of iron ore waste rock aggregate (1-3mm) into the mixer, add additional water (accounting for 0.10% of the aggregate) to fully stir and moisten; then add cement a18%, dyeing agent 0.3%, add water and stir (The amount of water added is 0.26 according to the water-cement ratio) for 6 minutes to obtain the surface layer slurry.

[0088] S3. First arrange the bottom material for initial pressing, then lay out the fabric, and at the same time carry out vibratory hydraulic pressure for 8s to obtain permeable bricks.

[0089] Among them, the mass ratio of the surface layer slurry to the bottom layer slurry is 0.5:6, the cloth thickness of the bottom material is 45mm, and the initial pressure is 50kn; the cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com