Anti-damage wiring outlet device

An export device and anti-folding technology, applied in the direction of electrical components, etc., can solve the problems of staying in the model stage and difficult to realize, and achieve the effect of reducing fatigue, convenient use, and improving the technical level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

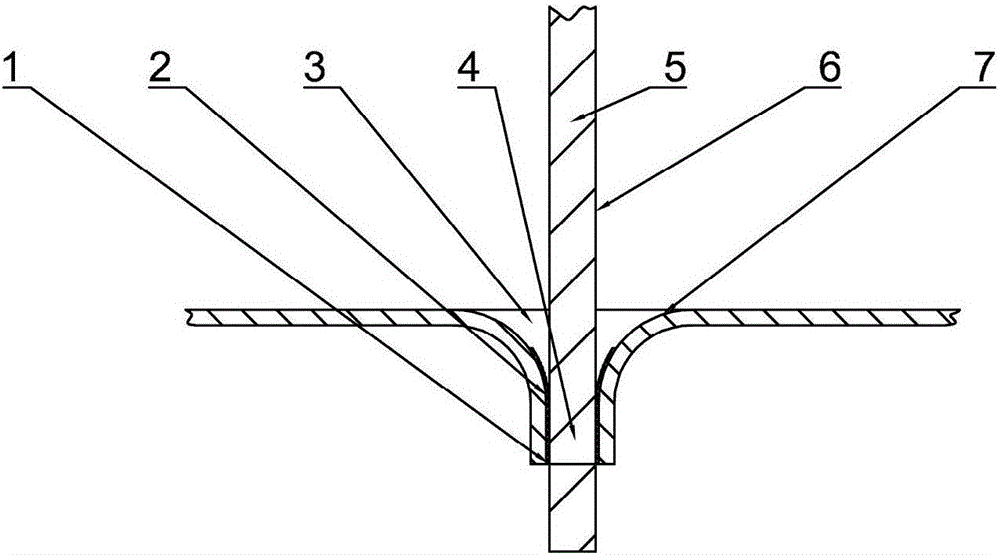

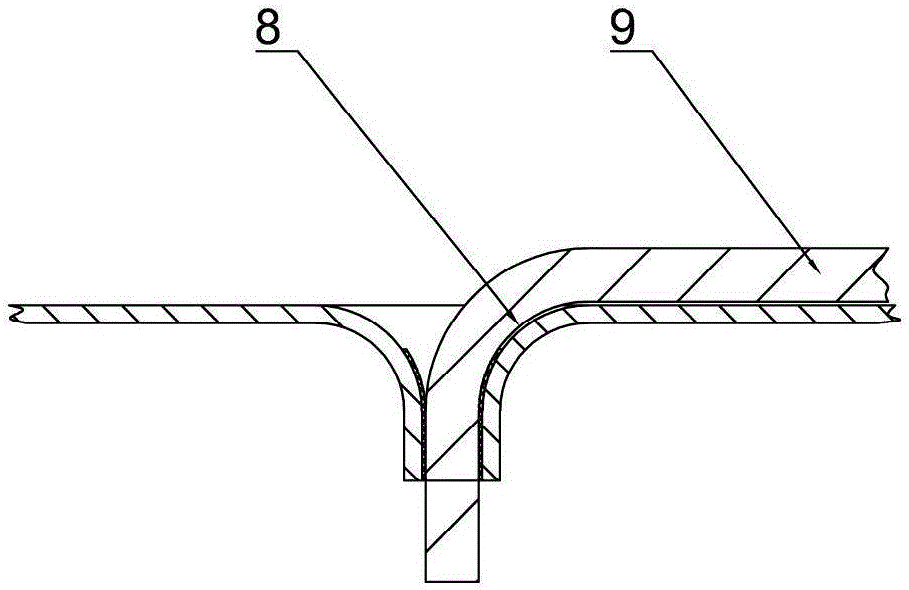

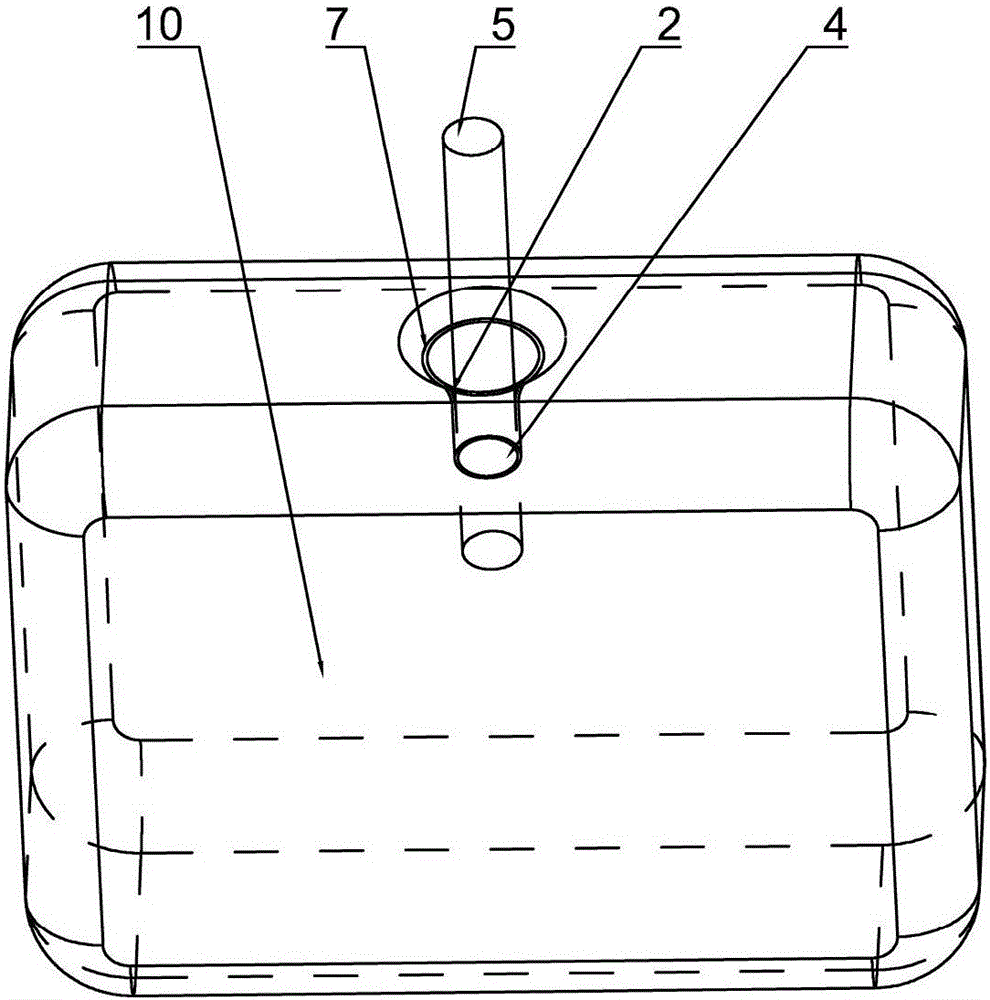

[0020] see Figure 1~3 , the embodiment of the present invention is funnel-shaped, and is provided with device internal angle 1, device bottom through hole 4, electric wire and cable 5, device male angle 7; Described device female angle 1 is a right angle, and described device male angle 7 is a rounded corner, The fillet radius of the male corner 7 of the device is at least twice the diameter of the wire and cable 5; the through hole 4 at the bottom of the device is connected to the wire and cable 5 with clearance fit, and a flexible protection is provided between the through hole 4 at the bottom of the device and the wire and cable 5 Layer 2. exist figure 1 In , mark 6 is the upright position of the cable; in figure 2 , mark 8 is the minimum bending radius of the maximum bending position of the cable, and 9 is the maximum bending position of the cable; in imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com