Grain airing device

A technology of raking and raking teeth is applied in the field of grain drying machines, which can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing manual operation and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

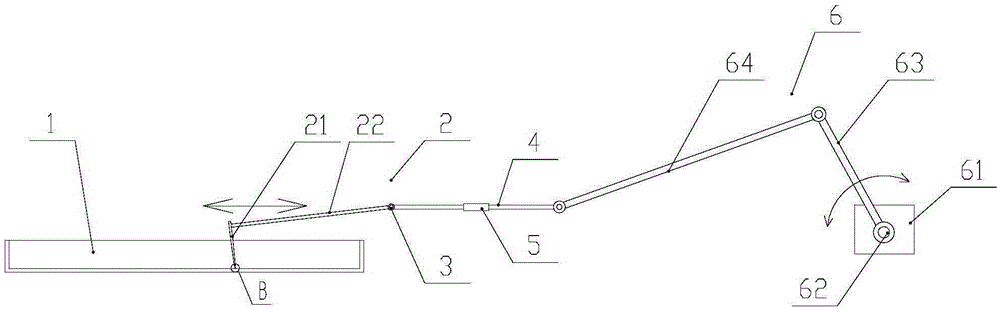

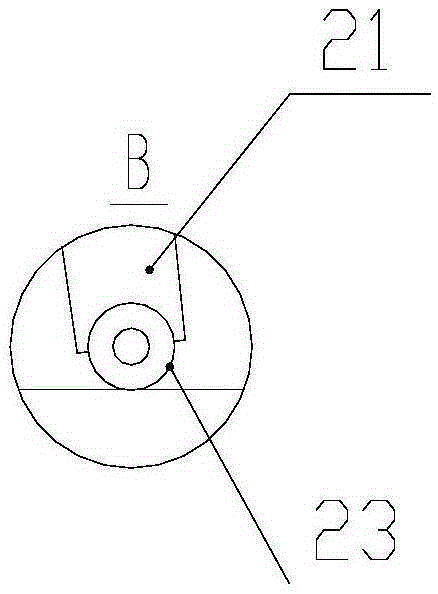

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the grain drying device of this embodiment includes a grain drying trough 1 and a grain drying rake 2, and the grain drying rake 2 includes rake teeth 21 and a rake handle 22, and the grain drying rake The rake teeth 21 of 2 are in the grain drying trough 1, and the rake handle 22 of the grain drying rake 2 is hinged on the connecting arm 4 through the horizontal pivot 3, and the connecting arm 4 is driven to reciprocate horizontally in the chute 5 by the transmission mechanism 6 . The grain drying harrow 2 reciprocates with the connecting arm 4, and the grains in the grain drying trough 1 are raked and plowed by the rake tines 21, without manual raking and plowing, and the efficiency is high. The rake handle 22 is hinged on the connecting arm 4 so that the grain drying rake 2 can freely and flexibly make the rake teeth 21 contact with the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com