Cereal airing machine

A grain and reciprocating mechanism technology, applied in agricultural machinery and implements, botanical equipment and methods, fruit suspension devices, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing manual operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

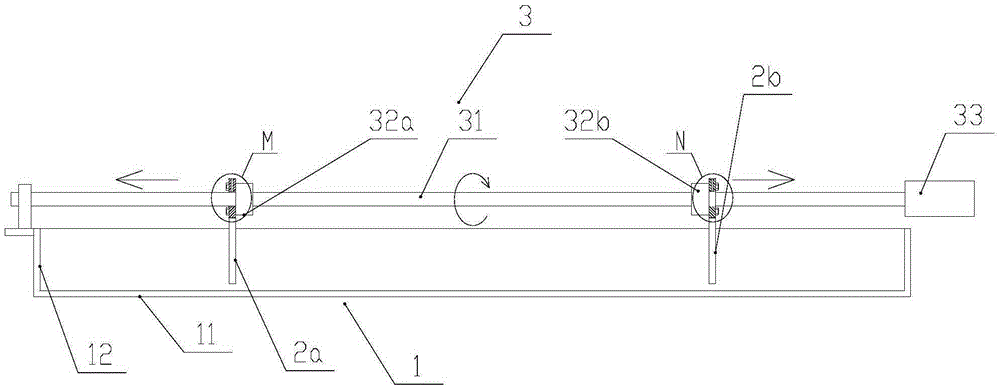

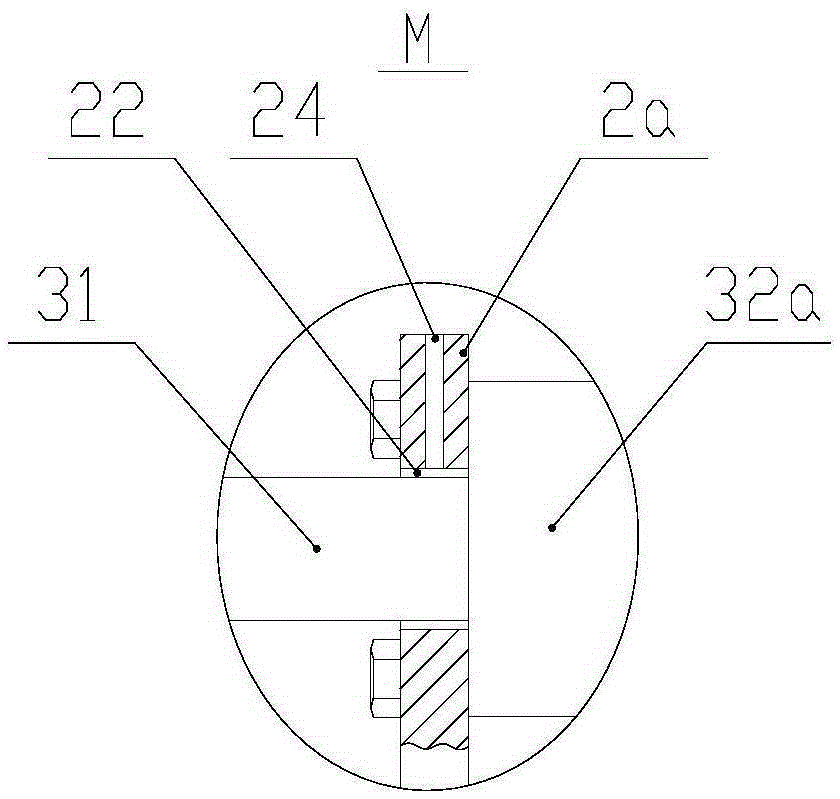

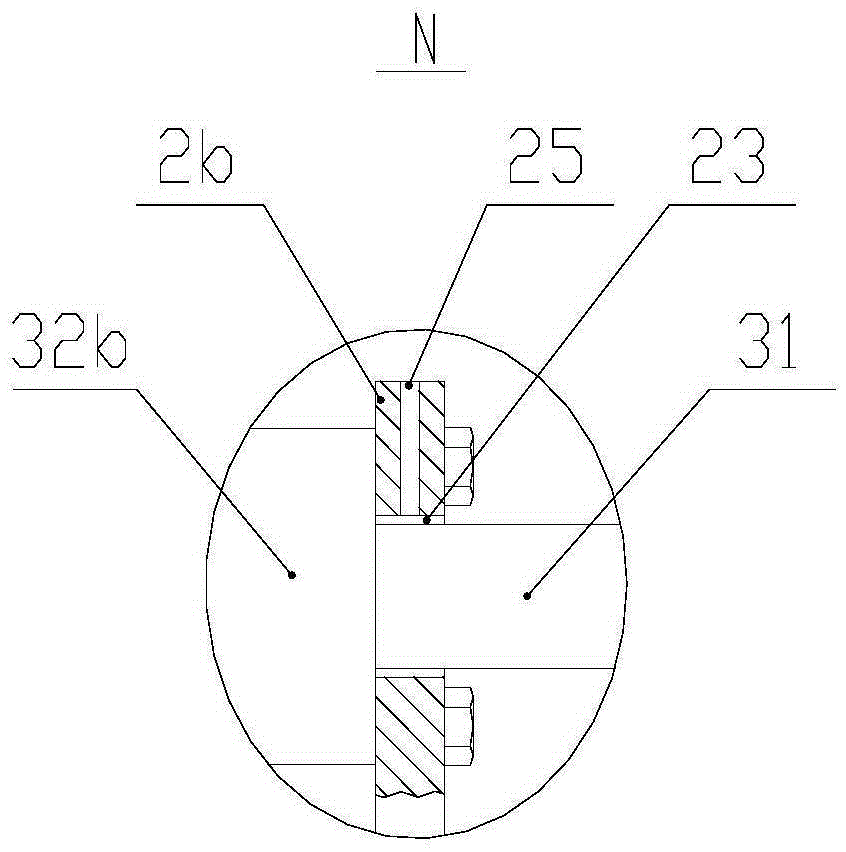

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the grain drying machine of the present embodiment includes a drying tank 1, and the drying tank 1 is composed of a tank bottom 11 and a tank wall 12 extending upwards around the tank bottom 11, The drying tank 1 is provided with a pusher plate, which is at a certain distance from the bottom 11 of the tank. The pusher plate has a number of gaps from the bottom surface to form rake teeth. The pusher plate is driven by the reciprocating mechanism 3 to reciprocate in the drying tank 1. . The pusher plate reciprocates horizontally under the action of the reciprocating mechanism 3, thereby flattening the grains on the bottom 11 of the drying tank 1, and the grains are plowed by the rake teeth, which reduces manual operations and improves production efficiency.

[0013] As a further improvement of the above-mentioned technical solution, the pusher pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com