Reinforced compact fan-shaped section under heavy pressure of continuous-cast solidification tail end

A technology of solidification end and fan-shaped section, which is applied in the field of continuous casting production, can solve the problems such as uncontrollable rebound deformation of cast slab, and achieve the effect of preventing rebound deformation, avoiding looseness, and increasing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

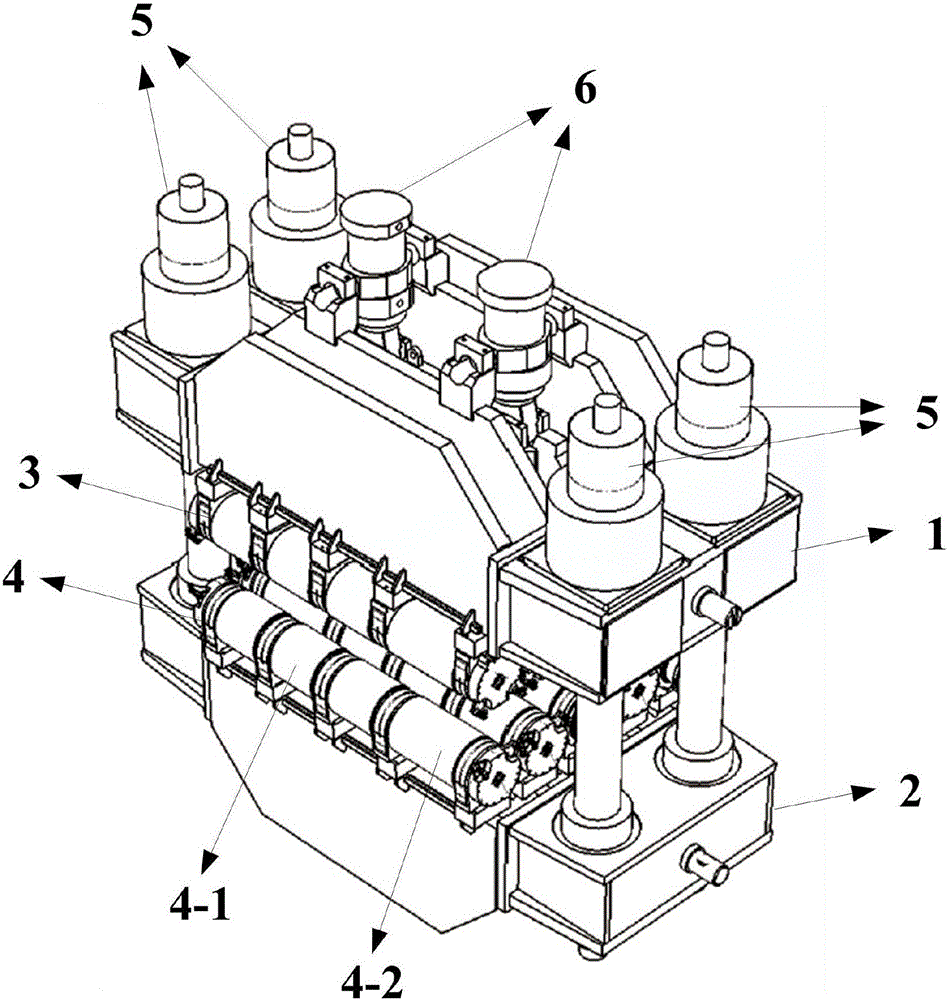

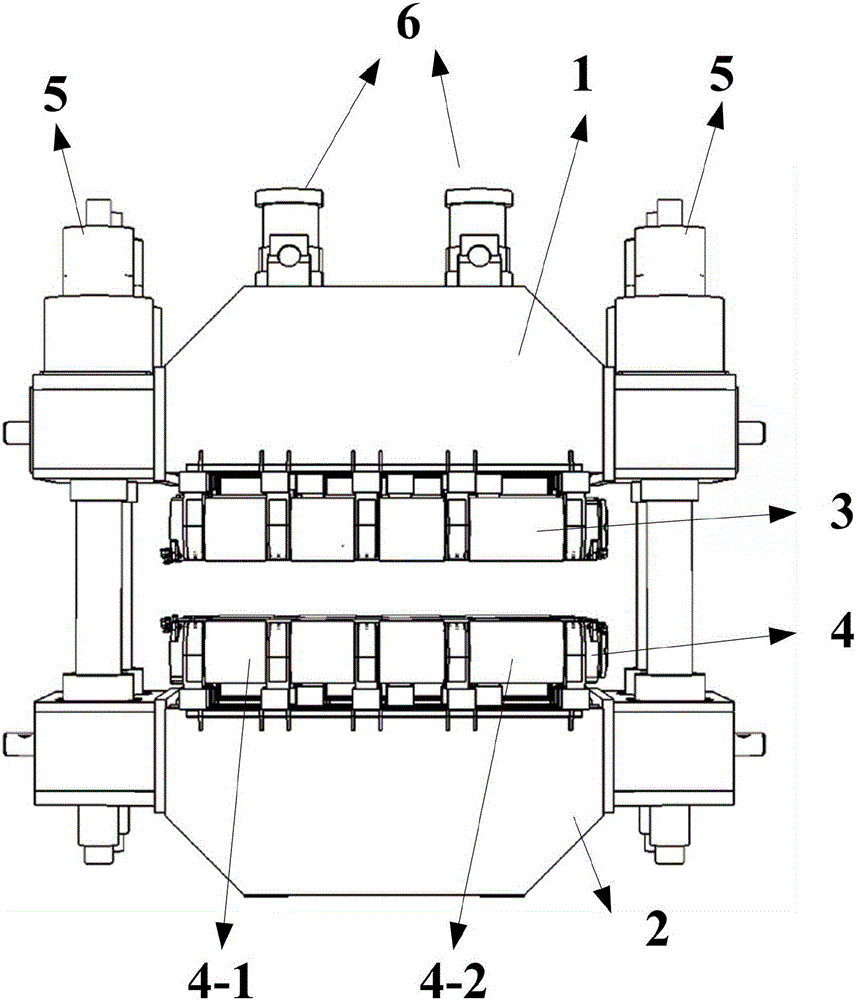

[0026] The invention provides a reinforced compact segment for continuous casting and solidification under heavy pressure, specifically as figure 1 with figure 2 As shown, the fan-shaped section is a horizontal section structure, that is, its roller row is arranged horizontally, including an inner frame 1, an outer frame 2, an inner arc roller row, an outer arc roller row, four clamping cylinders 5 and two Press down the cylinder 6. Wherein, the clamping cylinder 5 is a hydraulic cylinder, which plays the purpose of adjusting the taper of the sector and implementing the process under heavy pressure.

[0027] The inner frame 1 and the outer frame 2 are set up and down oppositely, and the four clamping cylinders 5 pass through the four corners of the inner frame 1 and the outer frame 2 respectively and are fixedly connected with the inner frame 1 and the outer frame 2, and the inner frame 1 and the outer frame of the sector section 2 It has the characteristics of high strengt...

Embodiment 2

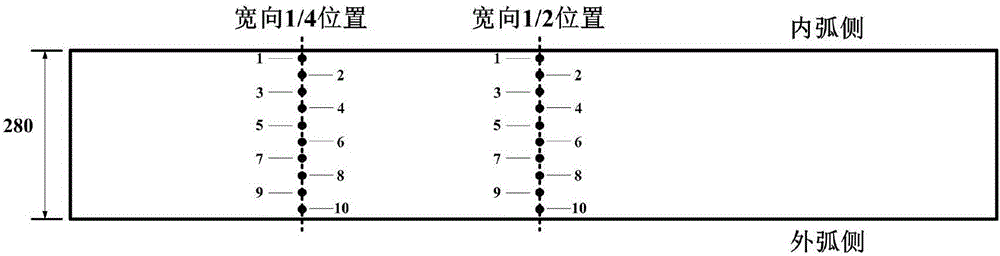

[0038] The cross-sectional size of a wide and thick plate continuous casting machine is 2100mm×280mm, and the horizontal section is composed of 5 compact reinforced fan-shaped sections, namely the 9#-13# section. The segment length is 2.1m, and each segment is composed of 5 pairs of upper and lower rollers. The first upper support roller 3 and the first lower support roller 4 are driving rollers, and the other rollers are driven rollers. The diameter of the driving roller is 390mm. The driving rollers of the inner and outer arc roller rows are equipped with 22kW driving motors at one end, and two pressing cylinders 6 are installed on the driving rollers of the inner arc roller rows. The pressing cylinders 6 are hydraulic cylinders, and the maximum pressure of a single hydraulic cylinder is 1320kN. Four clamping cylinders 5 are installed on the four corners of the inner frame of the segment, and the maximum pressure of a single clamping cylinder 4 is 4750kN. Both the clamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll diameter | aaaaa | aaaaa |

| Roll diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com