A sector-shaped roll row structure for continuous casting solidification end under heavy pressure and its application method

A technology of solidifying the end and segment, which is applied in the field of continuous casting production, can solve the problems of increasing the size and weight of the segment and difficulty in meeting the process requirements, and achieve the effects of increasing the strain rate, improving the density, and preventing rebound deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

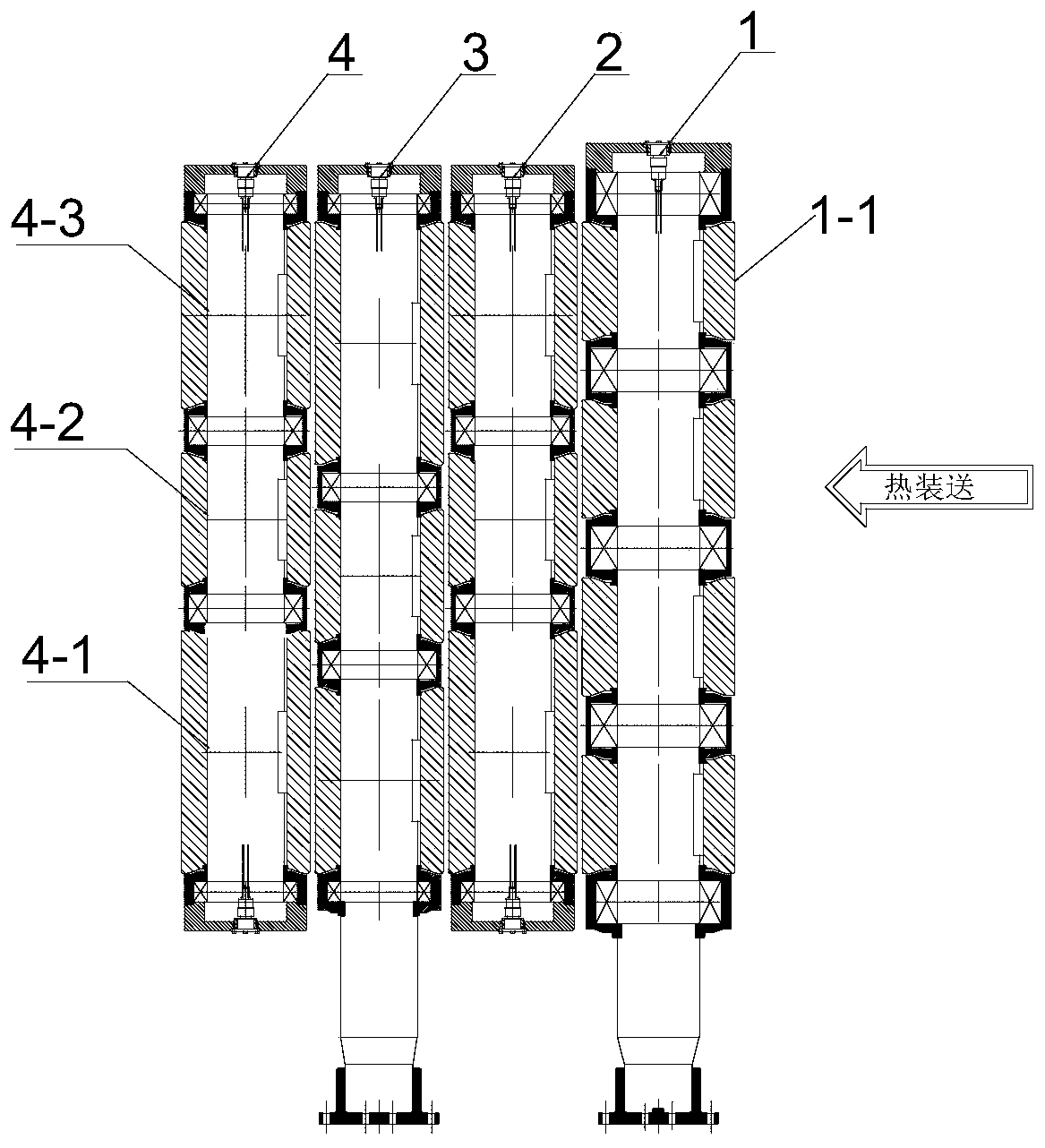

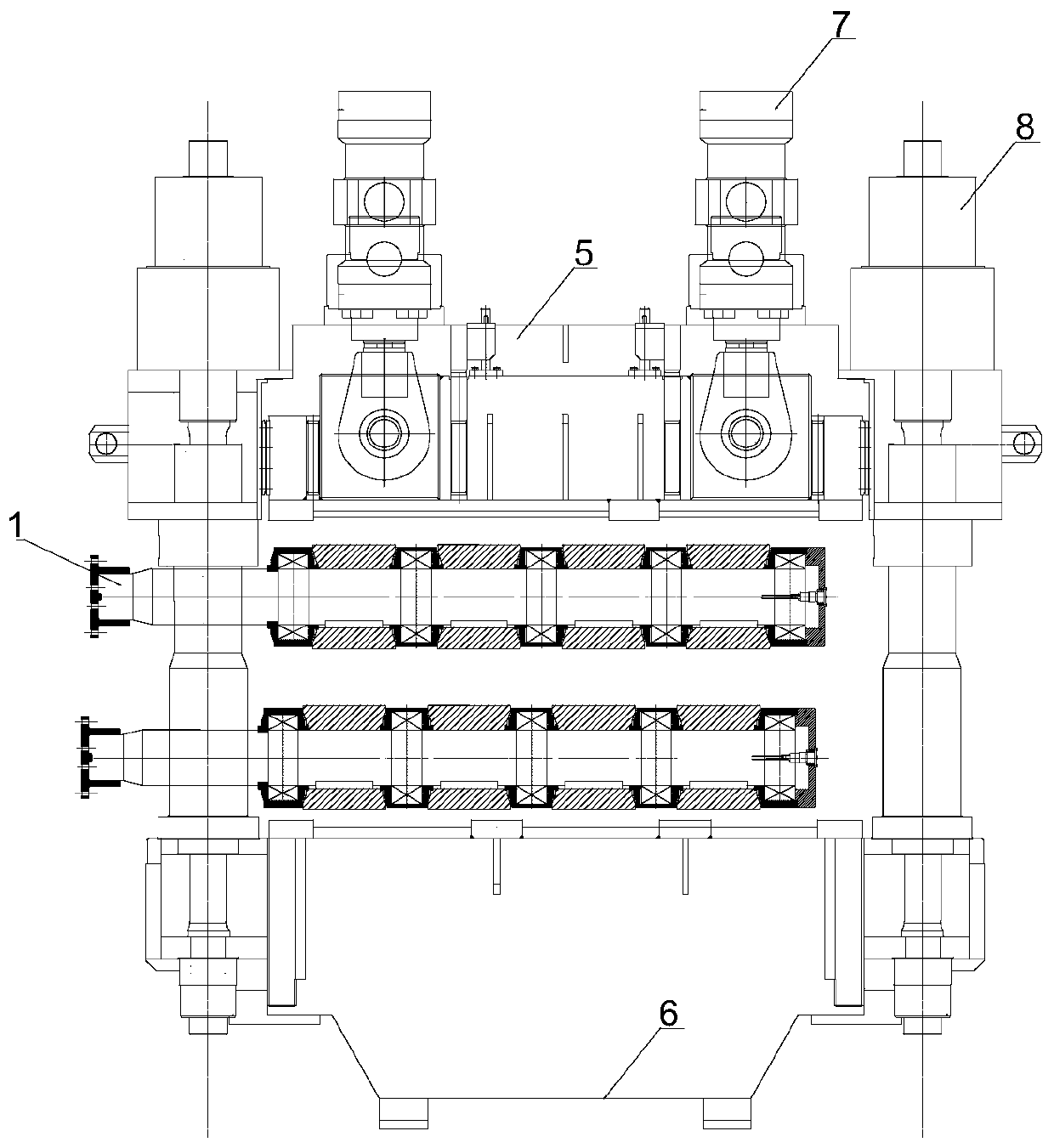

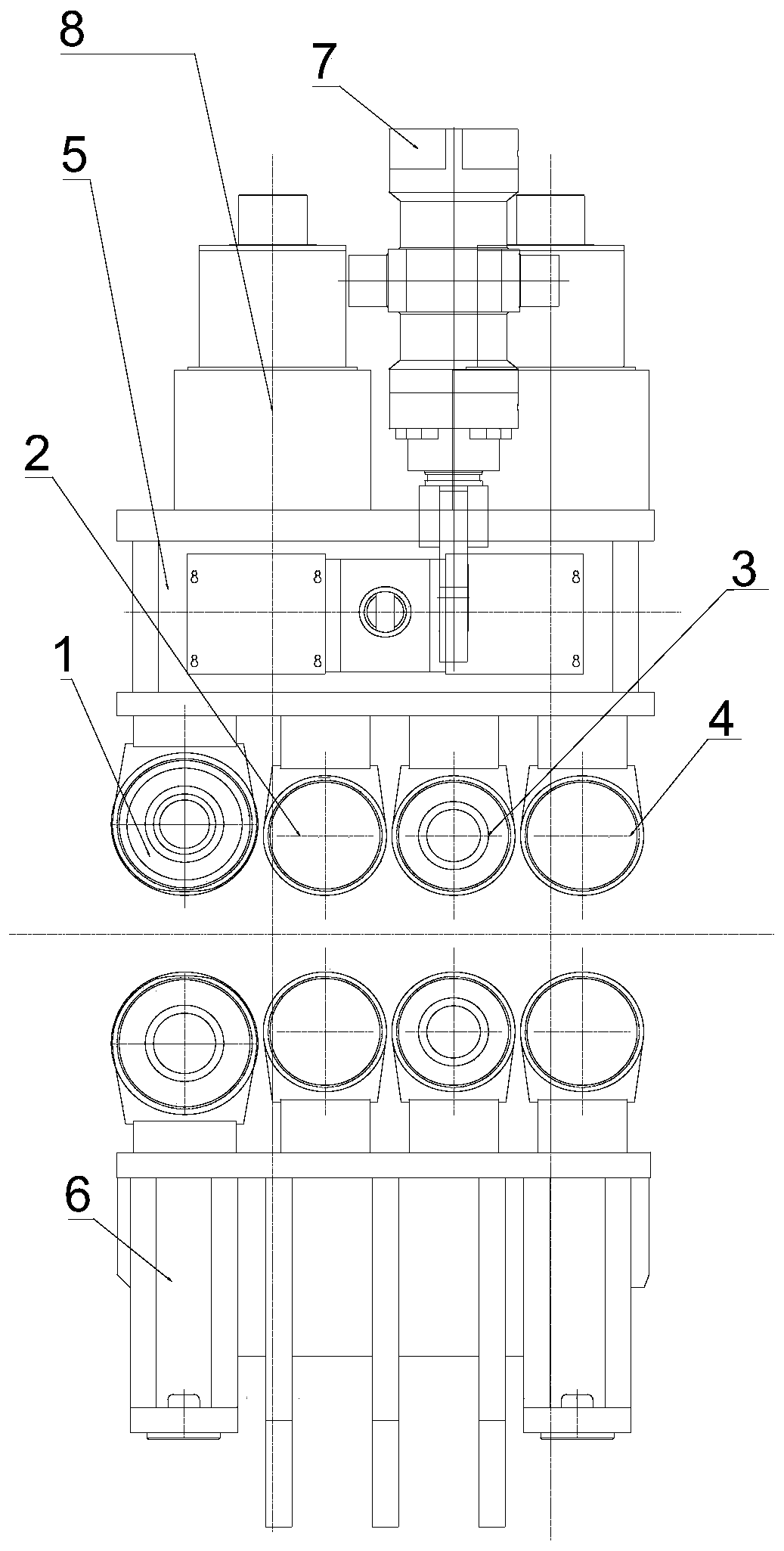

[0027] Such as figure 1 As shown, the present embodiment provides a segmented roller row for heavy pressing at the end of solidification, including four pairs of nip rollers, each pair of nip rollers includes an upper support roller and a lower support roller, and the four pairs of nip rollers are respectively: the first at the entrance A pair of nip rollers 1, and the second pair of nip rollers 2, the third pair of nip rollers 3, and the fourth pair of nip rollers 4 that are arranged in sequence. The first pair of nip rollers 1 is a large-size four-section drive roller, and the second pair of The nip roller 2 and the fourth pair of nip rollers 4 are small-sized three-section driven rollers, and the third pair of nip rollers 3 is a three-section driving roller with the same size as the driven roller.

[0028] Each segmented roller 1-1 of the first pair of nip rollers 1 has the same roll diameter and segment length, and each of the second pair of nip rollers 2 and the fourth pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com