Derusting machine for bearing outer ring of railway vehicle

A technology for bearing outer rings and railway vehicles, which is applied in the direction of grinding racks, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., which can solve the problems that the quality of rust removal cannot be guaranteed, and achieve compact structure, wide application range, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

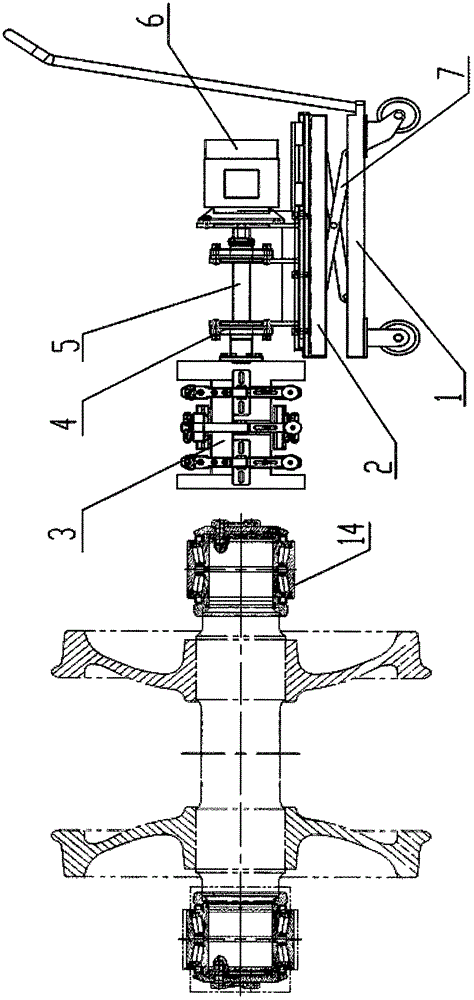

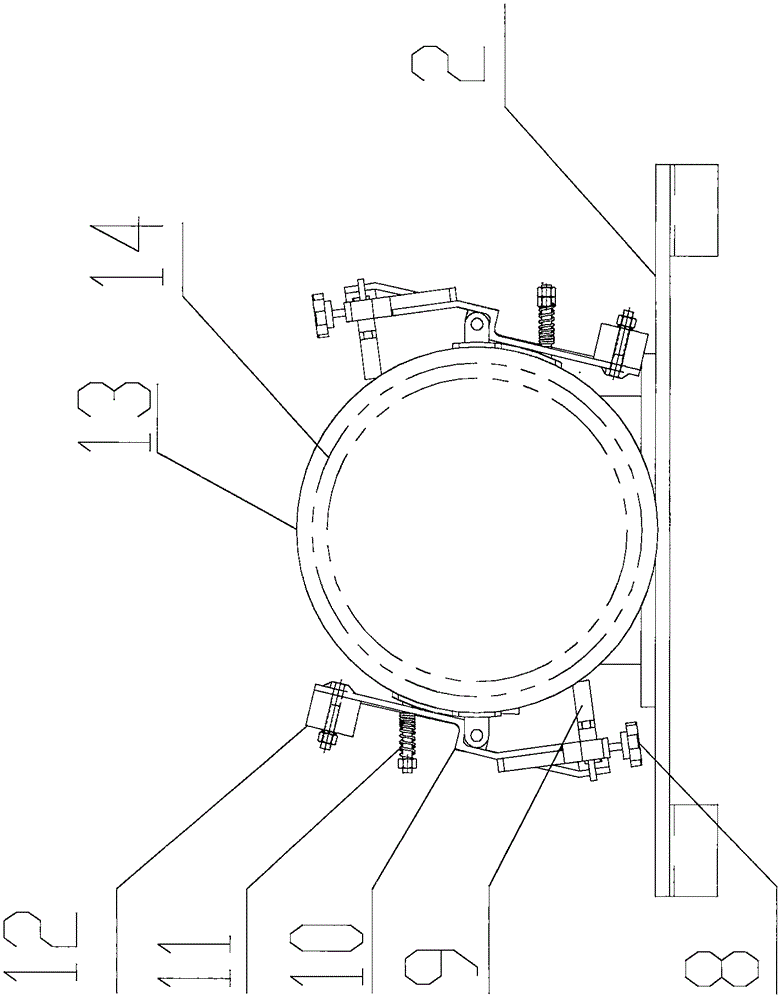

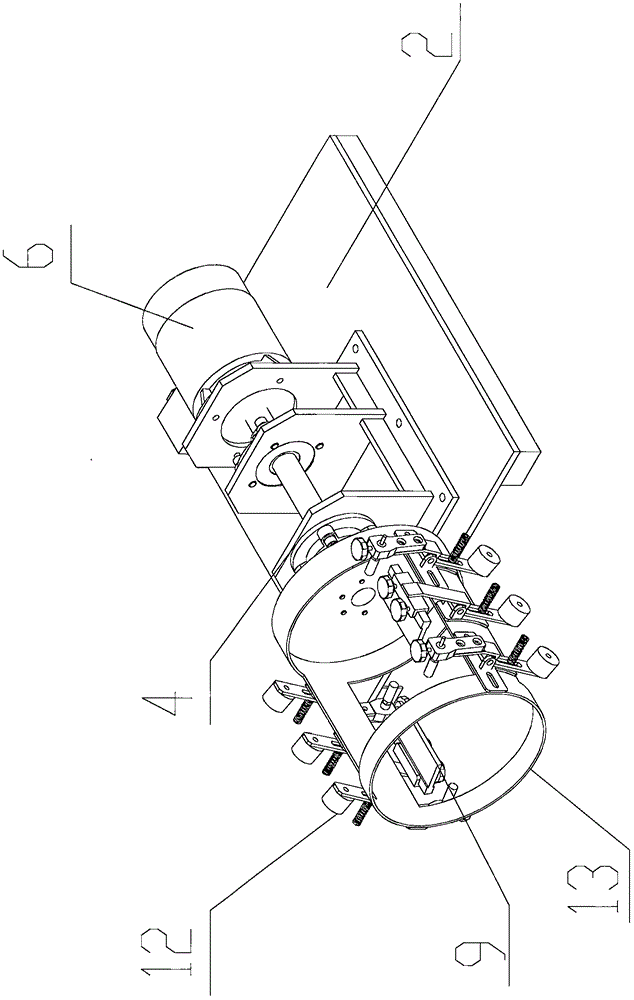

[0017] 1. Please refer to the attached figure 1 , 2 : The complete machine of railway vehicle bearing outer ring derusting machine equipment is made up of trolley (1), height adjustment frame (7), workbench (2), and height adjustment frame (7) is housed on the trolley (1), and height adjustment frame ( 7) The workbench (2) is installed, and the height adjustment frame (7) can adjust the height of the workbench (2), thereby adapting to the height of wheelsets of various diameters. When not working, the trolley (1) is pushed to the Adjust the support seat (4) on the side of the wheel, and change the height of the workbench (2), so that the derusting mechanism (3) can be smoothly placed on the outer ring of the bearing (14). Under the action of the return spring (11), the lever ( 10) The end with the oil stone is far away from the bearing outer ring (14).

[0018] 2. Please refer to the attached figure 1 : workbench (2) is made up of motor (6), two support bases (4) and derust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com