Mold changing trolley capable of centering mold and making mold be universal

A mold trolley and mold technology, applied in the field of mold changing trolleys, can solve the problems of different heights, low positioning accuracy, poor versatility, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

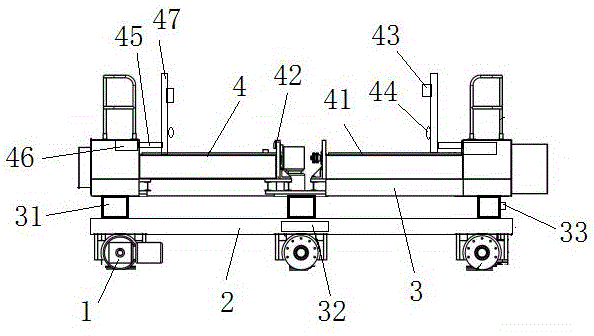

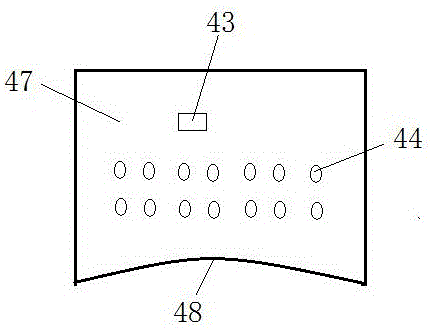

[0030] Such as figure 1 and figure 2 As shown, a mold changing trolley capable of automatically centering molds includes a pulley 1, a chassis 2, a jacking floor 3, a lifting column 31, a lifting column driving motor 32, a displacement sensor 33, a mold changing platform 4, a roller Main technical features such as column 41, side plate 42, proximity sensor 43, roller 44, telescopic rod 45, telescopic rod drive motor 46, guide slide plate 47 and arc groove 48.

[0031] A mold changing trolley capable of automatically centering molds, comprising a pulley 1, a chassis 2, a jacking bottom plate 3, a mold changing platform 4 and a centering mechanism.

[0032] The jacking base plate is fixed on the chassis top by several lifting columns 31, and the height of the jacking base plate can be lifted. The lifting column is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com