Device and method for performing jet spinning by means of melt-blown ultrafine fiber

A superfine fiber, air-jet spinning technology, applied in the field of fiber manufacturing, can solve the problems of antibacterial, heat insulation, sound absorption, limited filtration and adsorption, limited yarn specific surface area, thick details, and many yarn defects, and achieves melt-blown The effect of high fiber content, low fineness and quality, and low hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

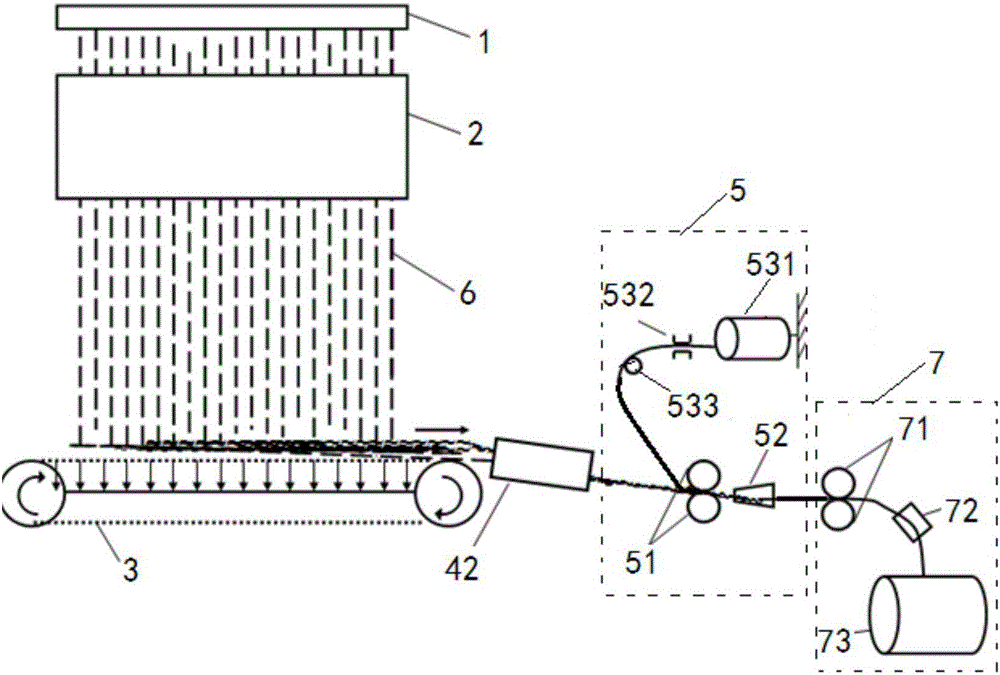

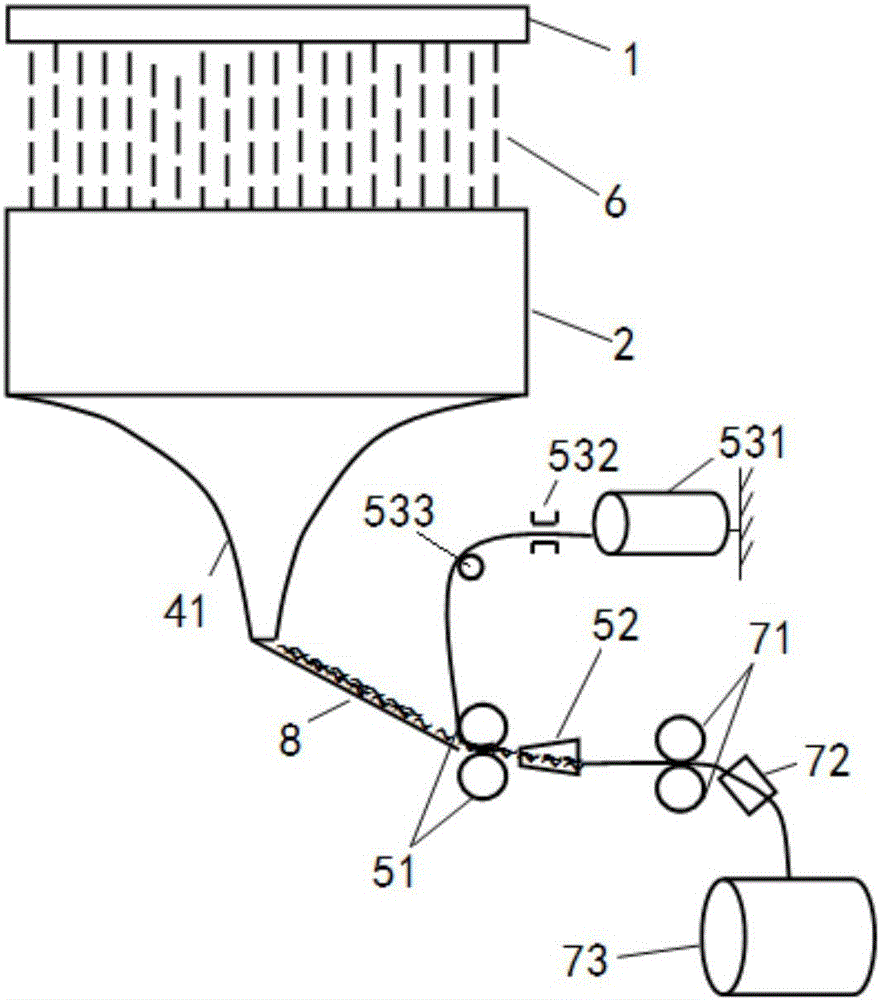

[0077] A method of air-jet spinning utilizing melt-blown superfine fibers, comprising the following steps:

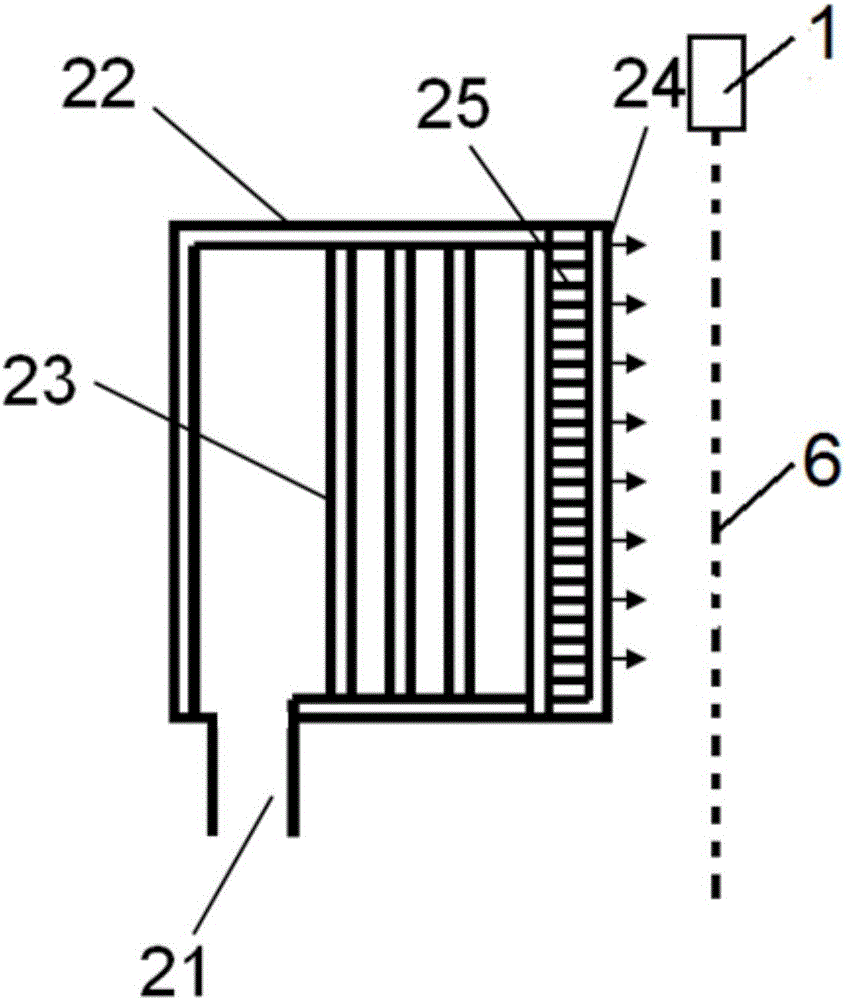

[0078] (1) Preparation of melt-blown ultrafine fibers: After PP pellets enter the hopper of the melt-blown device, they are melted by the screw extruder, and the metering pump is quantitatively sprayed out from the spinneret of the melt-blown die. The temperatures were 260°C, 260°C, 270°C, and 270°C, respectively. The extruded melt-blown ultrafine fibers are first rapidly drawn and drawn under the hot air on both sides. The temperature of the hot air is 220°C, the pressure of the hot air is 0.5MPa, and the speed of the melt-blown is 10m / min. After the fiber is drawn by hot air, it is cooled in the cold air box. The temperature of the cooling air is 8°C, and the flow rate of the cooling air is 15000m 3 / h, the cooling wind pressure is 1500Pa, the wind speed is 2m / s, and the average diameter of the obtained melt-blown ultrafine fibers is 1 μm.

[0079] (2) Cooling and c...

Embodiment 2

[0083] A method of air-jet spinning utilizing melt-blown superfine fibers, comprising the following steps:

[0084] (1) Preparation of meltblown ultrafine fibers: After the PP pellets enter the hopper, they are melted by the screw extruder, and the metering pump is quantitatively sprayed out from the spinneret of the meltblown die head. The temperatures in the four zones of the screw extruder are respectively 260 ℃, 260℃, 270℃, 270℃. The extruded melt-blown ultrafine fibers are first rapidly drawn and drawn under the hot air on both sides. The temperature of the hot air is 220°C, the pressure of the hot air is 0.5MPa, and the speed of the melt-blown is 10m / min. After the fiber is drawn by hot air, it is cooled in the cold air box. The temperature of the cooling air is 8°C, and the flow rate of the cooling air is 15000m 3 / h, the cooling wind pressure is 1500Pa, the wind speed is 2m / s, and the average diameter of the obtained melt-blown ultrafine fibers is 1 μm.

[0085] (2) ...

Embodiment 3

[0089] A method of air-jet spinning utilizing melt-blown superfine fibers, comprising the following steps:

[0090] (1) Preparation of meltblown ultrafine fibers: After the PP pellets enter the hopper, they are melted by the screw extruder, and the metering pump is quantitatively sprayed out from the spinneret of the meltblown die head. The temperatures in the four zones of the screw extruder are respectively 260 ℃, 260℃, 270℃, 270℃. The extruded melt-blown ultrafine fibers are first rapidly drawn and drawn under the hot air on both sides. The temperature of the hot air is 220°C, the pressure of the hot air is 0.5MPa, and the speed of the melt-blown is 10m / min. After the fiber is drawn by hot air, it is cooled in the cold air box. The temperature of the cooling air is 8°C, and the flow rate of the cooling air is 15000m 3 / h, the cooling wind pressure is 1500Pa, the wind speed is 2m / s, and the average diameter of the obtained melt-blown ultrafine fibers is 1 μm.

[0091] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com