Auxiliary Programming Method for Execution Program of NC Machining Equipment

A technology for processing equipment and executing programs, applied in the field of numerical control, can solve problems such as long-term programming, debugging and optimization, high requirements for professional knowledge, and inability to use manual traction, so as to expand automatic optimization functions, reduce product quality, and improve The effect of machining efficiency and machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

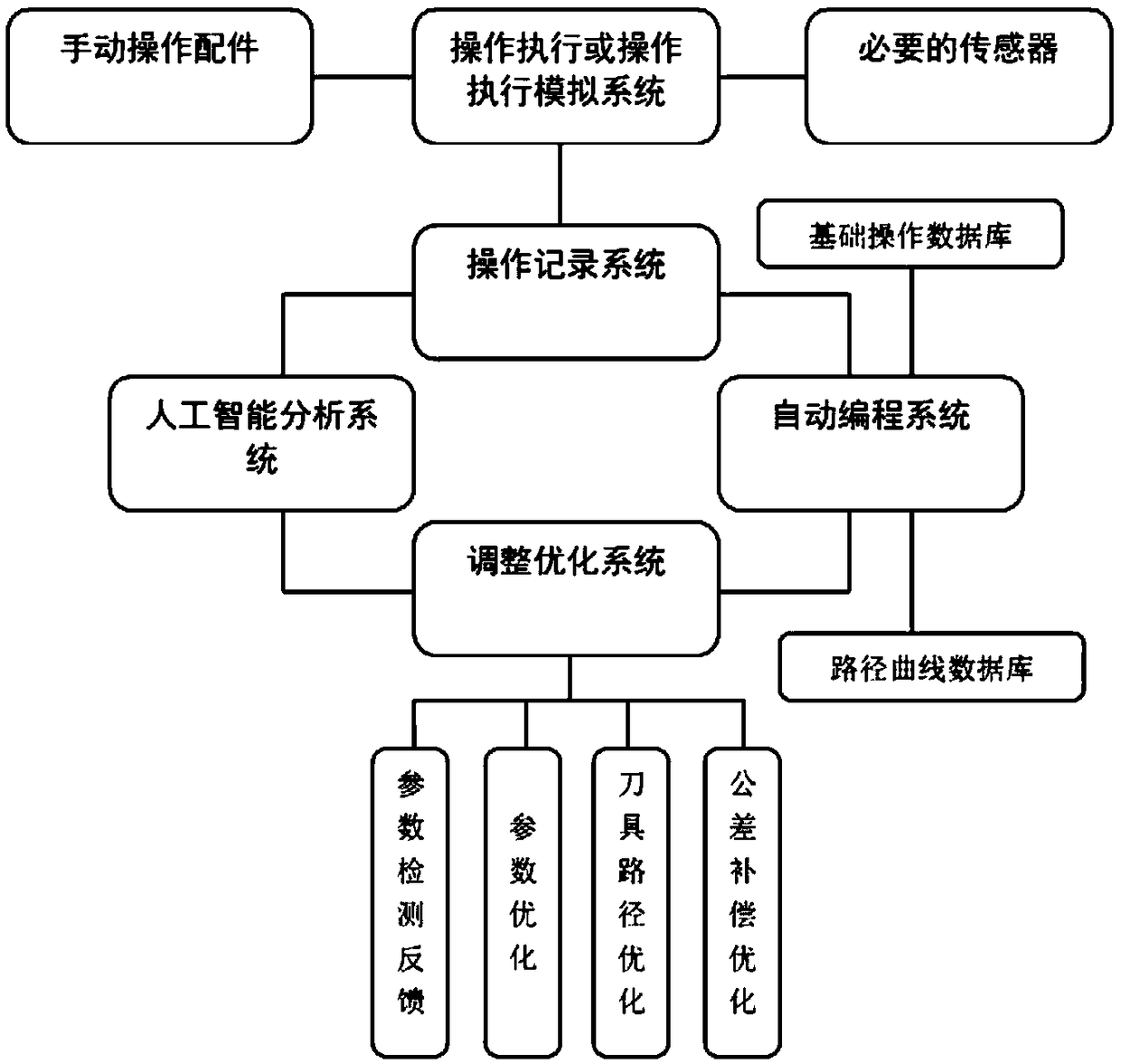

[0021] Such as figure 1 As shown, the auxiliary programming method of the CNC machining equipment execution program in this embodiment involves the technical requirements of the workpiece, the operation execution simulation system, the operation recording system, the artificial intelligence analysis system, the automatic programming system and the parameter adjustment and optimization system, and finally the automatic Generate optimized NC programs.

[0022] The technical requirements of the workpiece refer to a series of parameter requirements such as the shape, roughness, and precision of the target product. Based on these requirements, technical operators manually and program the workpiece to process the workpiece from the blank into a product that meets the technical requirements. .

[0023] The operation execution simulation system described above is mainly a system that provides manual and program programming operation modes for numerical control processing equipment, a...

Embodiment 2

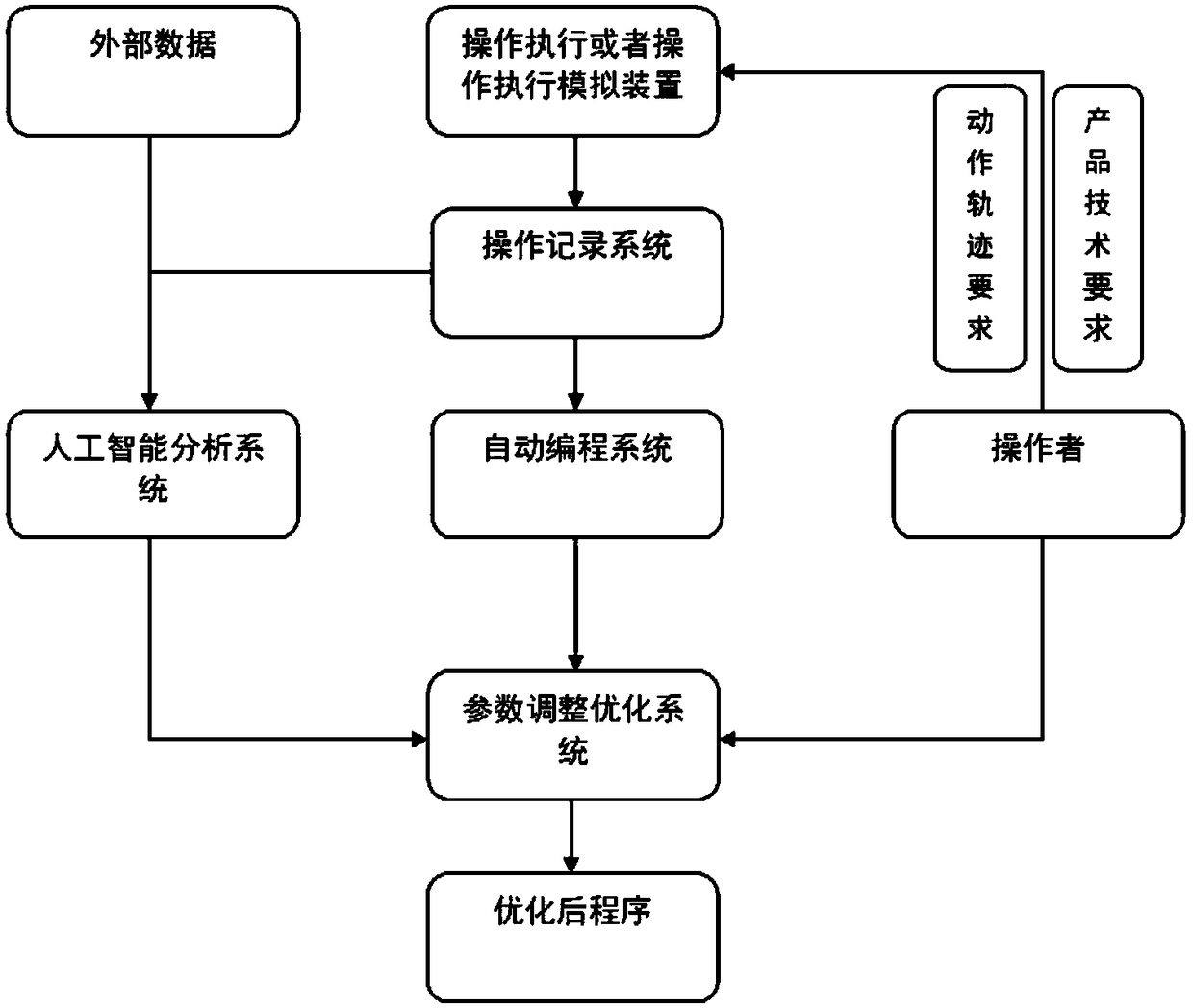

[0035] Such as figure 2 As shown, the auxiliary programming method of the execution program of the numerical control processing equipment in this embodiment involves content including motion trajectory requirements, operation execution simulation system, operation recording system, automatic programming system and parameter adjustment and optimization system, and finally automatically generates the optimized numerical control program.

[0036] The motion track requirements refer to the requirements for industrial robots to complete a specified action, realize a certain function, locate coordinates, etc., and at the same time combine the allowable work space and obstacle avoidance requirements. Based on these requirements, technical operators manually operate and program to determine the trajectory and motion curve of the industrial robot's mechanical arm to complete the specified action.

[0037] The operation execution simulation system mentioned above mainly refers to a sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com