Walnut picking machine

A technology for picking machines and walnuts, which is applied in the directions of picking machines, harvesters, agricultural machinery and implements, can solve the problems of easily damaged branches, reduced walnut yield, high labor intensity, etc., achieves convenient use and operation, improves picking efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

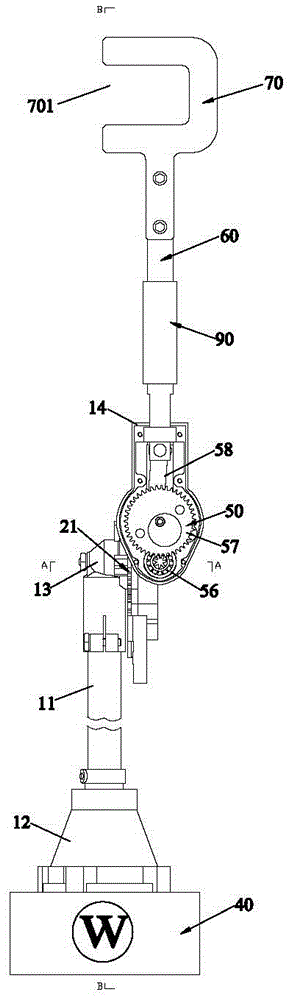

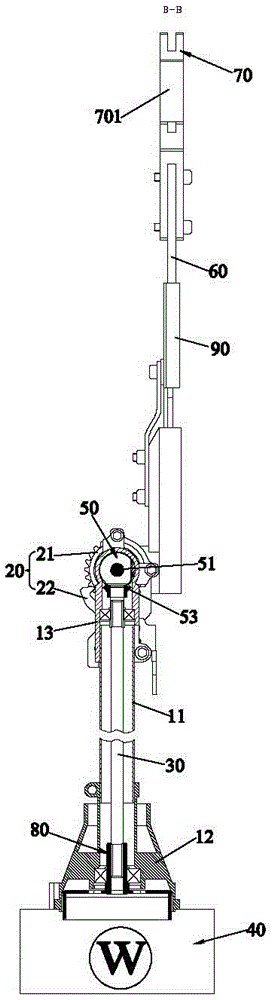

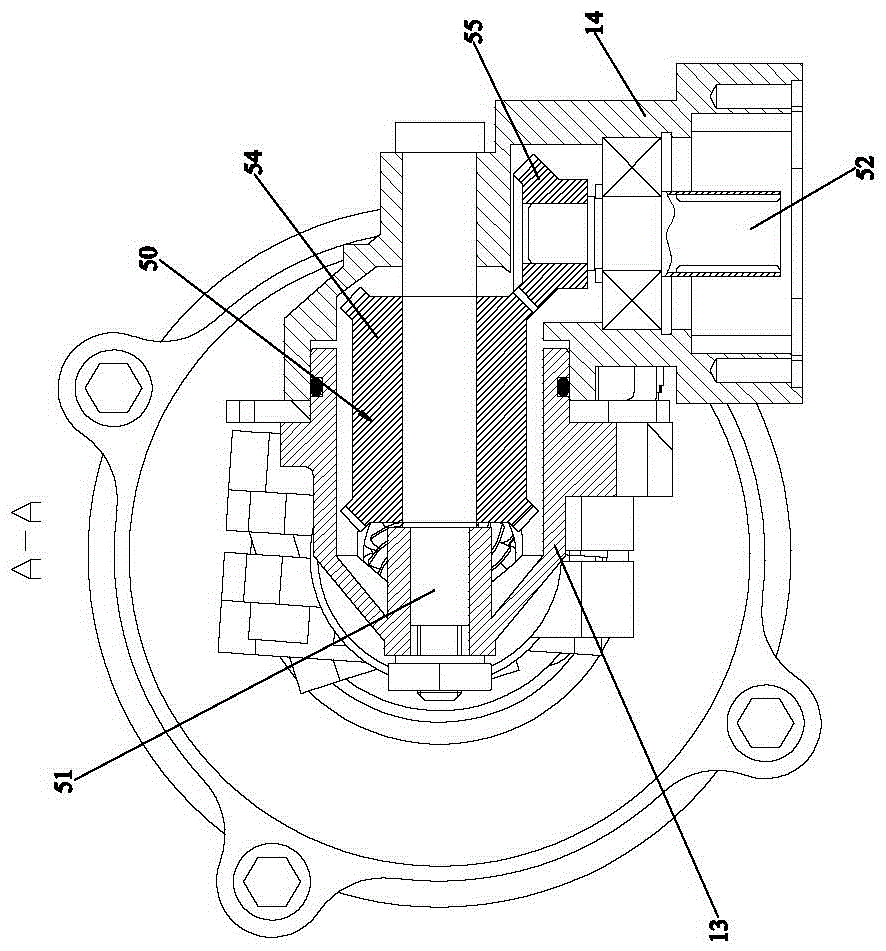

[0029] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the support main rod 11, the fixed seat 12, the first gear seat 13, the second gear seat 14, the angle adjustment mechanism 20, the linkage shaft 30, Driving mechanism 40, gear transmission mechanism 50, linkage rod 60 and picking head 70.

[0030] The fixed seat 12 is fixed on the lower end of the supporting main rod 11, the first gear seat 13 is fixed on the upper end of the supporting main rod 11, and the second gear seat 14 is swingably mounted on the first gear seat 13; the angle adjustment mechanism 20 is arranged between the first gear seat 13 and the second gear seat 14, specifically, the angle adjustment mechanism 20 includes a steering tooth 21 and a positioning card 22, and the steering tooth 21 is fixed on the second gear seat 14 with the second The gear seat 14 swings, and the positioning card 22 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com