Squirrel cage electric airflow bearing cotton and fruit picking machine

A squirrel-cage, picking machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high impurity rate of cotton wool, difficult adjustment of suction force, loss of cotton wool, etc., to achieve good safety performance and reduce labor force. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

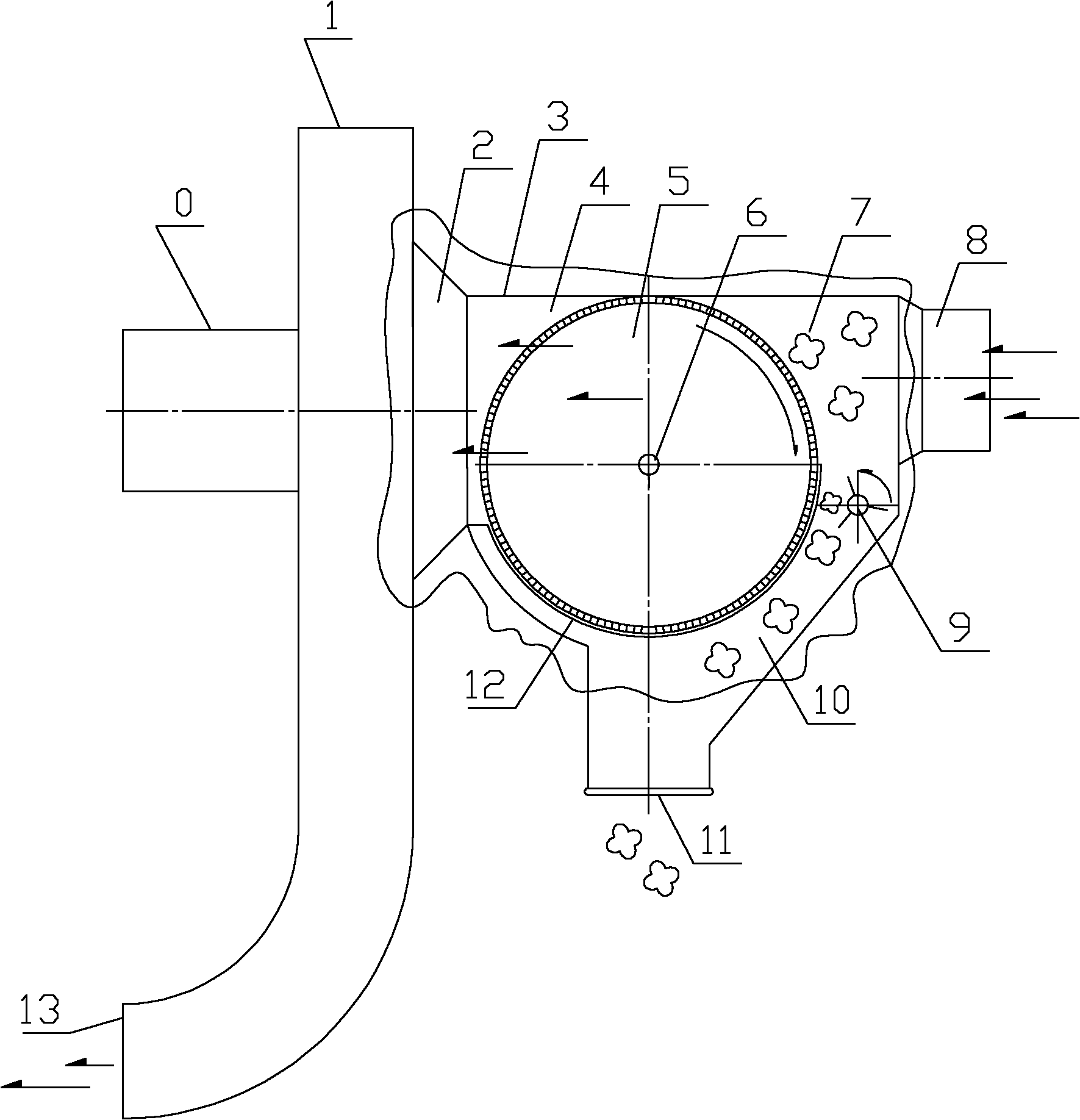

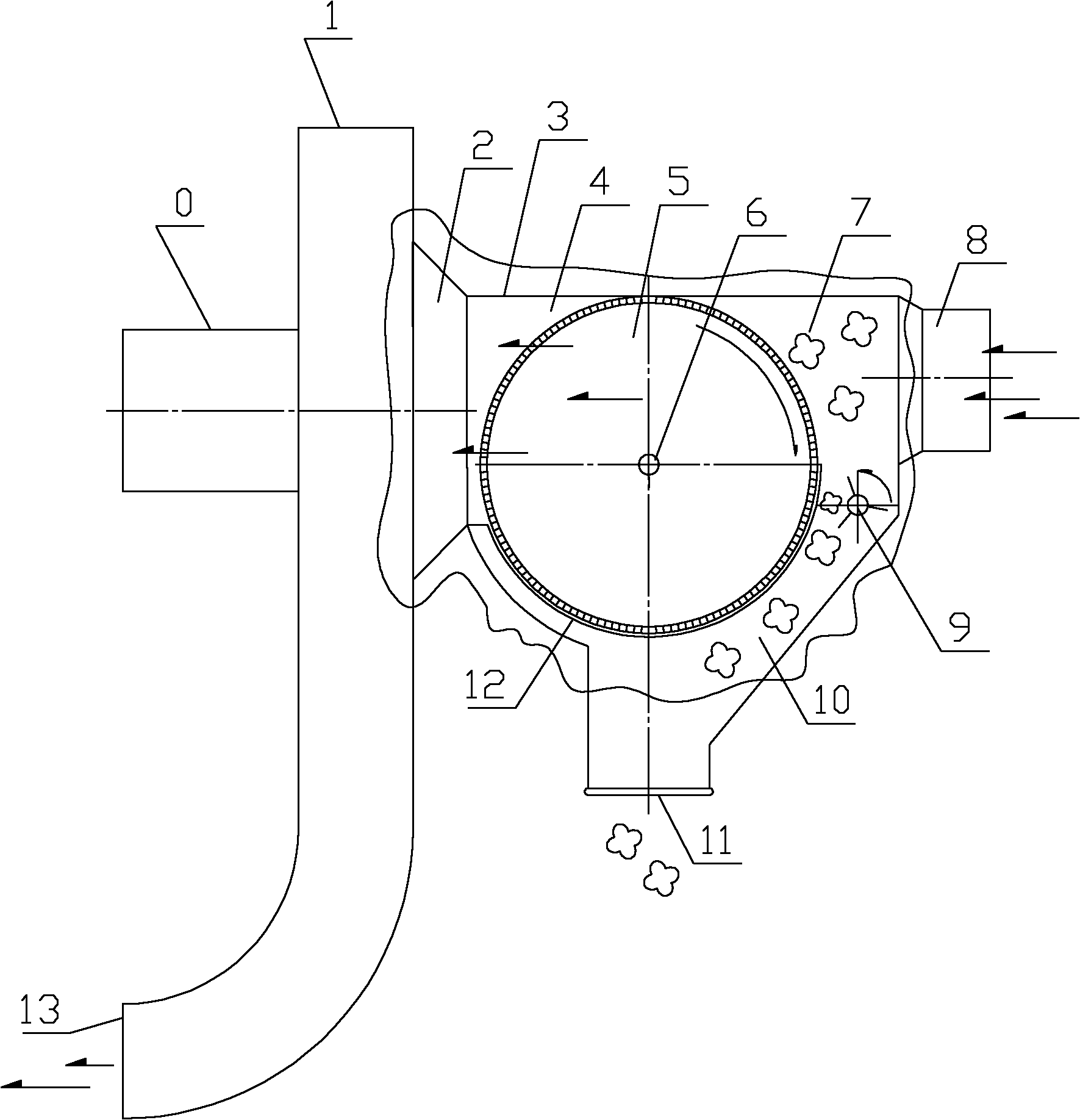

[0012] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0013] As shown in the accompanying drawings, when the DC motor 14 starts, it drives the suction fan 1 to rotate, and the rotation of the suction fan 1 generates directional wind force. There is a suction port on the right side of the suction fan 1, and the suction port is connected to the shell 3 through the connection plate 2. Under the action of directional wind force, the air inlet chambers 4 and 7 in the shell 3 bring the cotton and fruit in the manipulator connection port 8, and the shell 3 is provided with a squirrel-cage separation drum 5, which is installed through the main shaft 6 On the shell 3, under the ventilating separation effect of the squirrel-cage separation drum 5, the cotton and the fruit are turned 90° clockwise in the shell 3, and finally fall to the fallen flower and fruit channel 10, and fall out by the outlet 11.

[0014] The squirrel-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com