cotton mop

A collodion mop and collodion technology, which is applied in the direction of cleaning carpets, floors, household appliances, etc., can solve the problems of poor mopping effect, easy shaking, and inability to adjust the elasticity of the collodion mop head, so as to improve efficiency and achieve good stability. Performance, easy to replace the effect of the collodion head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

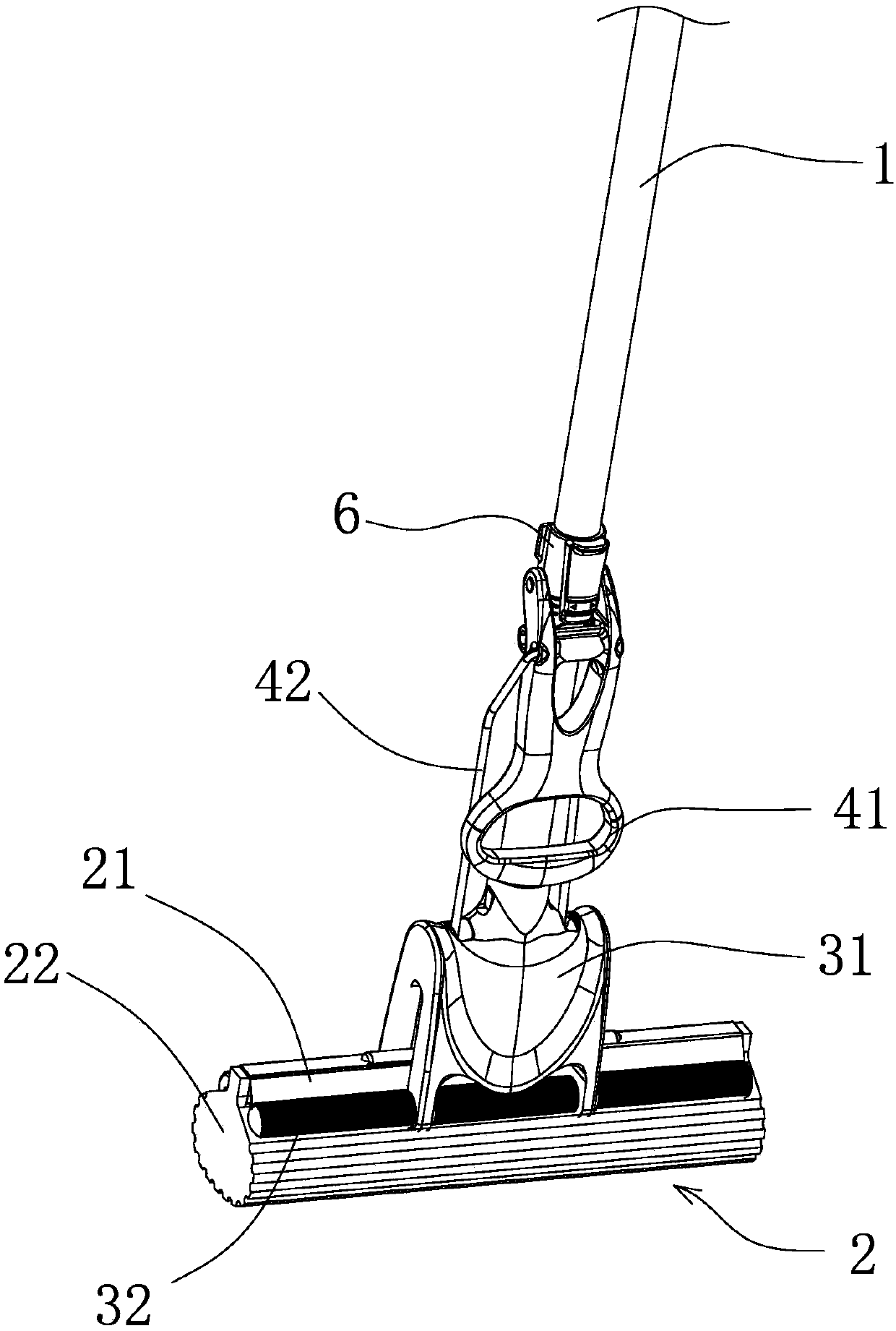

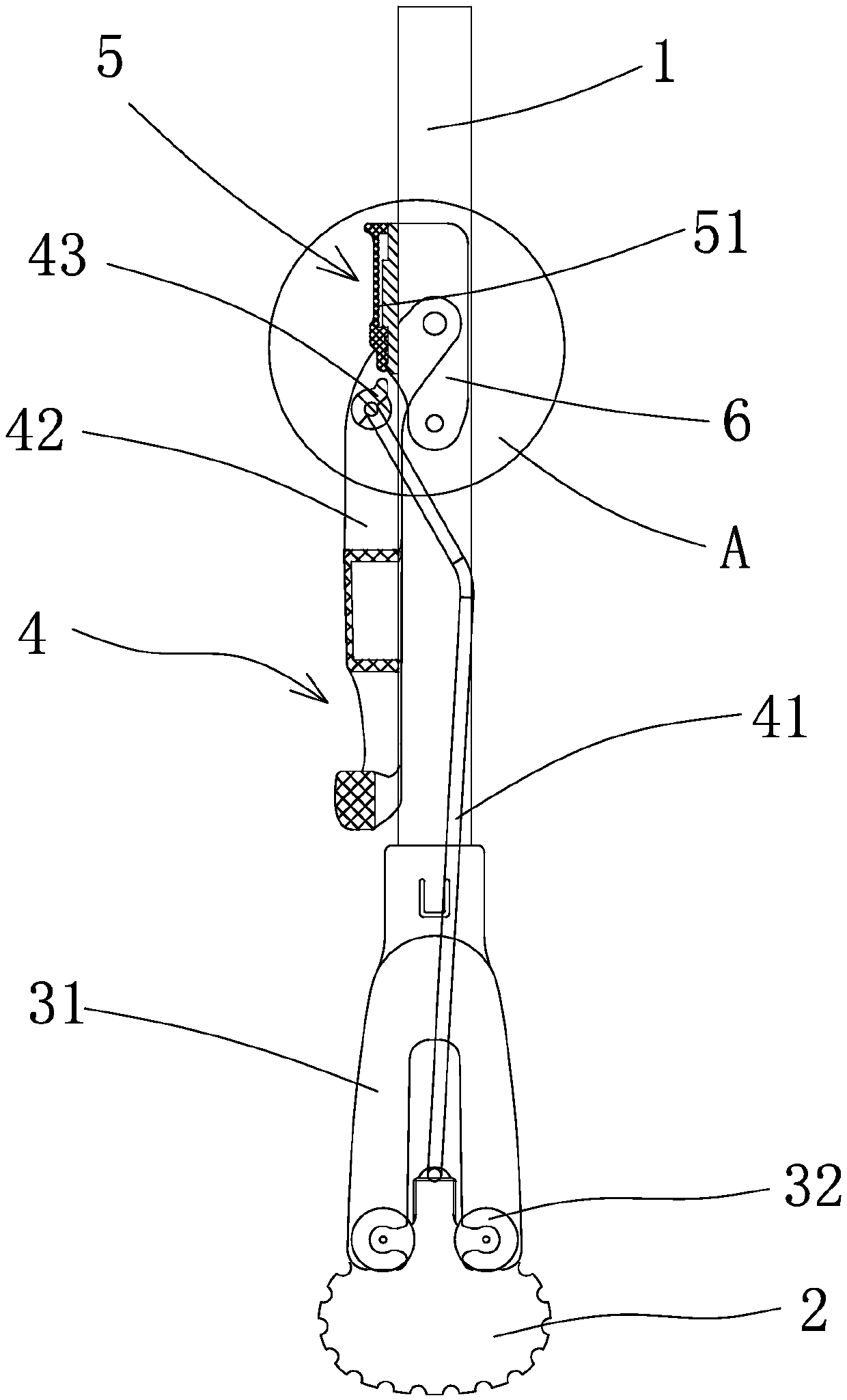

[0040] Such as Figure 1 to Figure 13 As shown, the present embodiment includes a mop rod 1 and a collodion head 2, a water squeeze frame 31 is provided at one end of the mop rod 1, and a water squeeze structure is arranged on the water squeeze frame 31, and the collodion head 2 is located below the water squeeze structure , the collodion head 2 is connected with a control mechanism 4 that can drive the collodion head 2 to move relative to the water-squeezing structure and can position the collodion head 2. Finally, the position of the collodion head 2 relative to the water squeezing structure can be adjusted so that the upper part of the collodion head 2 abuts against the water squeezing structure to adjust the adjustment mechanism 5 for the tightness of the collodion head 2. The degree of tightness between the cotton head 2 and the squeeze roller 32 can be adjusted easily when the collodion head 2 becomes loose, so as to ensure that the collodion head 2 and the squeeze rolle...

Embodiment 2

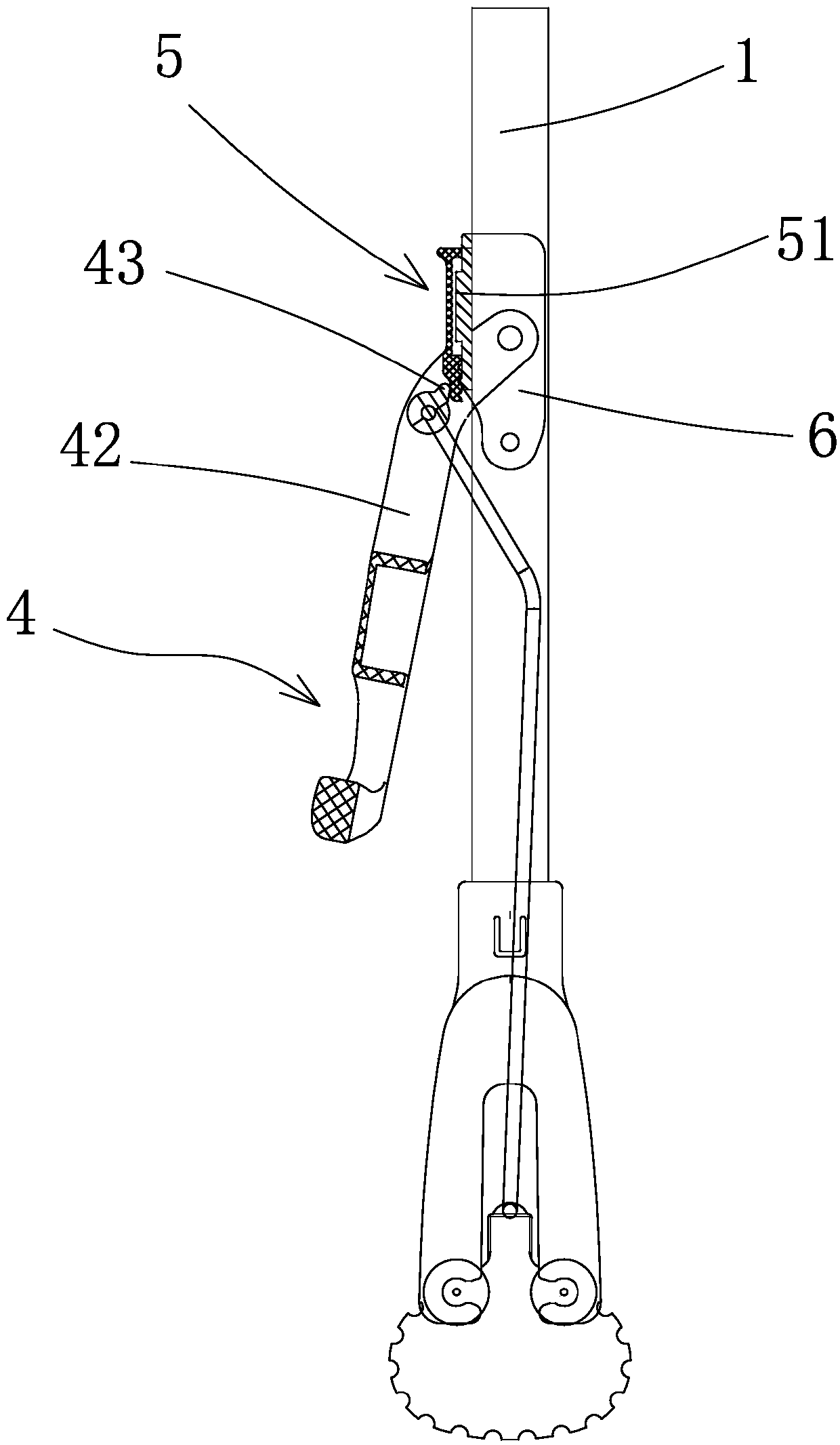

[0056] Such as Figure 14 As shown, the adjustment mechanism 5 in this embodiment is arranged between the wrench 42 and the mop rod 1, and the adjustment mechanism 5 can adjust the position of the connection between the inner end of the wrench 42 and the mop rod 1 relative to the axial direction of the mop rod 1 so as to realize the collodion Head 2 tightness adjustment.

[0057] Specifically, the adjustment mechanism 5 includes a moving seat 8 that is arranged on the mop rod 1 and can move axially relative to the mop rod 1. The inner end of the wrench 42 is hinged with the moving seat 8. , the rotating sleeve 9 is connected with the moving seat 8 for axial positioning and circumferential rotation.

[0058] In order to facilitate the replacement of the collodion head 2, the collodion head 2 is connected to the pull rod 41 through a detachable structure 7, and the rotating sleeve 9 can drive the collodion head 2 to move up and down relative to the squeezing structure through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com