A Blade Compensation Technology of Underwater Two-axis Linkage Pelletizer

A granulator and shaft linkage technology, which is applied in metal processing and other directions, can solve the problems of high equipment failure rate, inconvenient replacement and maintenance, complex structure, etc., and achieve the effect of ensuring safe production, convenient maintenance and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

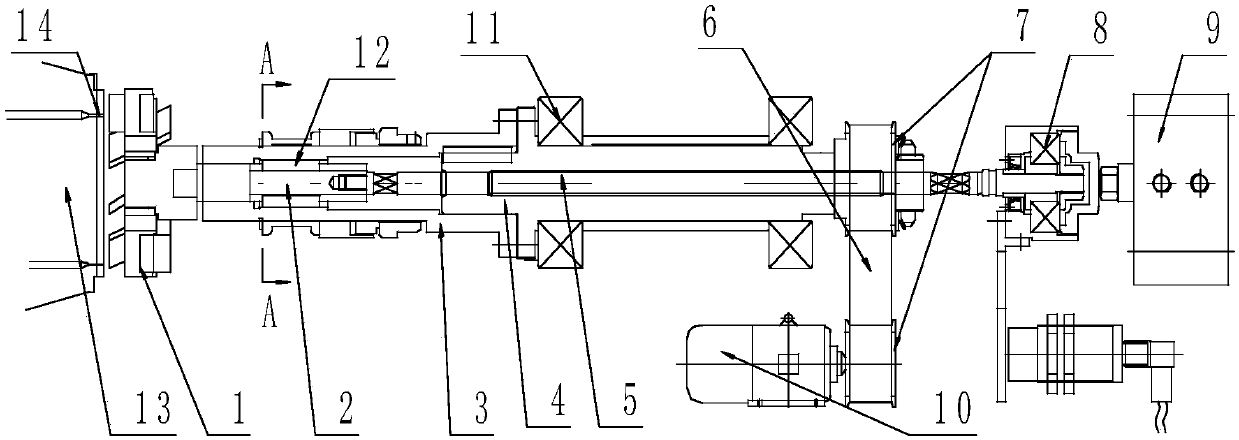

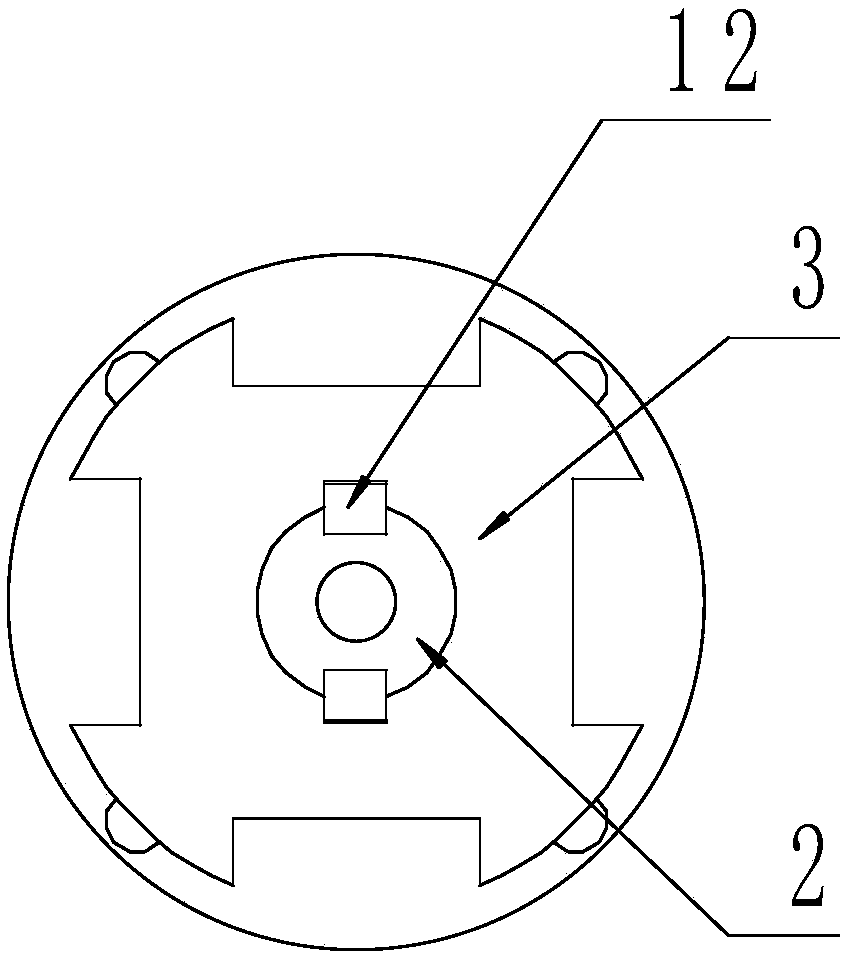

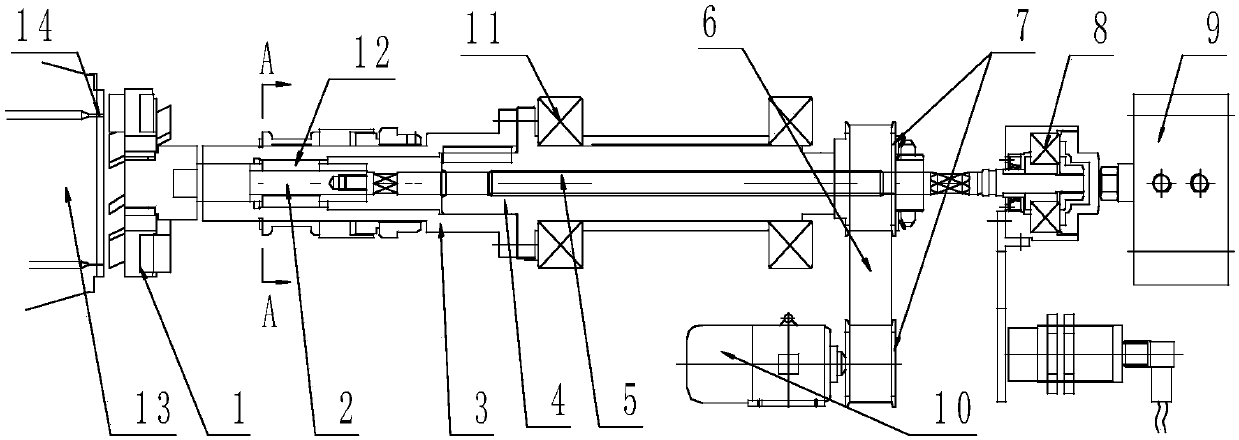

[0023] The outer two ends of the transmission shaft 4 are respectively provided with two coaxial bearing coupling shaft seats 11, one end of the transmission shaft 4 is provided with a connection transition shaft 3, a connection flange is provided between the transmission shaft 4 and the connection transition shaft 3, and the transmission shaft 4 and the connection transition Fastening bolts are arranged between the connecting flanges of the shaft 3, and the transmission shaft 4 and the connecting transition shaft 3 form a rotating shaft; the axial center of the transmission shaft 4 and the connecting transition shaft 3 is reserved with a concentric shaft hole;

[0024] The central shaft hole of the transmission shaft 4 is provided with an axial push shaft 5, and the central shaft hole connected with the transition shaft 3 is provided with a cutter head shaft 2; one end of the axial push shaft 5 is provided with a thread connection corresponding to one end of the cutter head sha...

Embodiment 2

[0030] The connecting transition shaft 3 drives the cutter head shaft 2, the cutter head 1 and the blade to rotate at high speed coaxially through the connecting shaft slider 12, and the blade corresponds to the discharge port 14 to rotate and cut the extruded water-cooled and formed raw material.

Embodiment 3

[0032] While the blade rotates at high speed for cutting, the axial pushing device 9 drives the axial pushing shaft 5 to perform axial displacement through the expansion and contraction of the piston rod, and the force of axial displacement of the axial pushing shaft 5 is transmitted to the cutter head shaft 2 and the cutter head 1 in sequence , the blade, so that the rotating surface of the blade is flatly attached to the discharge port 14 of the die head 13 and rotated for cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com