Intelligent passive track trolley system with rotating function

A technology of track trolley and rotation function, which is applied in the direction of track system, load hanging components, traveling mechanism, etc., and can solve the problems of inability to realize the automatic rotation of the lifting workpiece, low efficiency, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

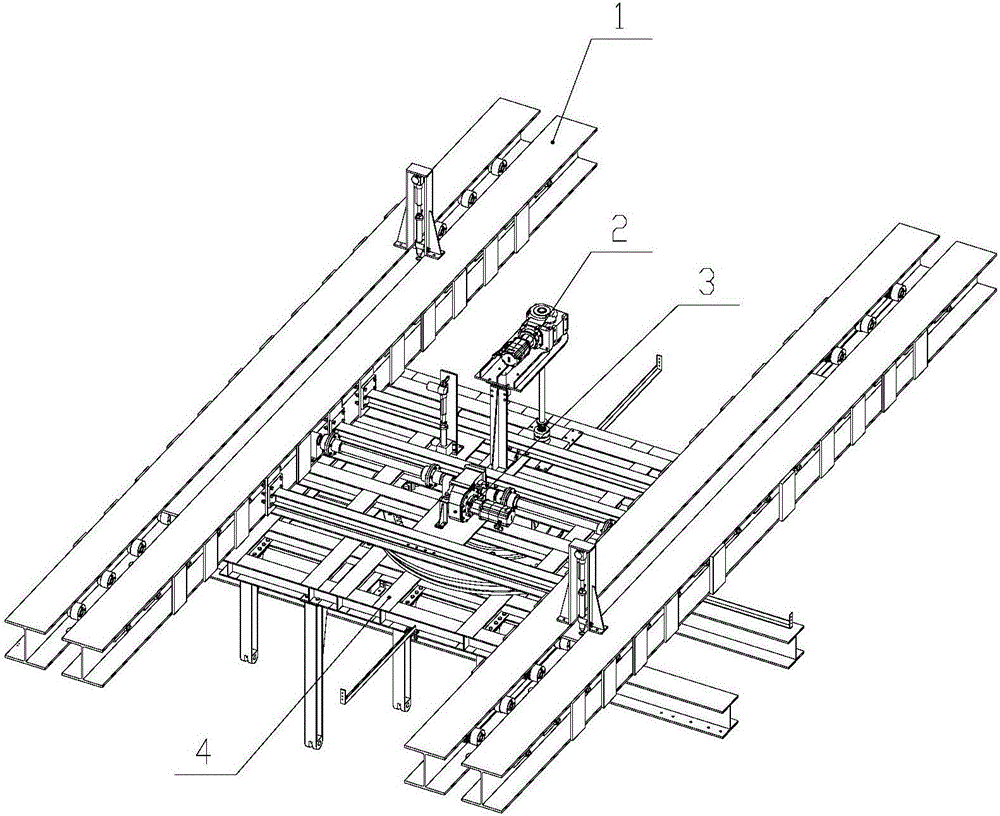

[0053] see Figure 1 to Figure 18 , an intelligent passive track trolley system with rotation function, comprising: a guide rail device 1, a rotation drive device 2, a guide rail drive device 3 and a passive track trolley device 4. Wherein: the guide rail driving device 2 and the rotation driving device 3 are installed in the middle of the guide rail device 1 by means of bolt connection, and the passive rail trolley device 4 is located inside the guide rail device 1 .

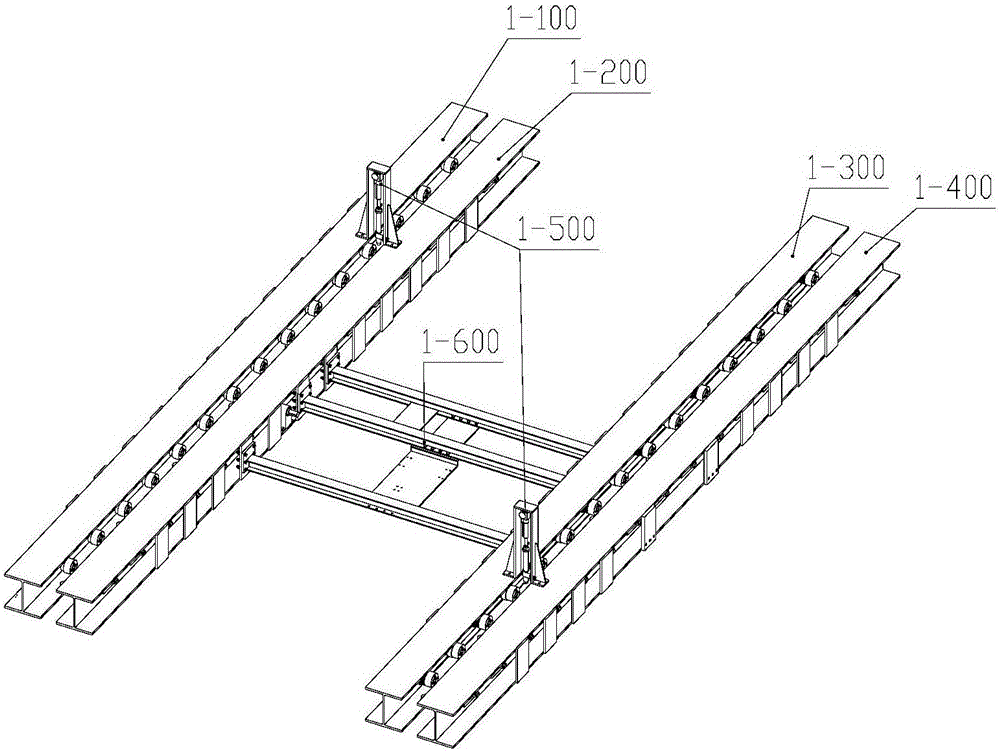

[0054] Such as figure 2 As shown, the guide rail device 1 is composed of a first guide rail 1-100, a second guide rail 1-200, a third guide rail 1-300, a fourth guide rail 1-400, a braking device 1-500 and a connecting device 1-600. Among them: the first guide rail 1-100 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com