Patents

Literature

67results about How to "Reduced alignment accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

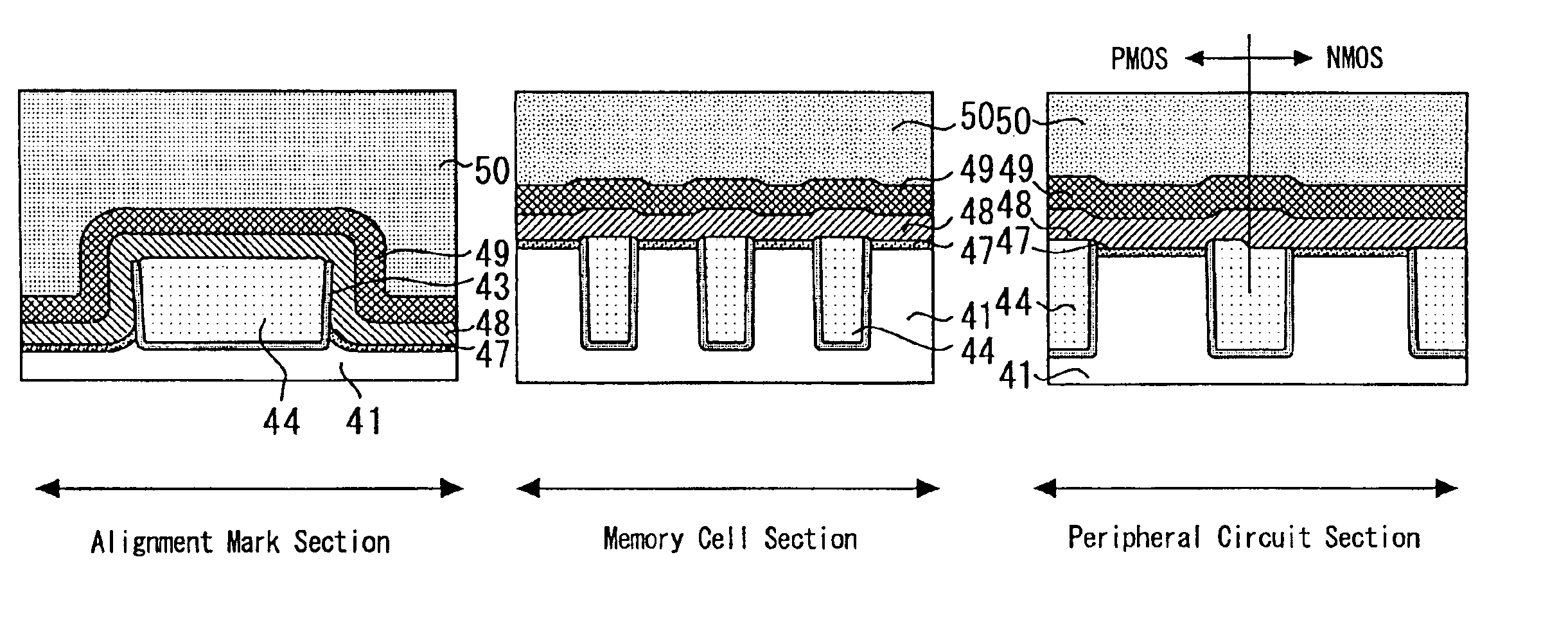

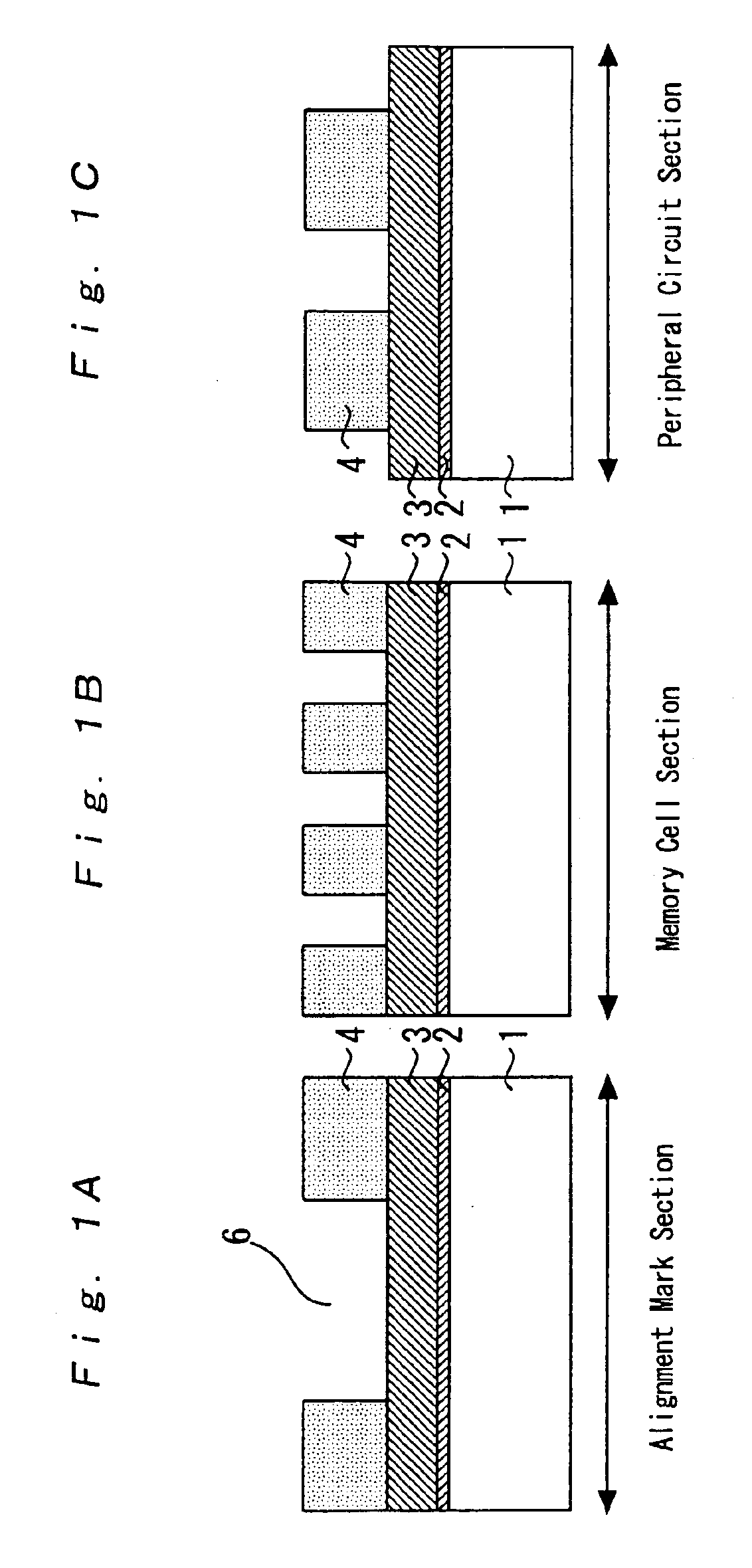

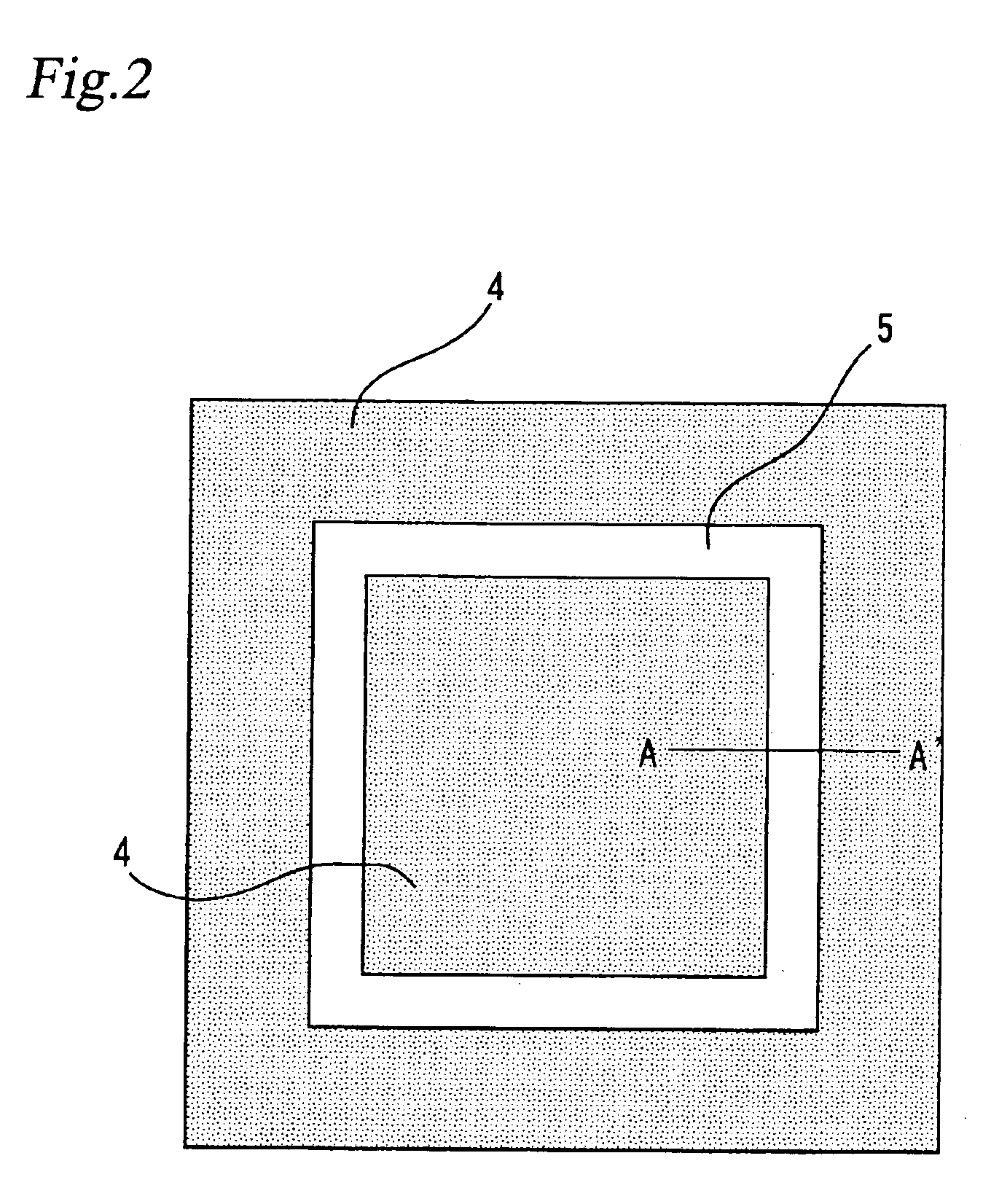

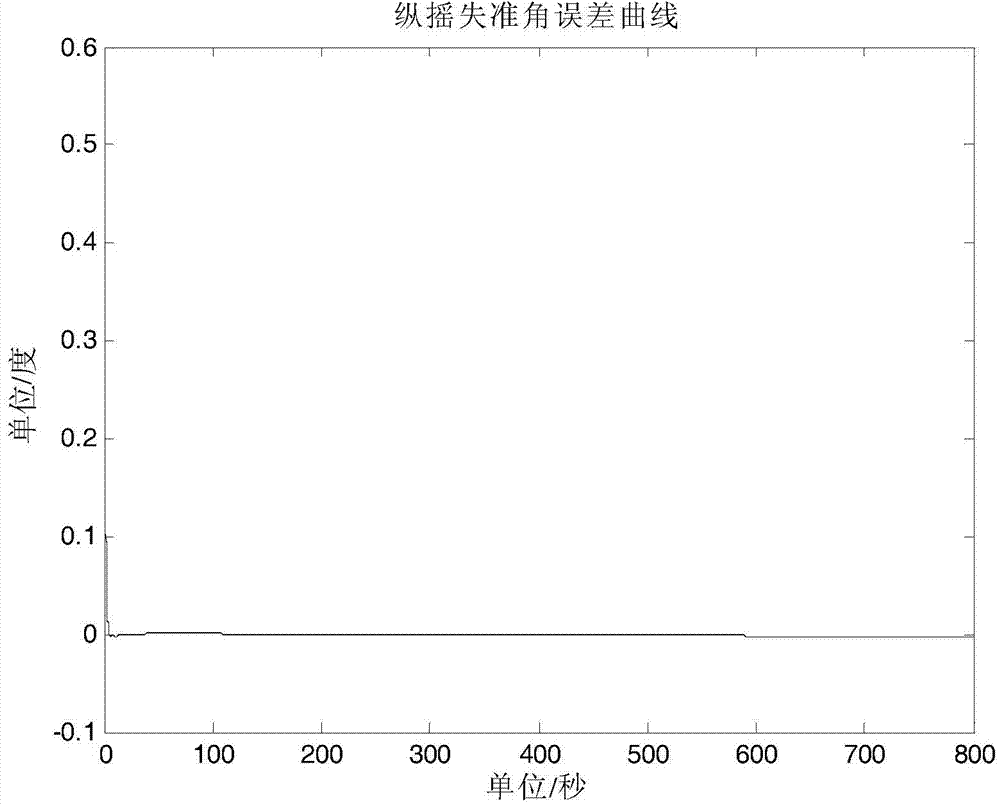

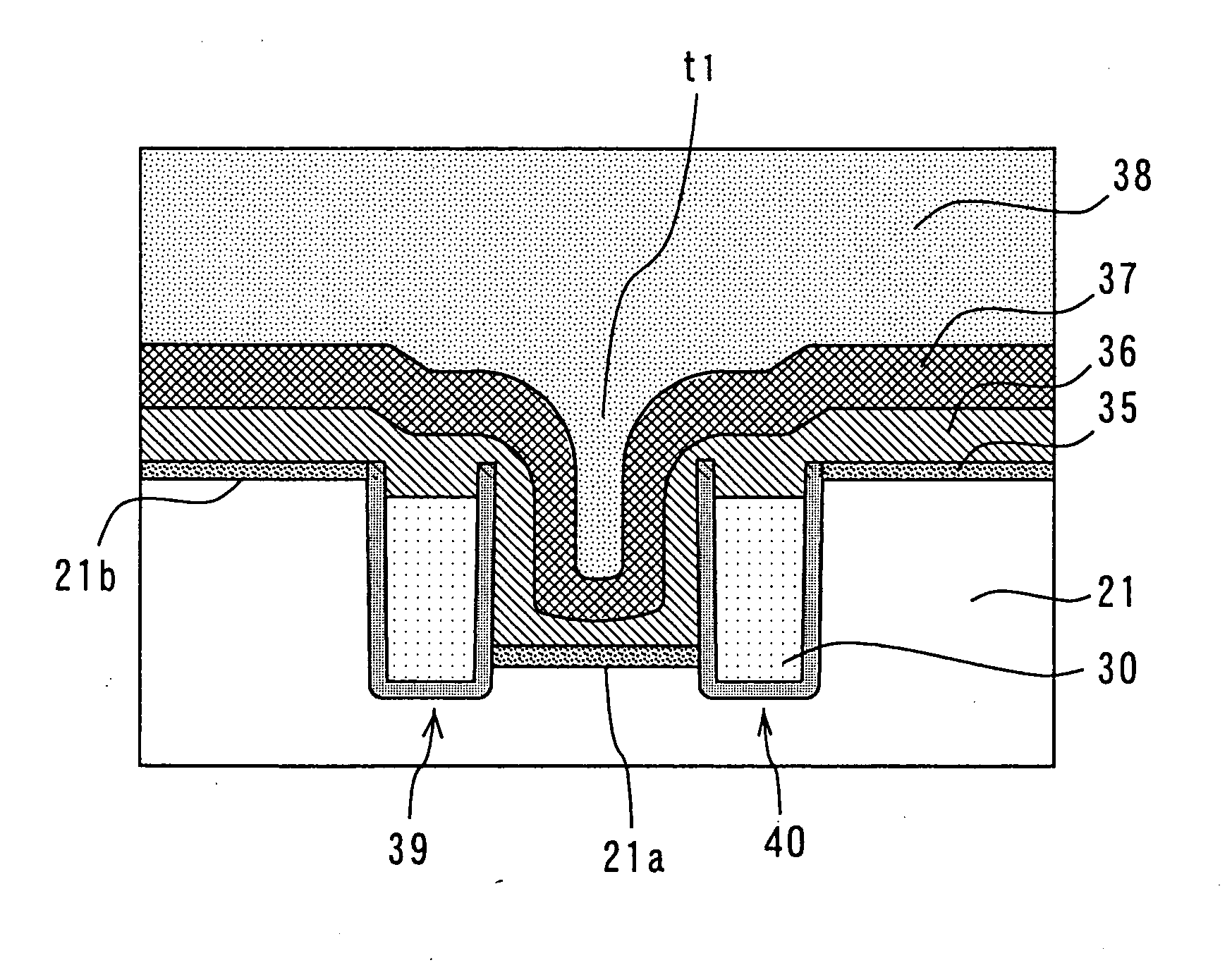

Method for manufacturing semiconductor device

ActiveUS6939777B2Reduce in quantityReduced alignment accuracyTransistorSemiconductor/solid-state device detailsSilicon oxideSemiconductor

An alignment mark section on a semiconductor substrate has two grooves which are filled with silicon oxide. The surface of the portion of the semiconductor substrate sandwiched by these grooves is lower than other portions of the semiconductor substrate to produce a step having a predetermined depth in the alignment mark section.

Owner:RENESAS ELECTRONICS CORP

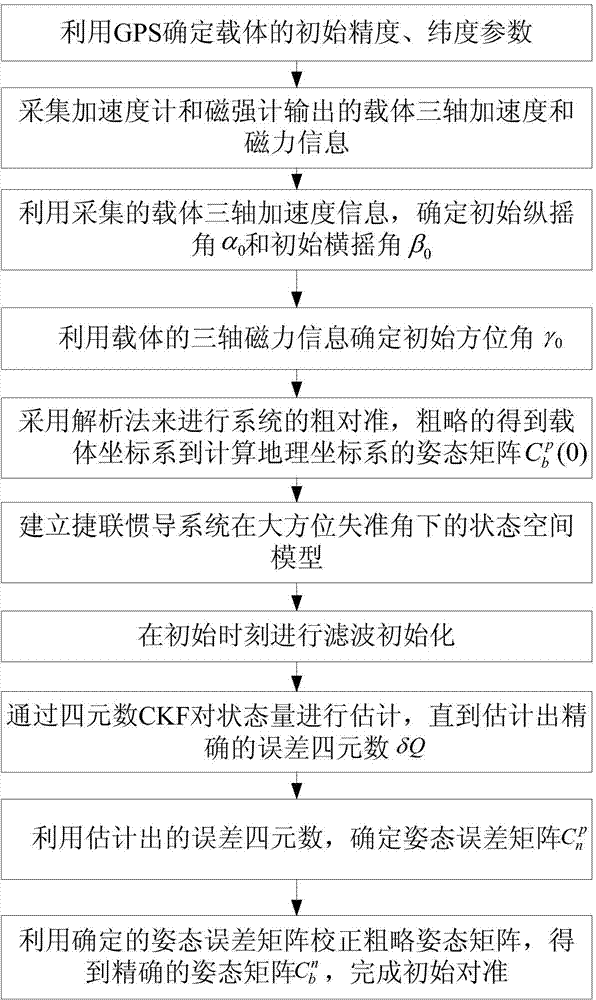

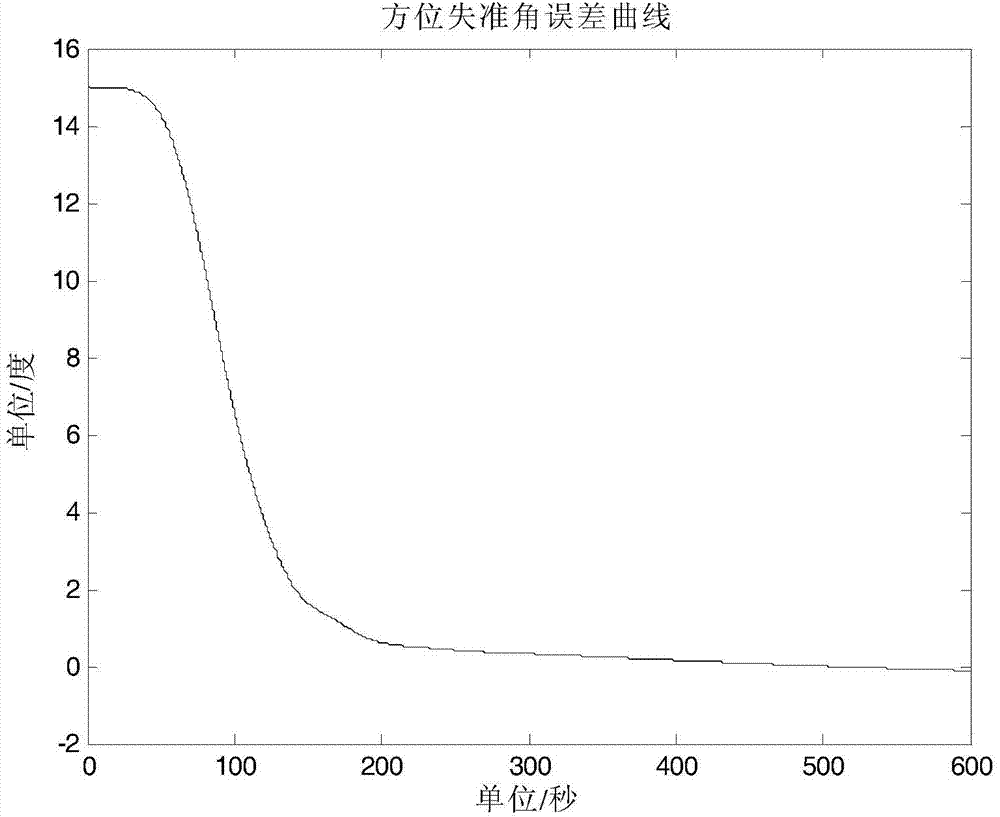

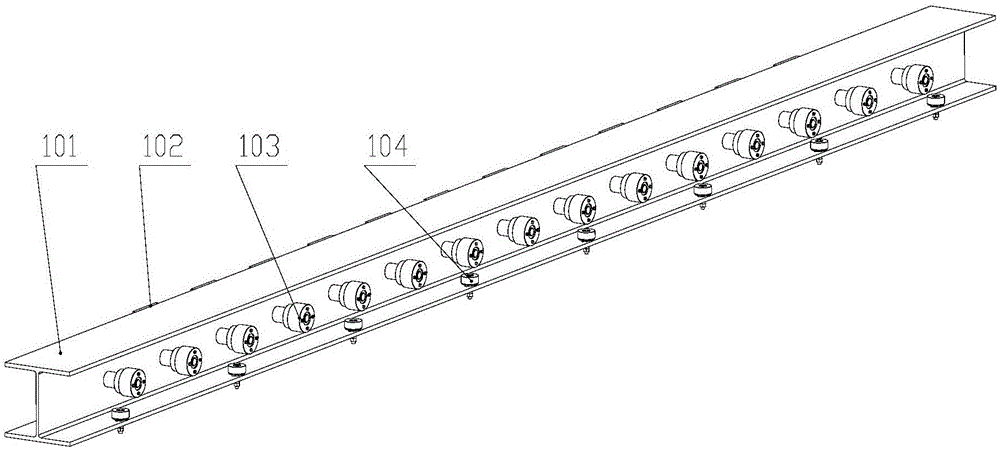

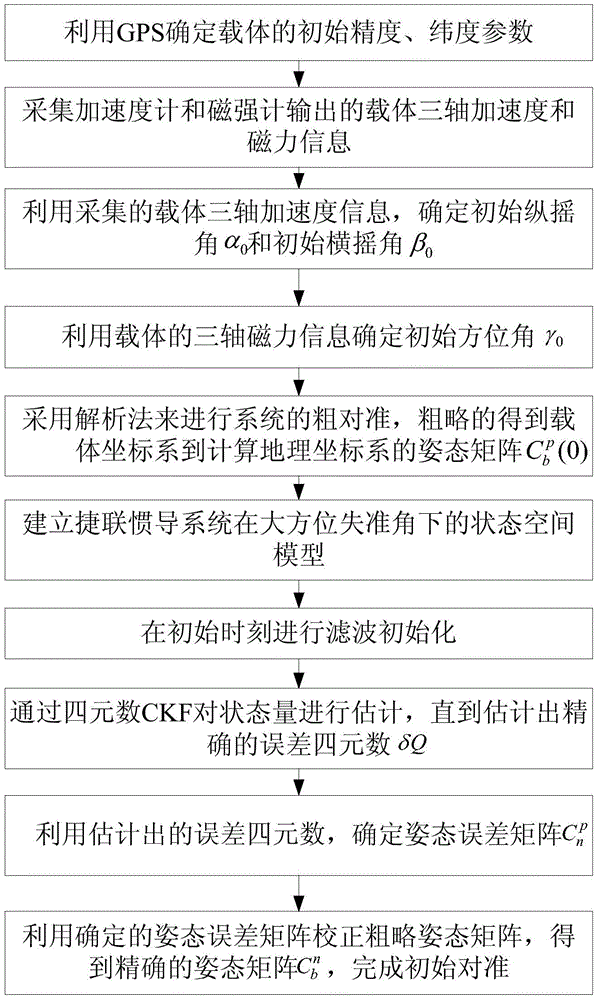

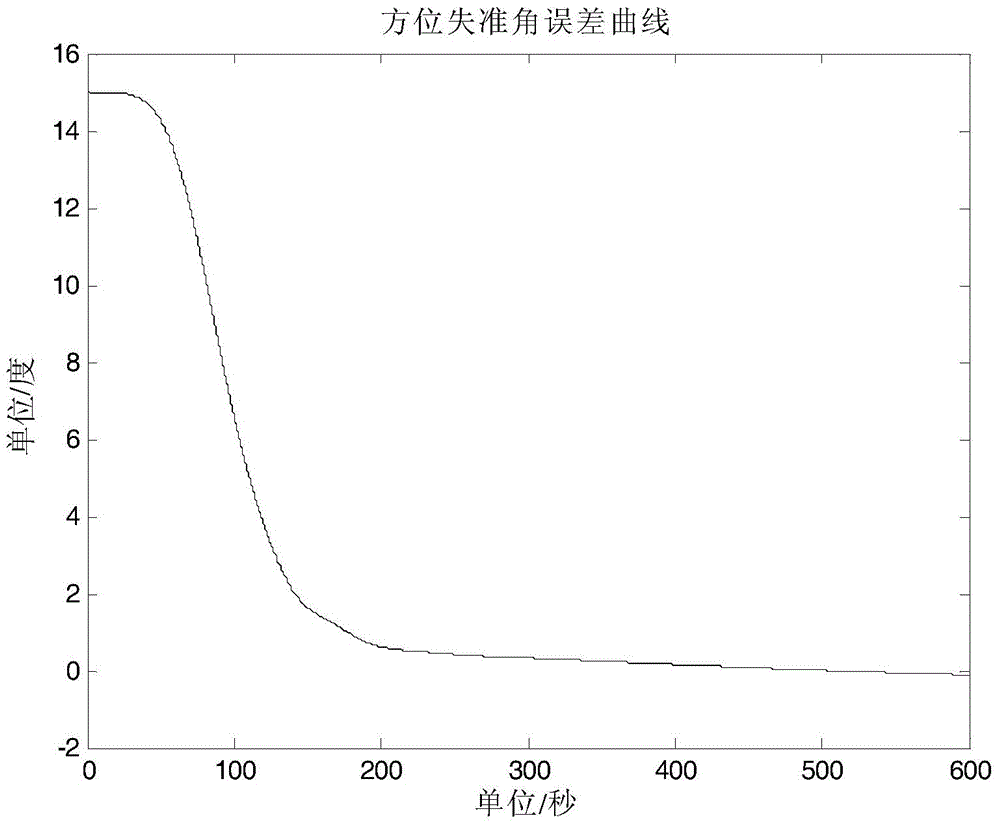

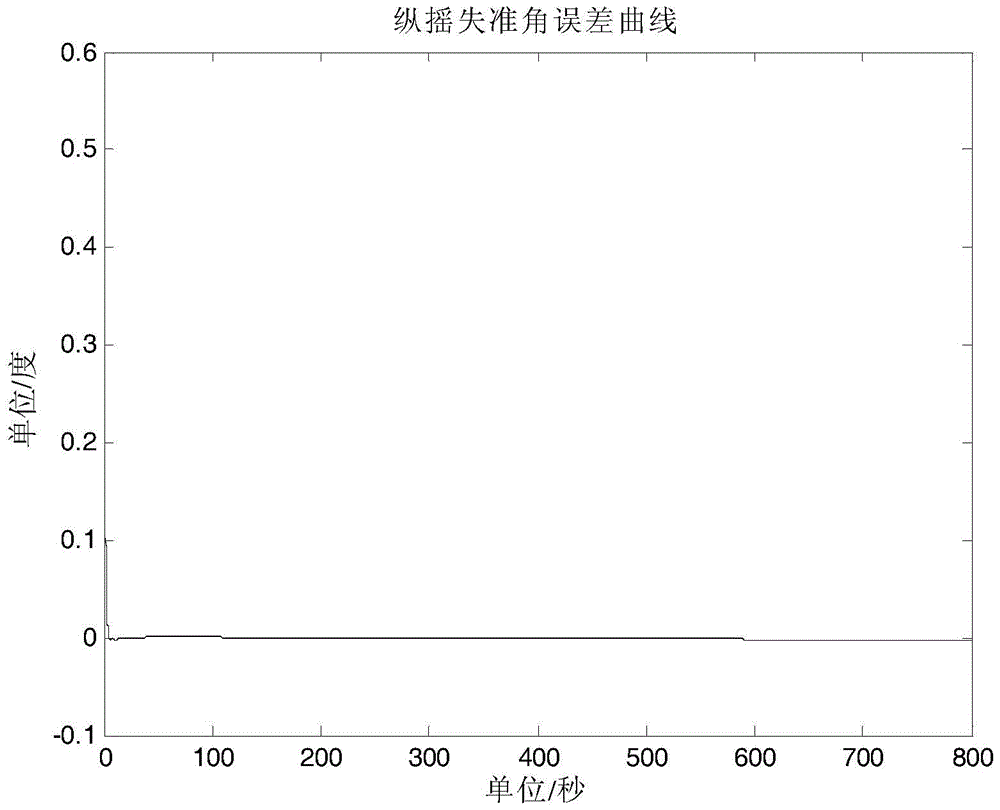

Low-precision inertial navigation initial alignment method based on quaternion CKF

InactiveCN103900608AReduced alignment accuracyEasy alignmentMeasurement devicesGyroscopeEarth's rotation

The invention provides a low-precision inertial navigation initial alignment method based on a quaternion CKF. The low-precision inertial navigation initial alignment method comprises the following steps: carrying out coarse alignment by utilizing measured values of an accelerometer and a magnetometer to obtain a coarse attitude matrix; taking a position and a speed error as value measurement by using accurate outside information provided by a GPS (Global Position System); carrying out nonlinear filtering by the quaternion CKF to obtain an attitude error matrix; and finally, correcting by using the attitude error matrix to obtain an accurate attitude matrix. According to the low-precision inertial navigation initial alignment method, the value measurement of the gravitational acceleration and the magnetic force, which is carried out by the accelerometer and the magnetometer, is subjected to the coarse alignment. The problems that the gyroscope performance is low under the condition of a low-precision inertial device, the rotation angle speed of the earth can not be accurately sensed and a traditional coarse alignment method can not be applied are solved; furthermore, the quaternion CKF provided by the method can be used for a non-linear model of a large angle error, can still finish alignment under the condition of a large orientation misalignment angle and has high alignment precision.

Owner:HARBIN ENG UNIV

Method for manufacturing semiconductor device

ActiveUS20050101107A1Reduce in quantityReduced alignment accuracyTransistorSemiconductor/solid-state device detailsEngineeringSilicon oxide

An alignment mark section on a semiconductor substrate has two grooves which are filled with silicon oxide. The surface of the portion of the semiconductor substrate sandwiched by these grooves is lower than other portions of the semiconductor substrate to produce a step having a predetermined depth in the alignment mark section.

Owner:RENESAS ELECTRONICS CORP

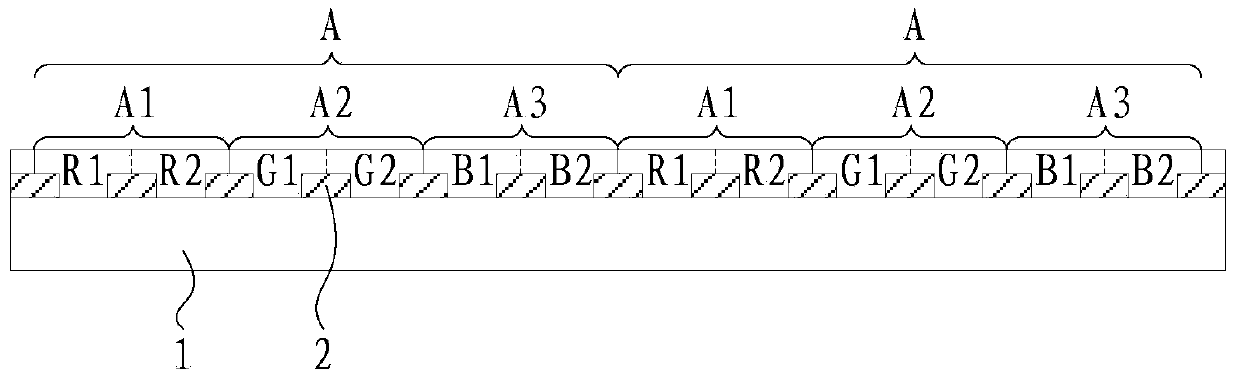

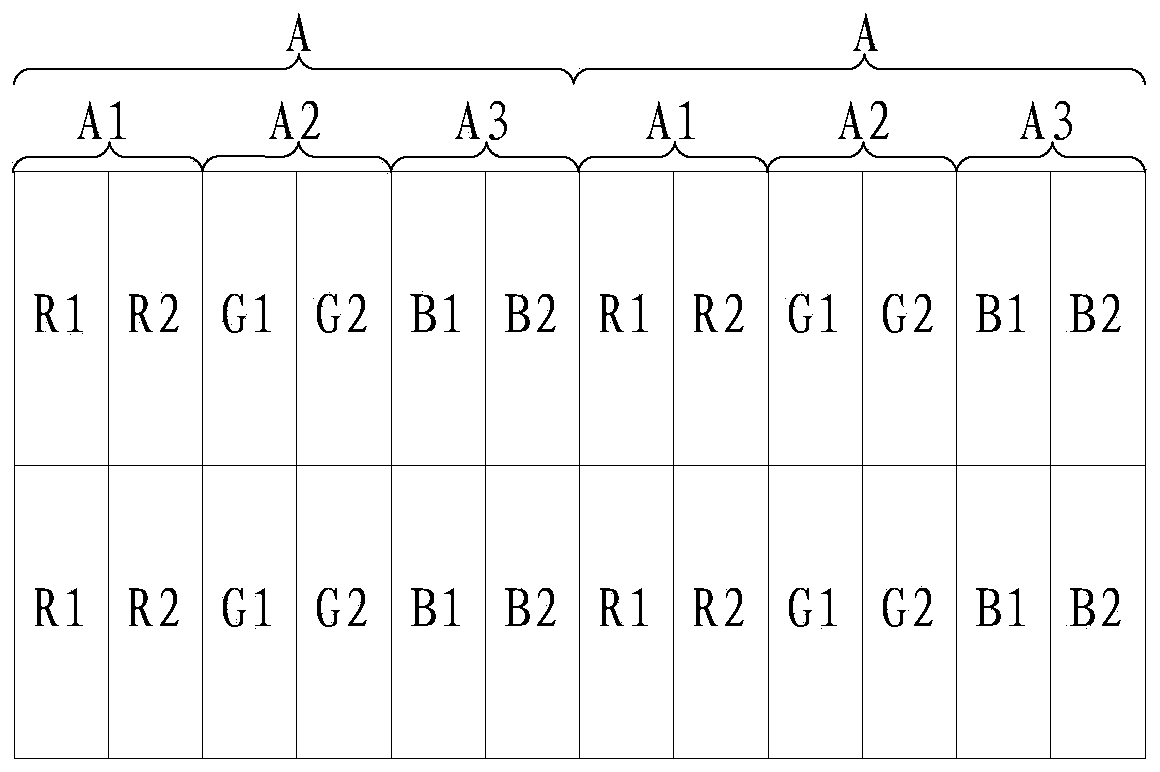

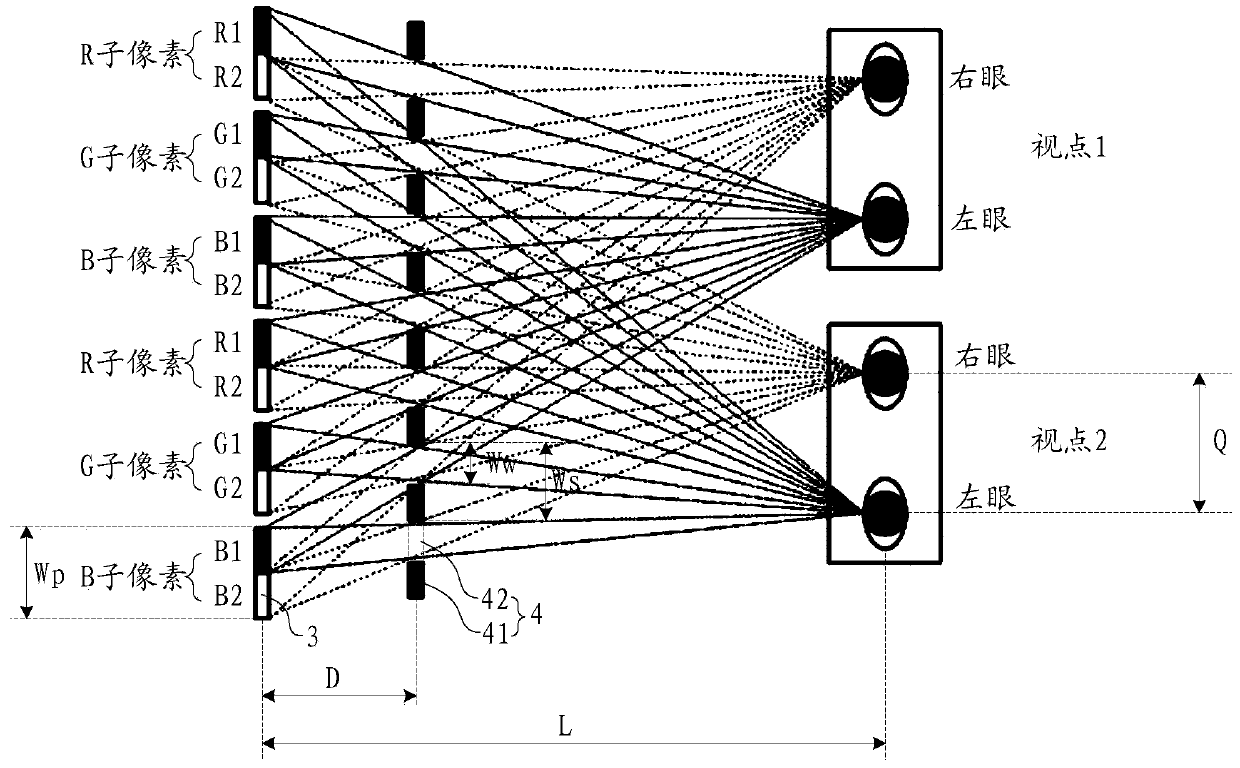

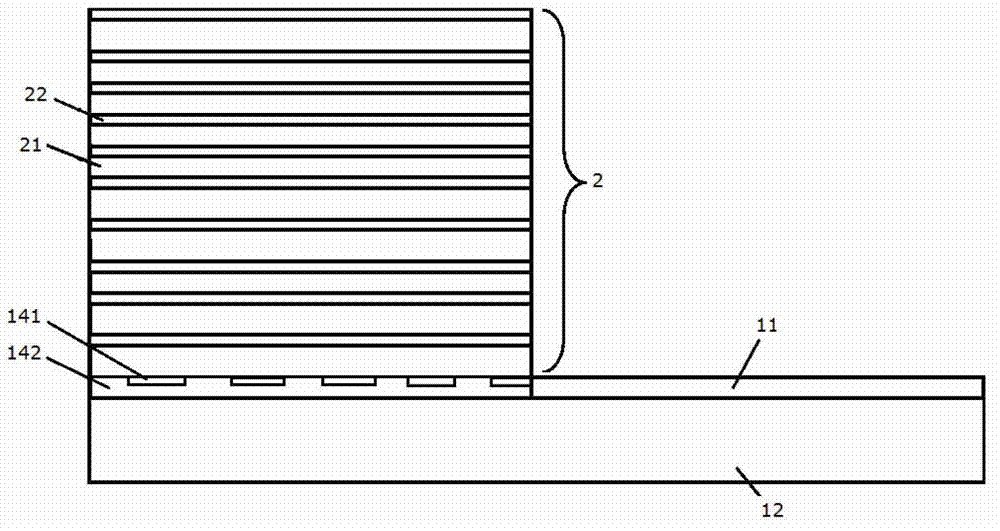

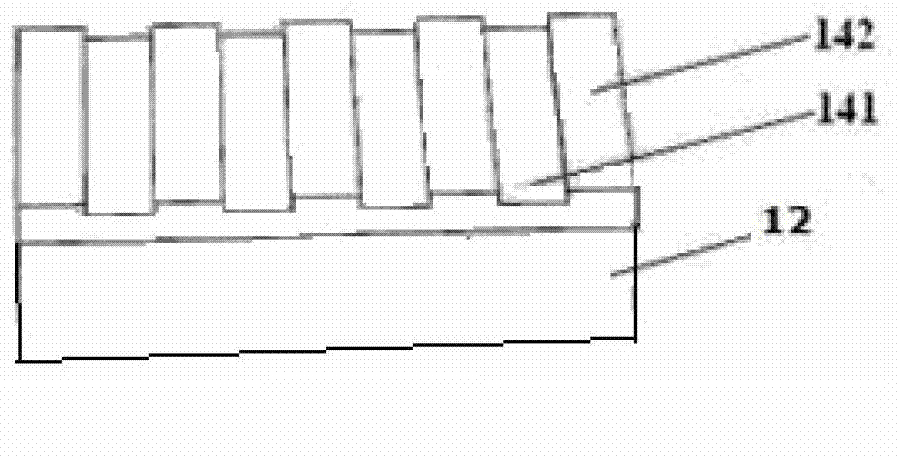

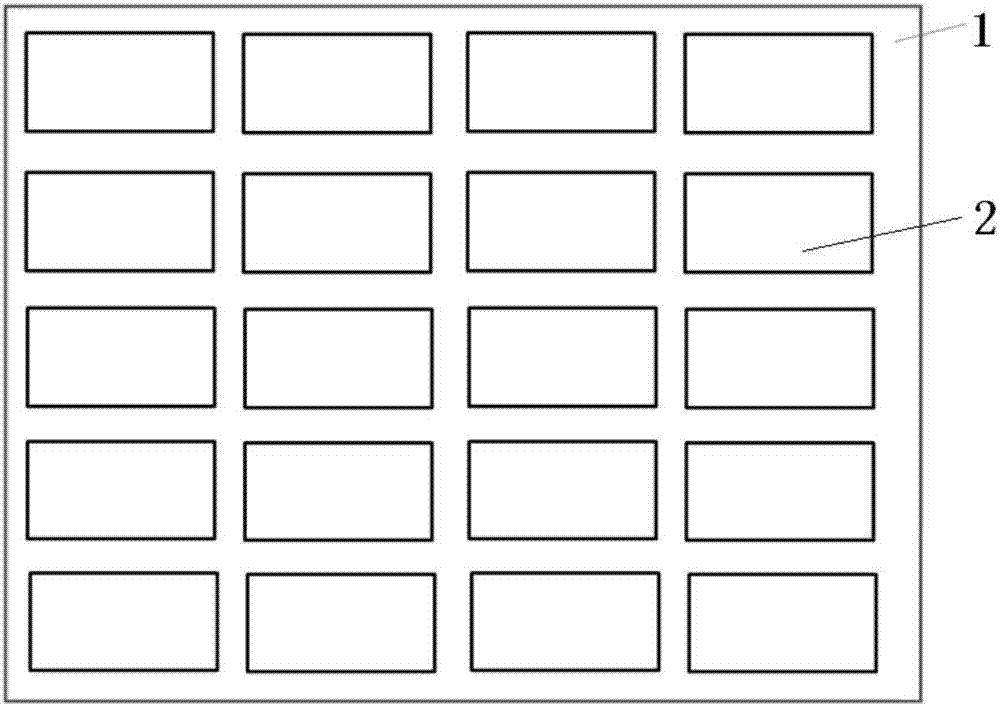

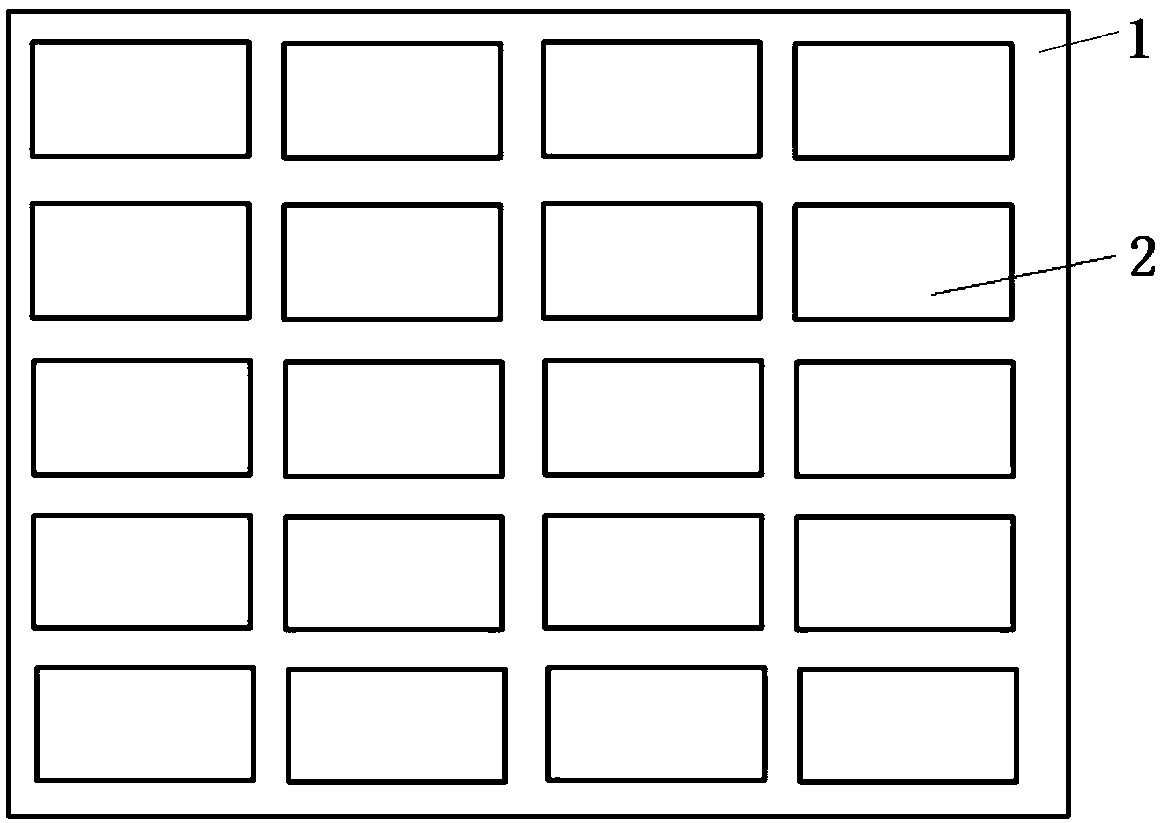

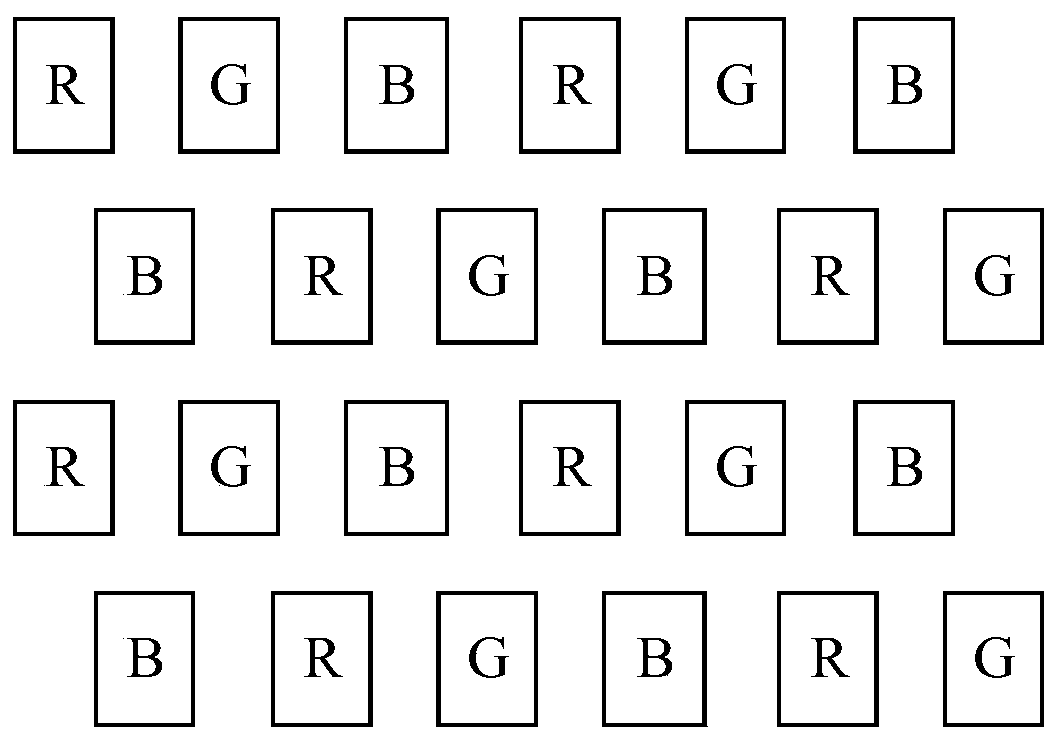

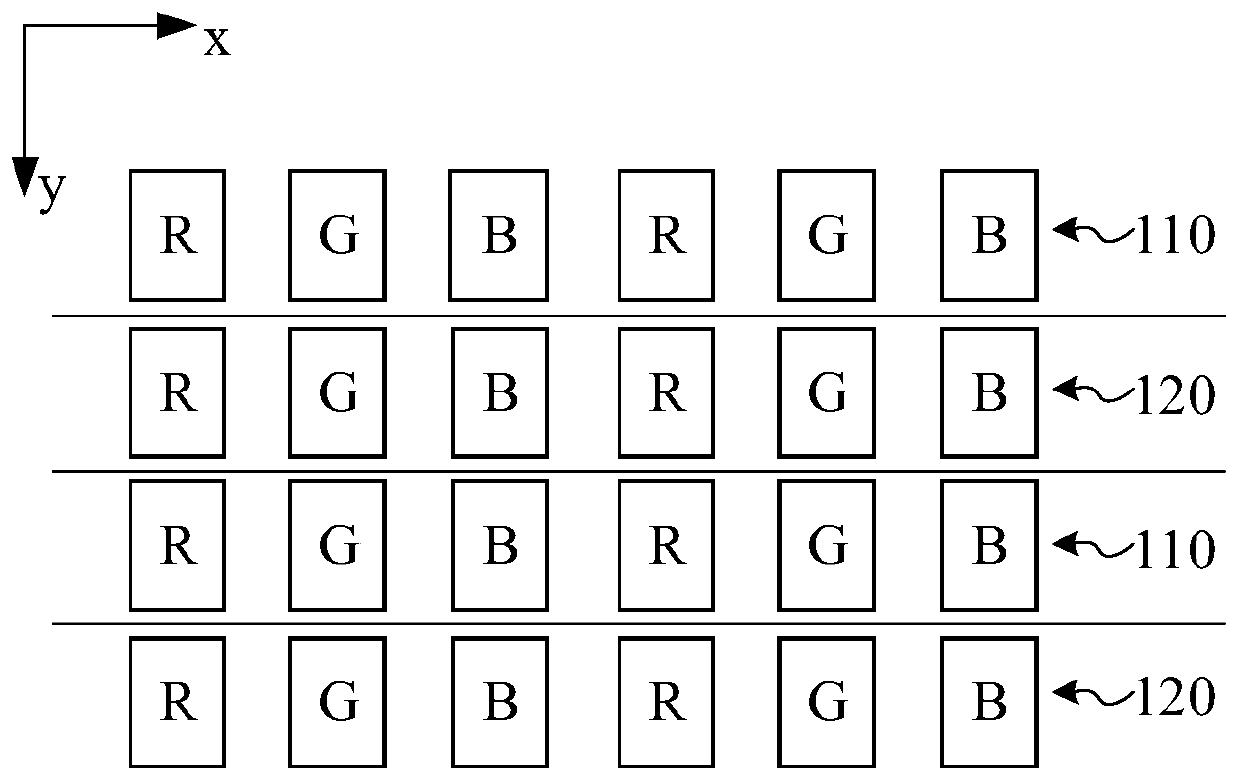

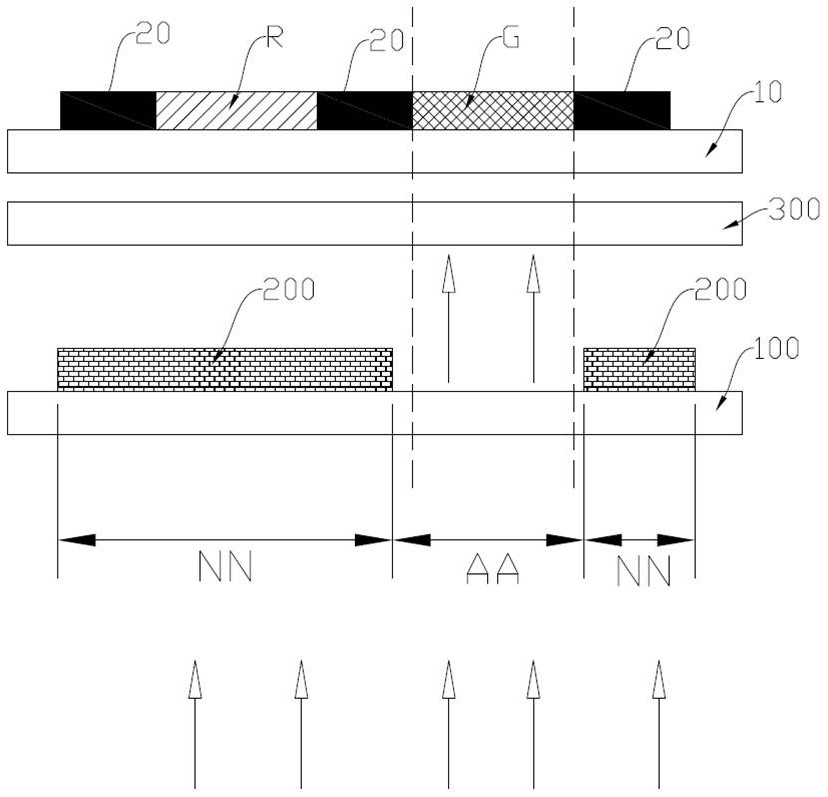

Color filter, color filter manufacturing method, display panel, display device and driving method

ActiveCN104297832AProduction accuracy and alignment accuracy decreaseReduce the difficulty of productionOptical filtersCathode-ray tube indicatorsComputer visionColor filter array

The invention provides a color filter, a color filter manufacturing method, a display panel, a display device and a driving method. The color filter comprises multiple colored color resistors and multiple pixel regions, wherein the multiple colored color resistors include the red color resistors, the green color resistors and the blue color resistors, the multiple pixel regions are arranged in a matrix mode, each pixel region comprises a red sub-pixel region, a green sub-pixel region and a blue sub-pixel region, each red sub-pixel region comprises red inferior sub-pixel regions, the number of the red inferior sub-pixel regions of each red sub-pixel region is an even number, one red color resistor is arranged in each red inferior sub-pixel region, each green sub-pixel region comprises green inferior sub-pixel regions, the number of the green inferior sub-pixel regions of each green sub-pixel region is an even number, one green color resistor is arranged in each green inferior sub-pixel region, each blue sub-pixel region comprises blue inferior sub-pixel regions, the number of the blue inferior sub-pixel regions of each blue sub-pixel region is an even number, and one blue color resistor is arranged in each blue inferior sub-pixel region. Compared with the prior art, the manufacturing precision of a mask plate required by the color filter is lowered, the alignment precision is lowered, and the manufacturing difficulty of the color filter is lowered.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

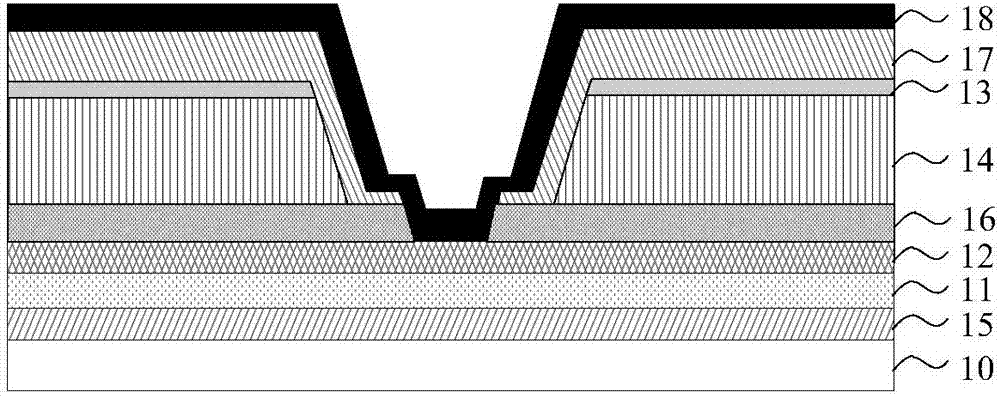

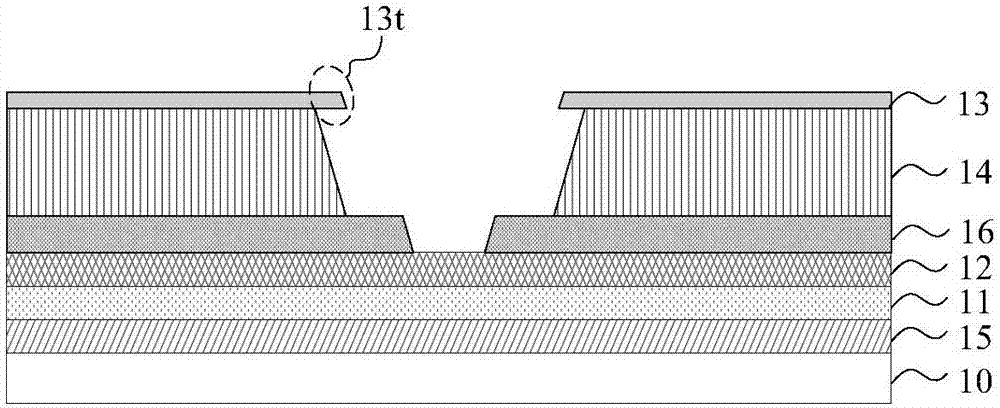

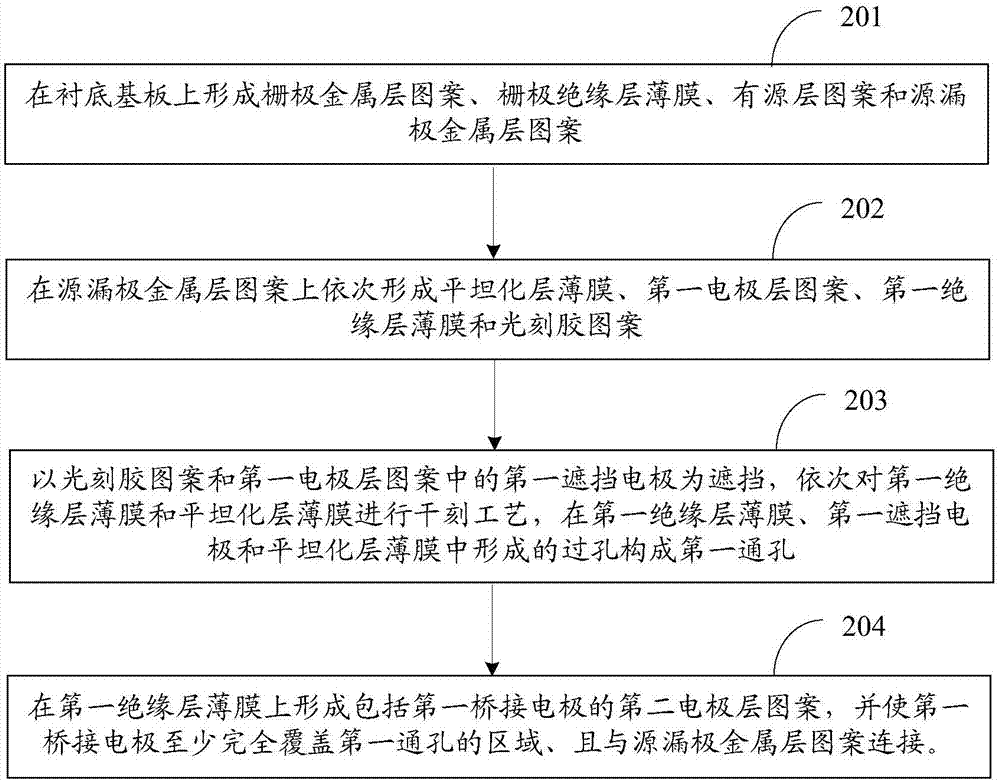

Array substrate and manufacturing method therefor and display apparatus

ActiveCN107316839AMeet etching requirementsIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingPhotolithographyEngineering

The invention relates to an array substrate and a manufacturing method therefor and a display apparatus, and aims to solve the problem of a relatively complex manufacturing process of a TFT substrate, so that an effective mode for reducing photolithography techniques without lowering product yield is needed urgently. The manufacturing method comprises the steps of forming a gate metal layer pattern, a gate insulating layer thin film, an active layer pattern and source and drain metal layer patterns on a substrate; forming a planarization layer thin film, a first electrode layer pattern, a first insulating layer thin film and a photoresist pattern on the source and drain metal layer patterns in sequence; performing a dry etching process on the first insulating layer thin film and the planarization layer thin film in sequence, wherein via holes formed in the first insulating layer thin film, a first shielding electrode and the planarization layer thin film form a first through hole; and forming a second electrode layer pattern which comprises a first bridging electrode on the first insulating layer thin film, and enabling the first bridging electrode to at least fully cover the first through hole region and to be connected with the source and drain metal layer patterns.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

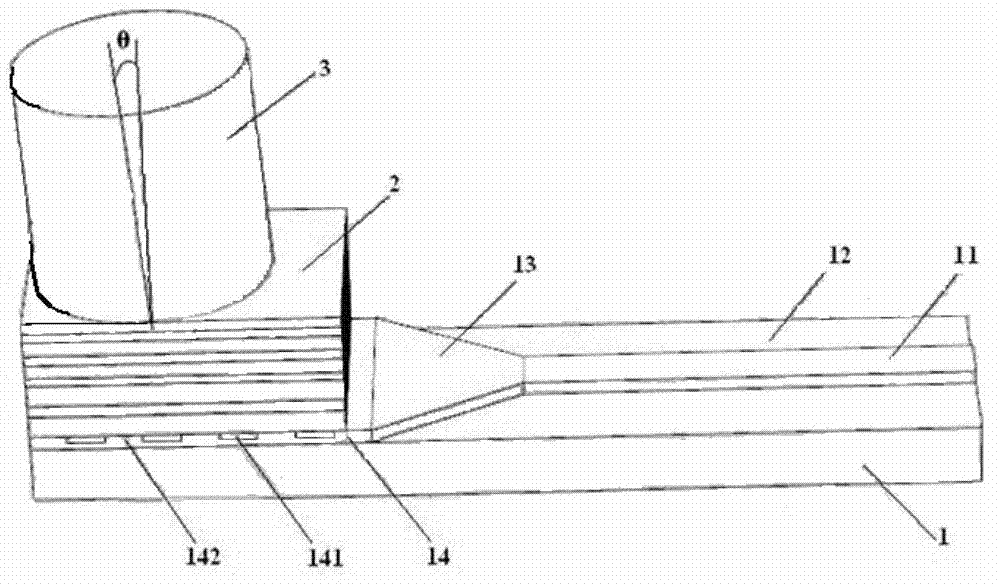

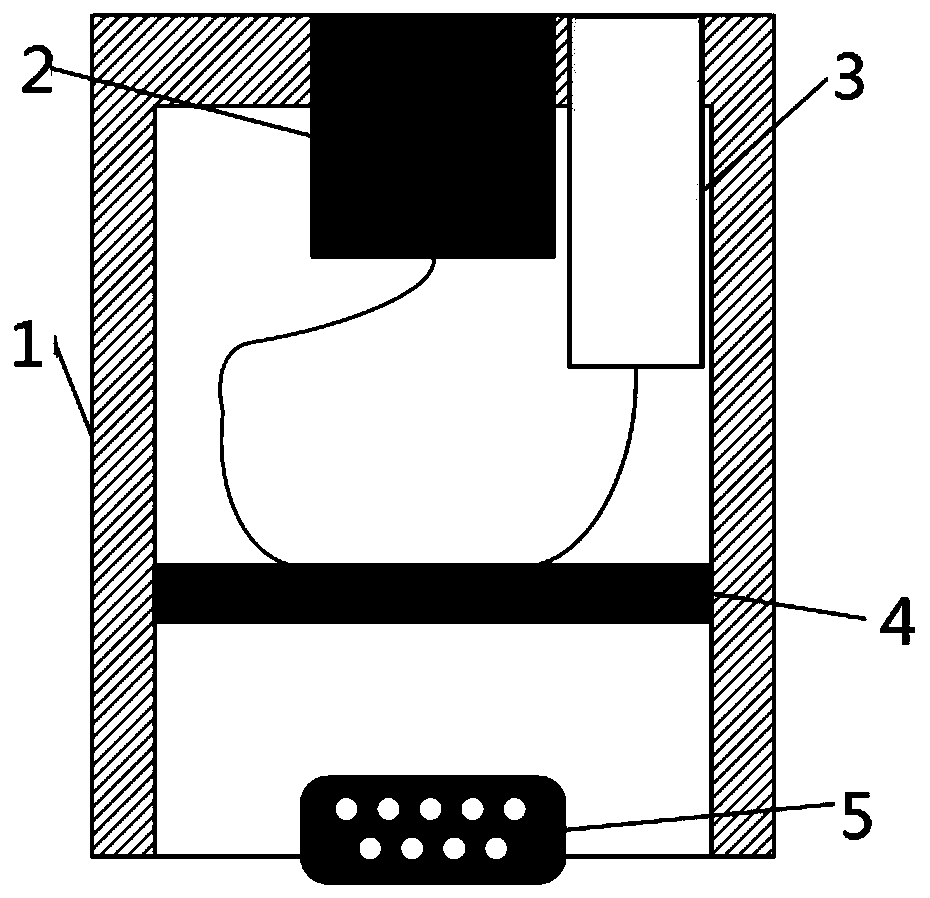

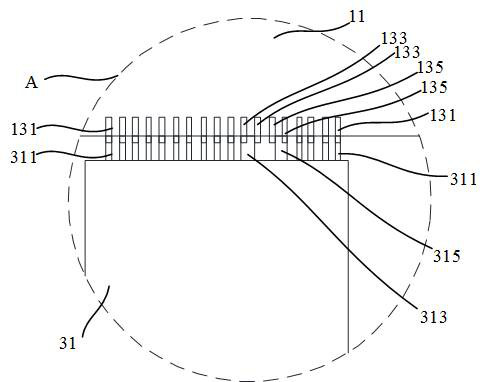

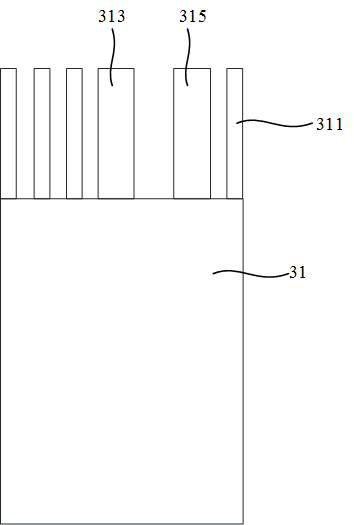

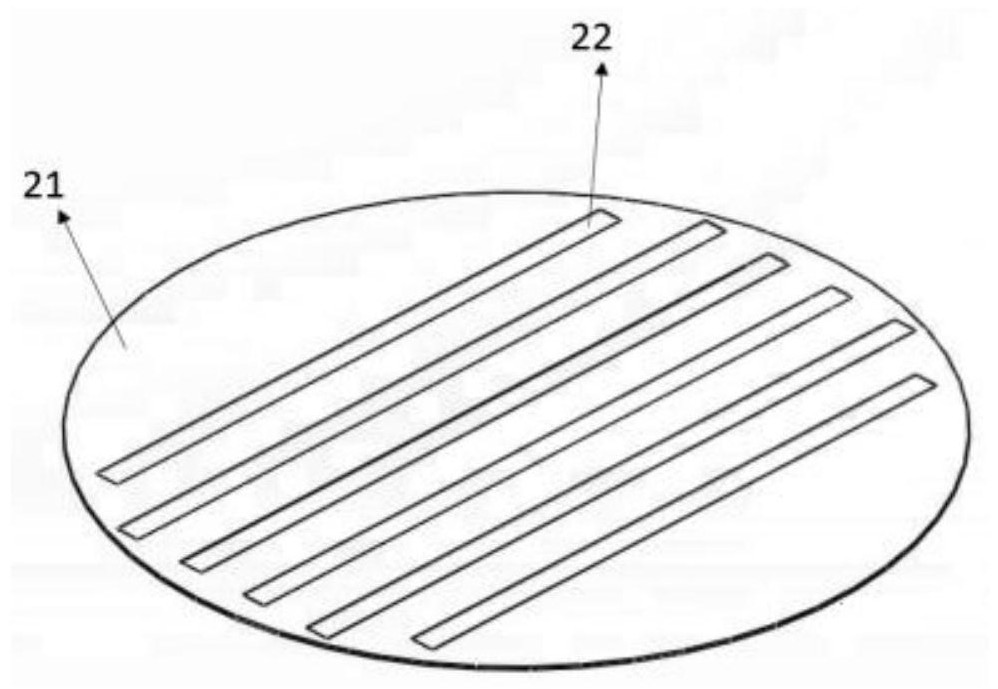

On-chip periodic variation refractive index lens photon chip three-dimensional coupler and preparation method thereof

InactiveCN103033881AEasy to integrateReduced alignment accuracyCoupling light guidesOptical waveguide light guideGratingLow demand

The invention discloses an on-chip periodic variation refractive index lens photon chip three-dimensional coupler. The coupler comprises a photon chip, a periodic variation refractive index lens layer and an optical fiber, wherein the photon chip comprises a silicon substrate, and a ridge waveguide, an analogue-spot converter and a grating which grow and are etched on the top surface of the silicon substrate; an input port of the analogue-spot converter is equal to the ridge waveguide in width, and is connected with a waveguide port of the ridge waveguide; an output port of the analogue-spot converter is equal to the grating in width, and is connected with an input port of the grating; the periodic variation refractive index lens layer is connected to the top surface of the grating; and the optical fiber is connected to the top surface of the periodic variation refractive index lens layer. The coupler has the advantages of small size, convenience for integration, strong optical field restraint and low demand to the aligning precision, and can achieve efficient and quick coupling between the chip and the optical fiber. And at the same time, the invention further discloses a preparation method for the coupler; and the preparation method is simple and feasible.

Owner:SOUTHEAST UNIV

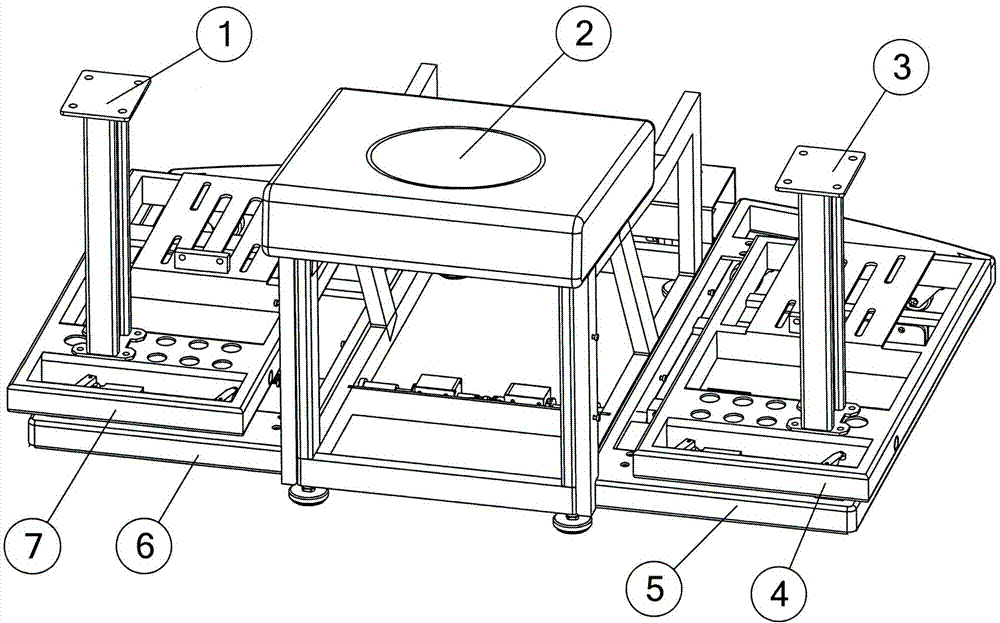

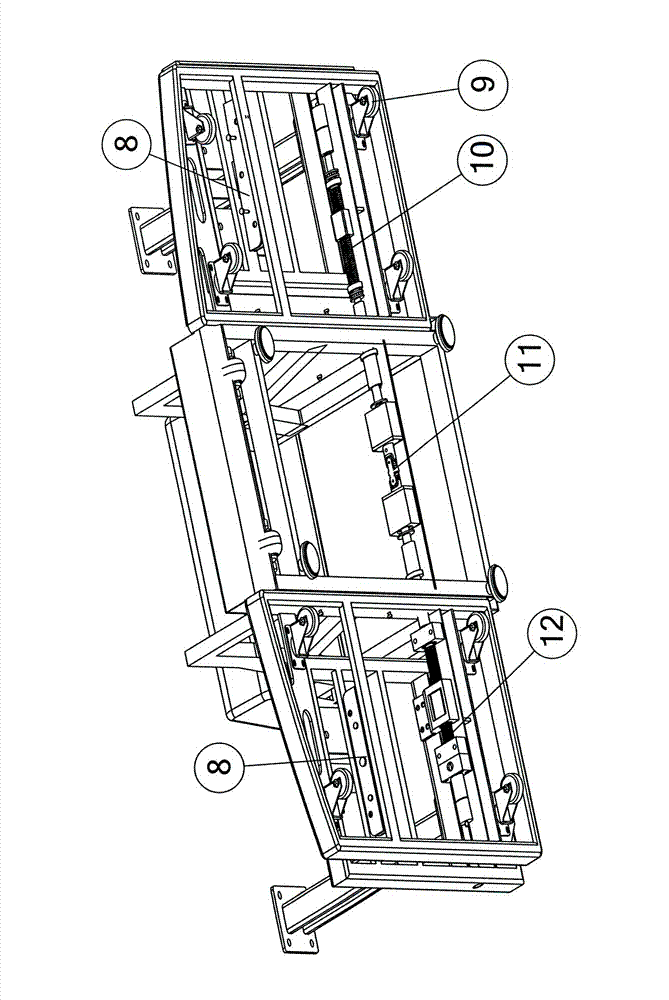

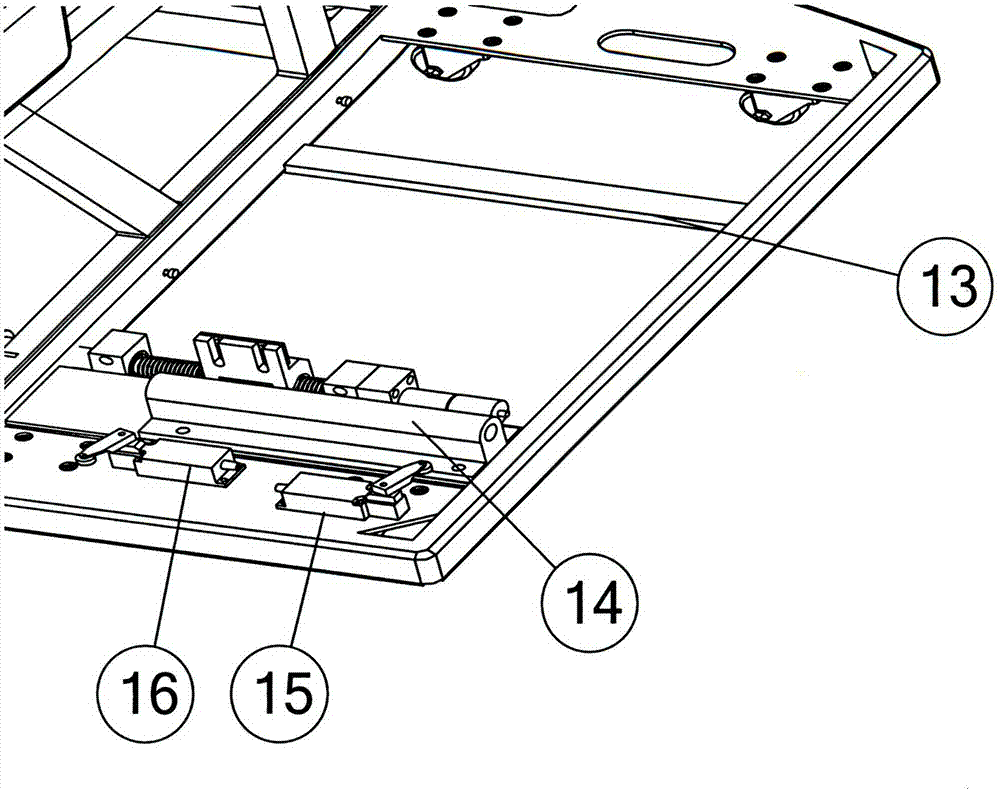

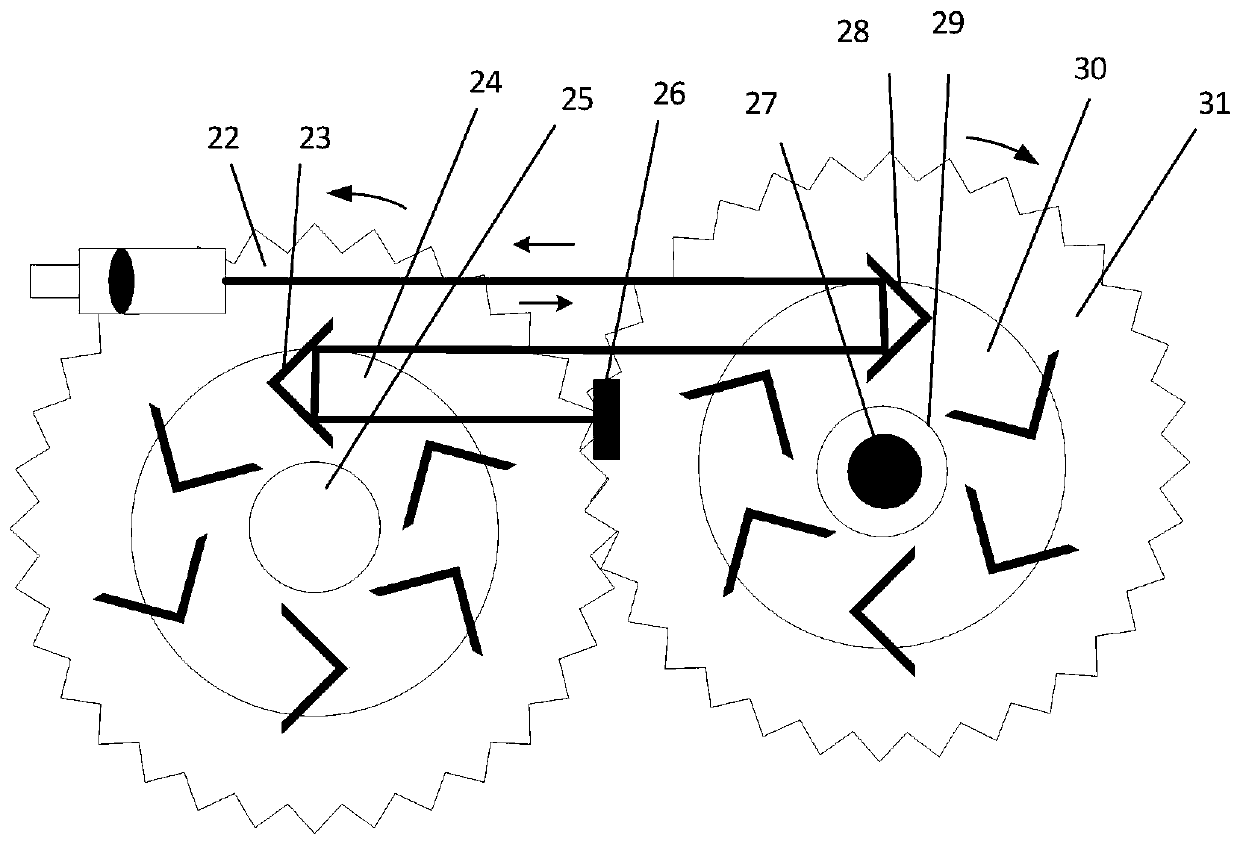

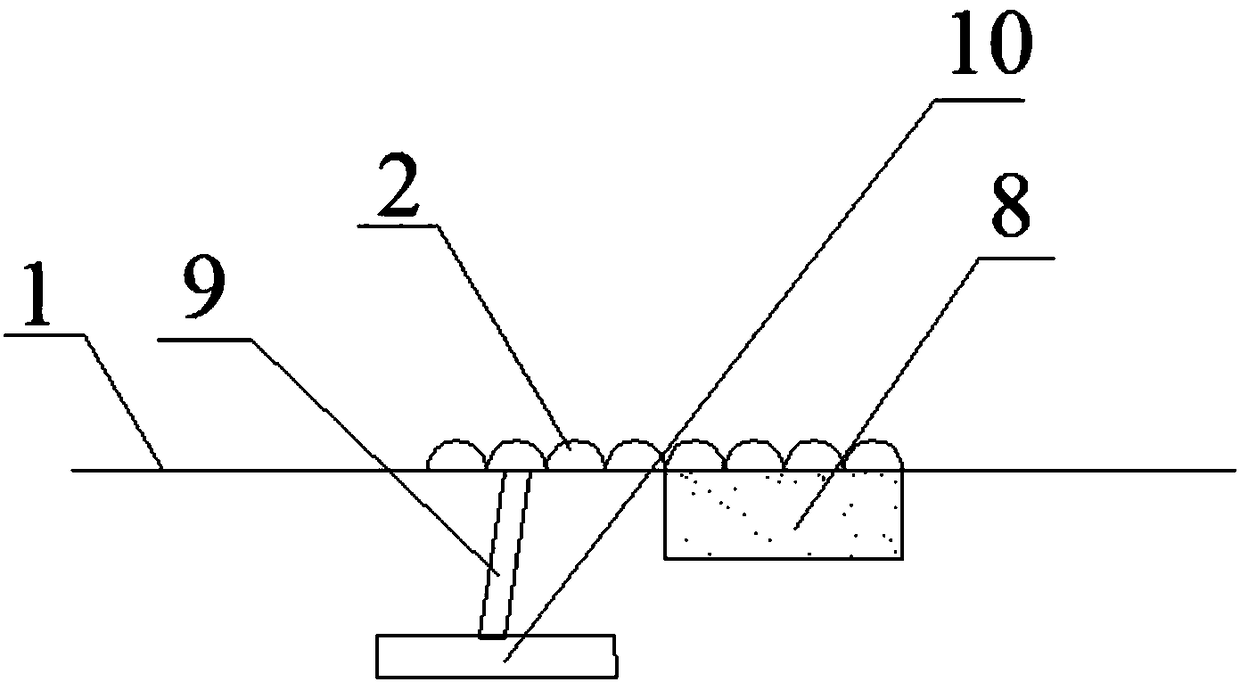

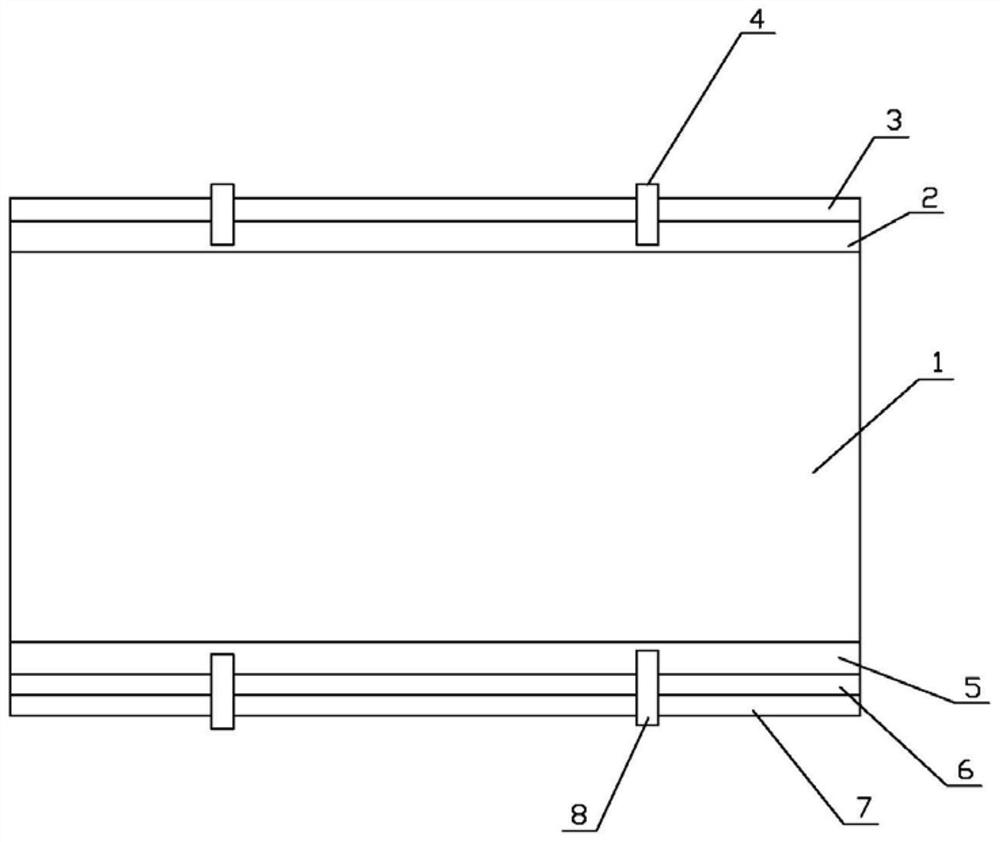

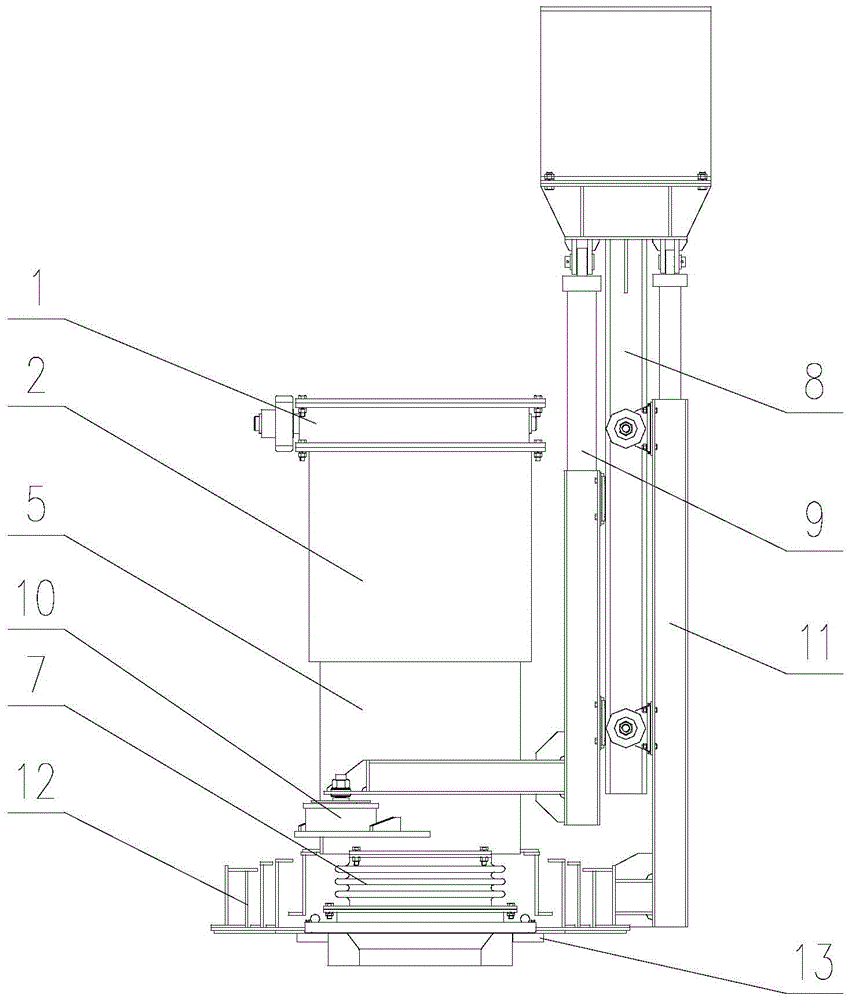

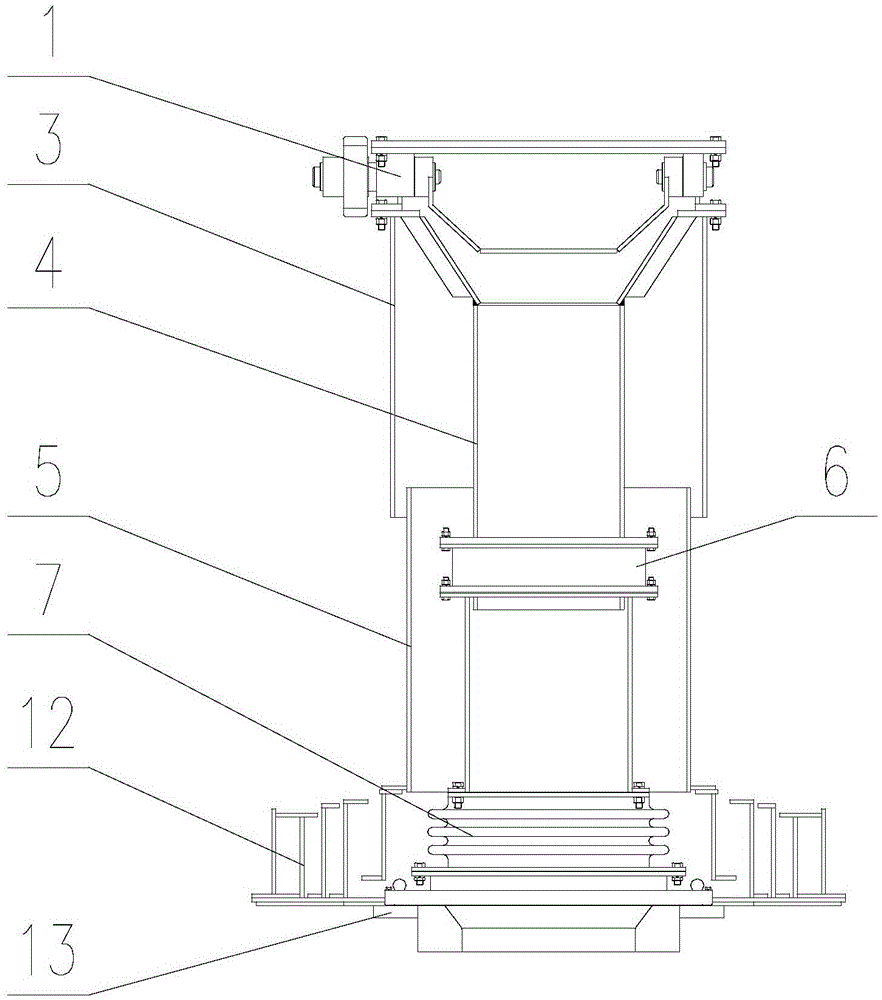

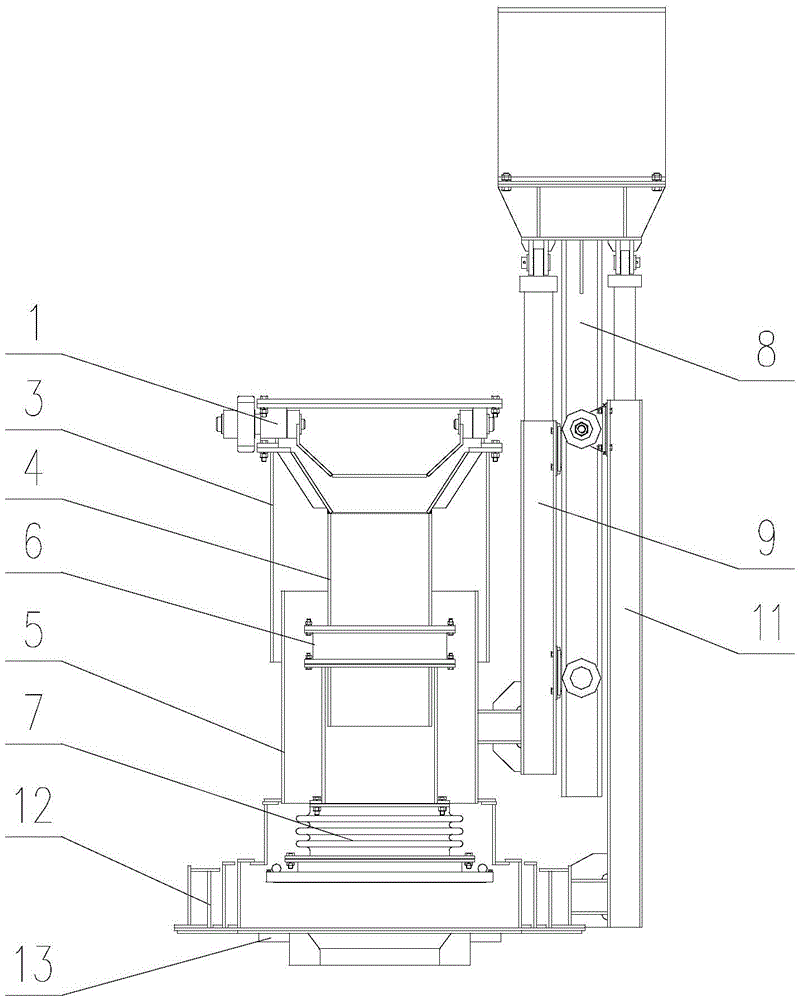

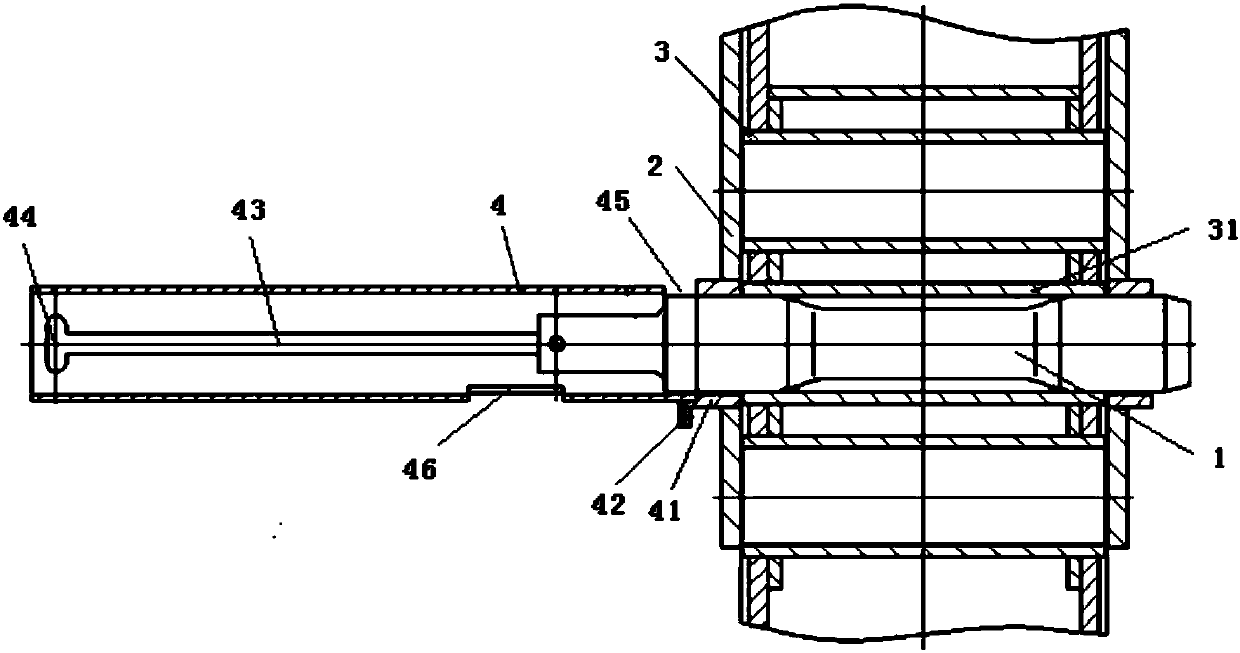

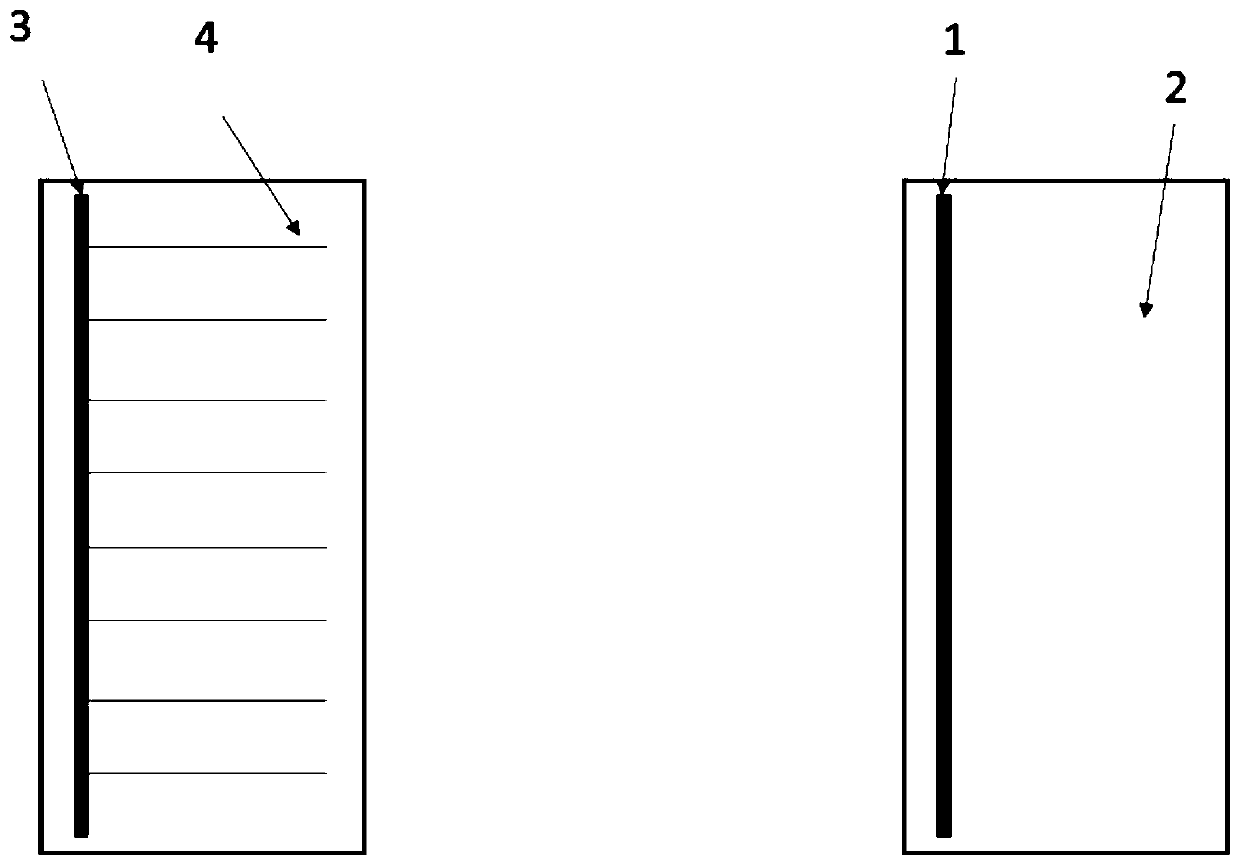

Width-adjustable base for lower limb rehabilitation robot

The invention discloses a width-adjustable base suitable for installation of a sitting and lying type lower limb rehabilitation robot, and the width-adjustable base is medical treatment rehabilitation auxiliary equipment used for training and treatment of lower limb paralysis / paraplegia patients. The width-adjustable base consists of a left-side base 1, a right-side base 3 and a seat 2, wherein the left-side base 1 and the right-side base 3 are respectively installed on two sides of the seat 2; the right-side base 3 is composed of an upper-layer movable base 4, a lower-layer fixed base 5 and a right transmission mechanism 12, the left-side base 1 is composed of an upper-layer movable base 7, a lower-layer fixed base 6 and a left transmission mechanism 10, the left and right transmission mechanisms 10 and 12 are linked via a universal coupling 11, the universal coupling 11 is linked and fixedly installed at the bottom of the seat 2 through bearing blocks 27 and 28, a right-side lead screw 24 is linked with the universal coupling 11 under the seat 2 through a jaw clutch 26.

Owner:YANSHAN UNIV

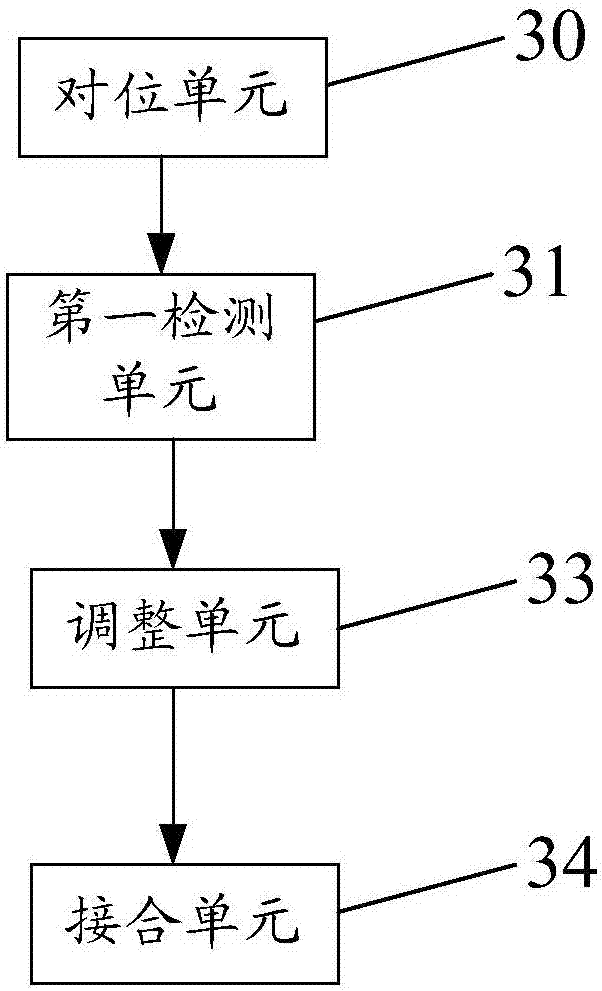

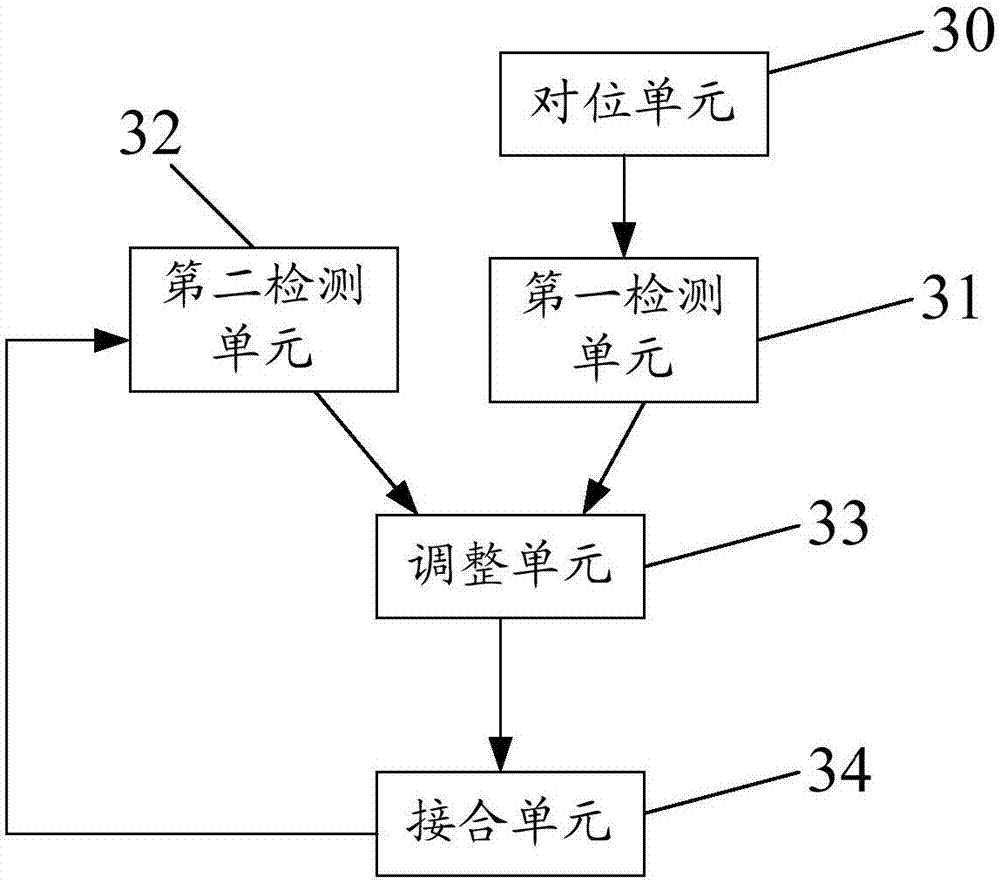

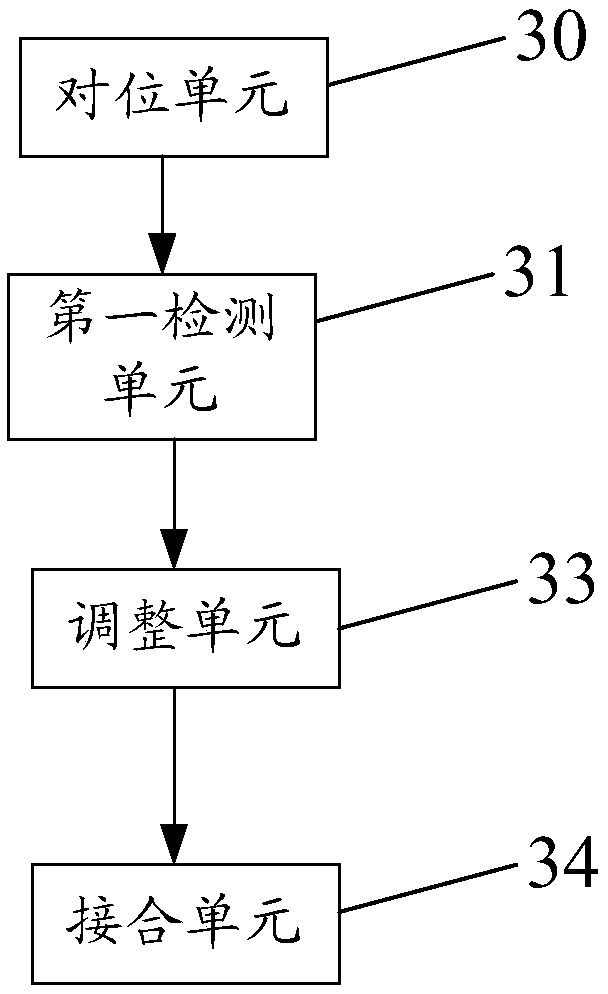

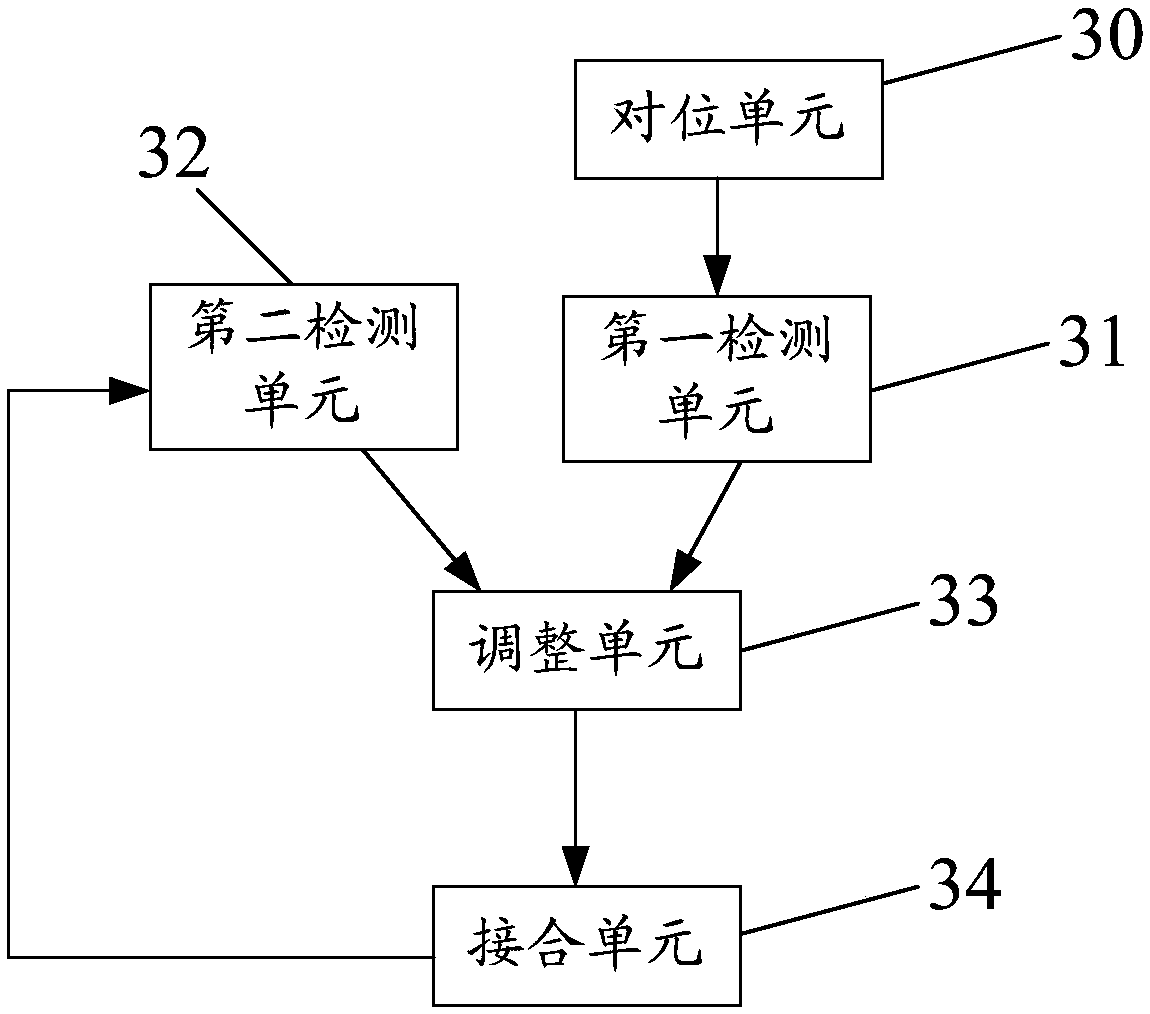

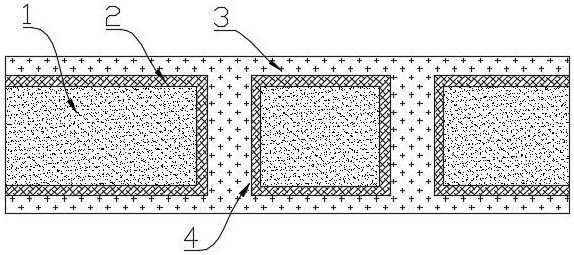

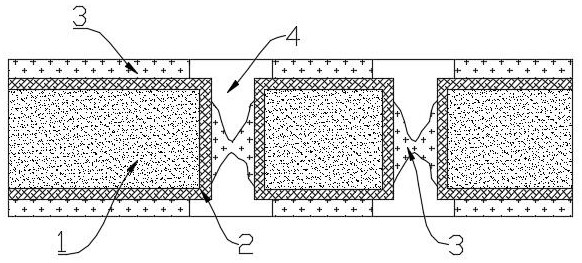

Mask strip connection method and device as well as mask plate

ActiveCN107201498ADoes not affect the fixing accuracyShorten the timeVacuum evaporation coatingSputtering coatingEngineeringProcess time

The invention provides a mask strip connection method and device as well as a mask plate, belongs to the technical field of display, and aims to solve the problems that the overall mask plate formed by welding mask strips is long in alignment process time consumption and low in alignment precision. According to the mask strip connection method and device as well as the mask plate, the positional deviation of a frame after alignment is taken as first compensation data to compensate for the pixel coordinate basis, so that the difference between the actual position of the mask strip frame and the target position is set within a wider range, the mask strip frame at the level can fall into the threshold range of the alignment precision within a shorter time, the alignment time is greatly reduced, the alignment process is prevented from entering the dead circulation, and the production efficiency is improved while the fixed connection precision of the mask strips of the mask plate is not affected.

Owner:BOE TECH GRP CO LTD +1

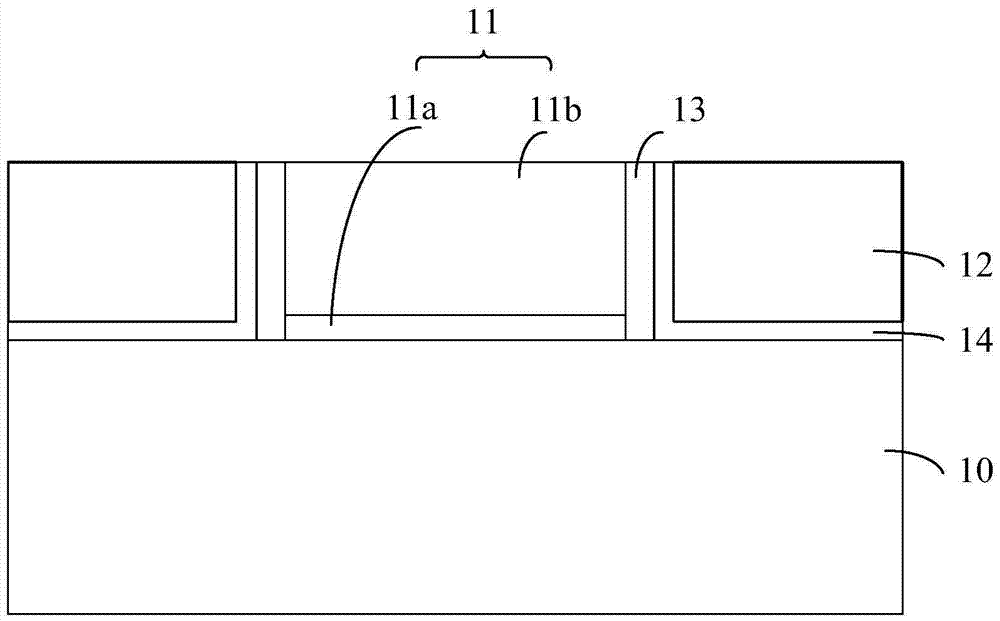

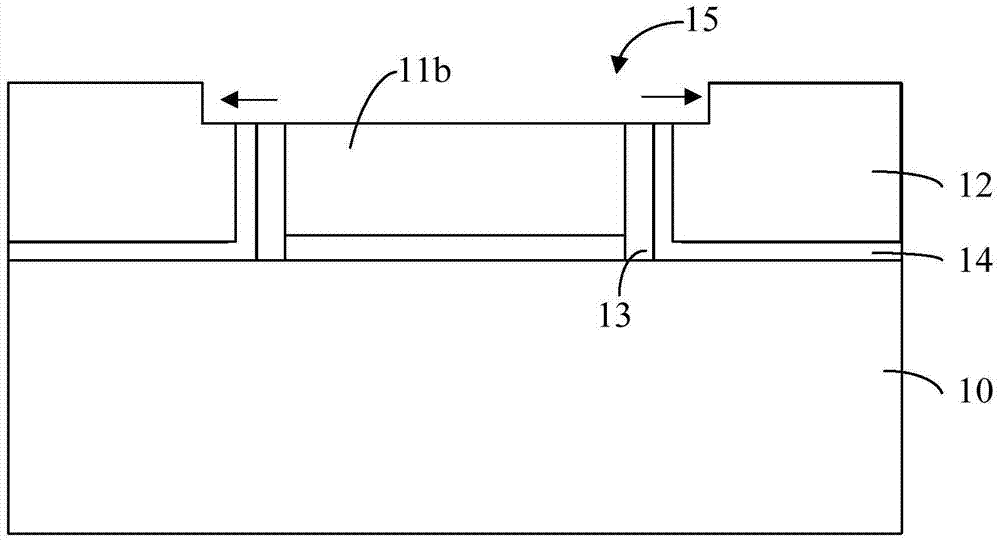

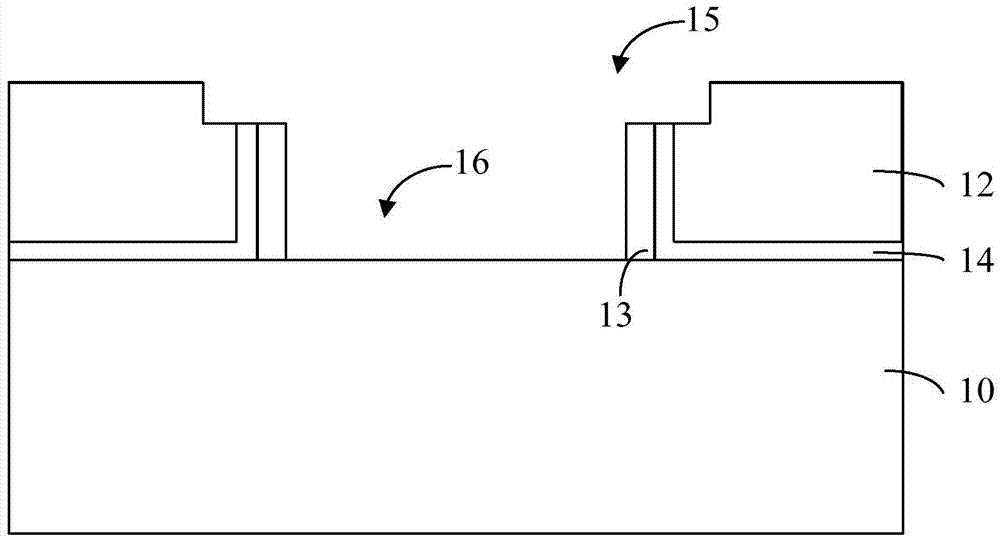

Manufacturing method for source and drain region contact plug of metal gate transistor

ActiveCN106920750AImprove device yieldReduced alignment accuracySolid-state devicesSemiconductor/solid-state device manufacturingWork functionFineness

Disclosed is a manufacturing method for a source and drain region contact plug of a metal gate transistor. a) for a technology of high K gate dielectric layer last and metal gate first, and in a process of removing a pseudo gate structure and filling in a high K gate dielectric layer, a work function layer and a metal gate, and b) for a technology of high K gate dielectric layer first and metal gate last, and in a process of removing a pseudo gate and filling in a work function layer and a metal gate, an etching barrier layer is formed on the metal gate structure, wherein the two ends of the etching barrier layer are both wider than the metal gate structure. By virtue of the etching barrier layer, even if alignment between a mask plate and a substrate has deviation or even if an opening, corresponding to a through hole, in the mask plate is relatively large, in a photoetching technology of forming a contact through hole in the source and drain regions in a dielectric layer subsequently, the through hole formed by etching does not expose the metal gate due to protection of the etching barrier layer on the covered metal gate structure and dielectric layer below the etching barrier layer; and therefore, a conductive materiel arranged in the through hole in a filling way is not in electrical conduction with the metal gate, so that the yield of a device is improved, the alignment precision between the mask plate and the substrate is lowered, and the requirement on the photoetching fineness is lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

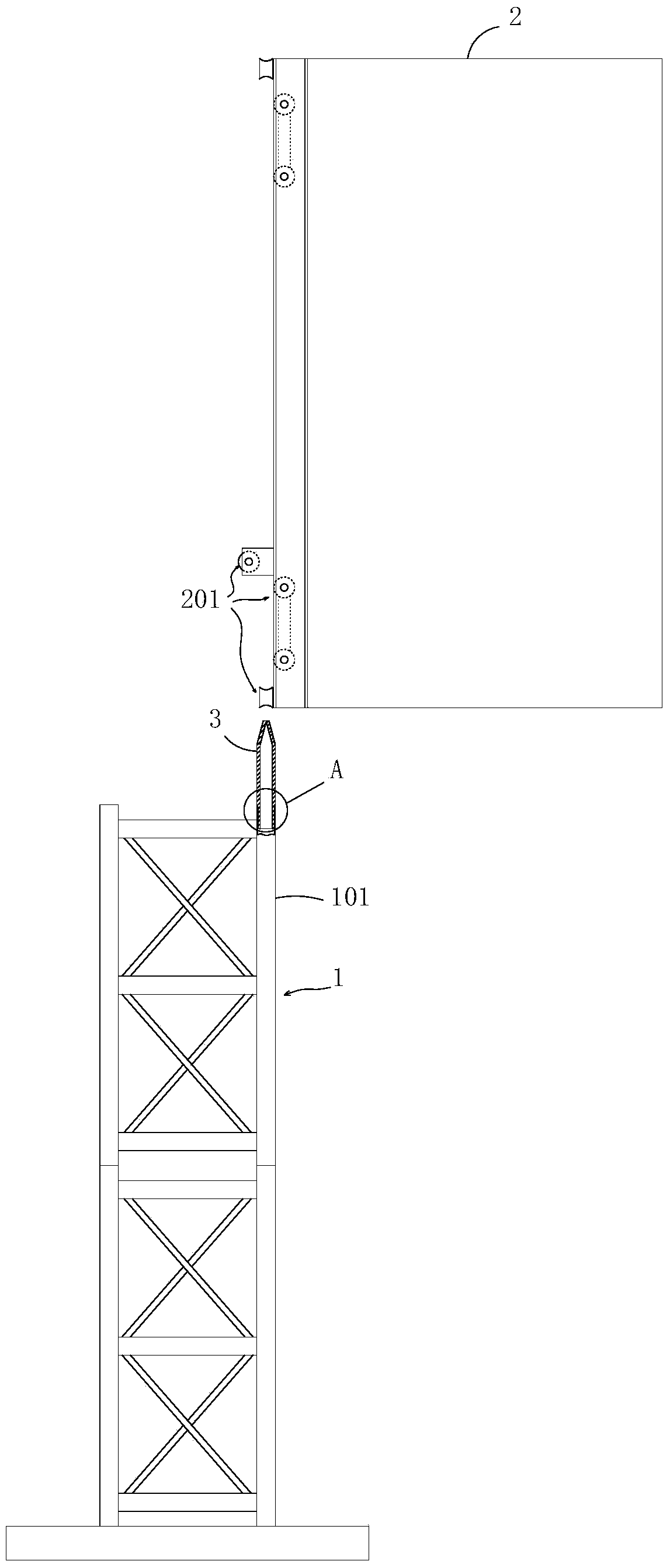

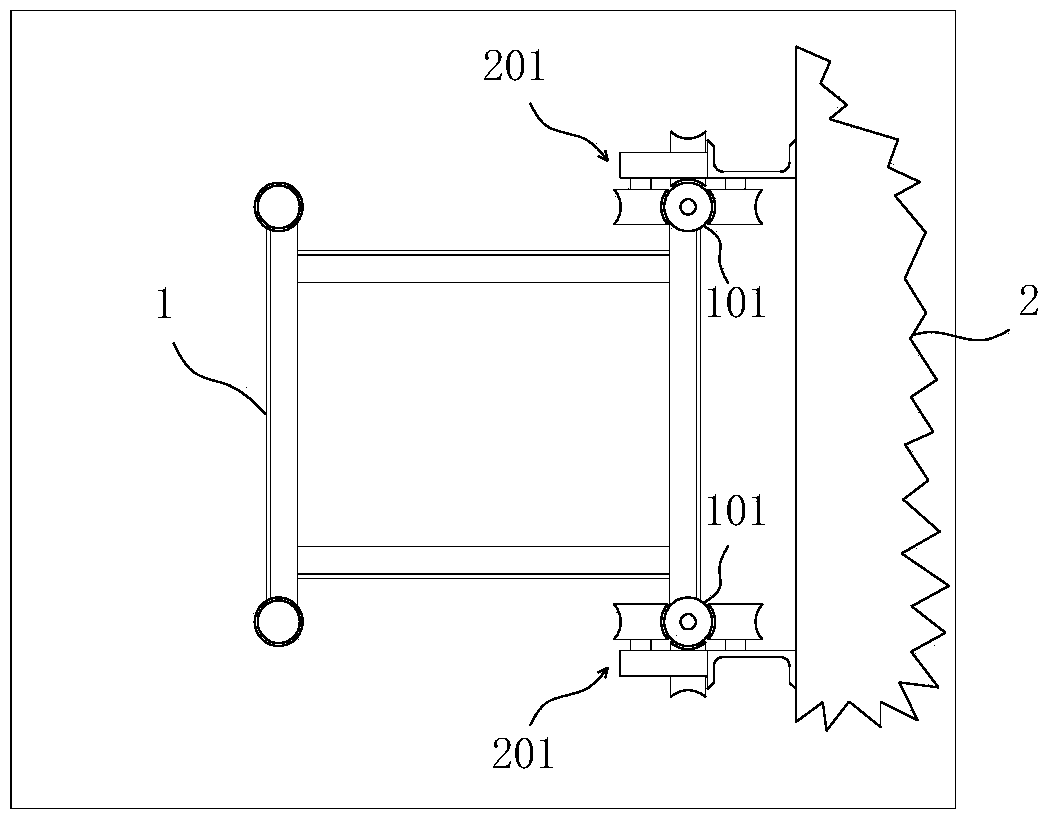

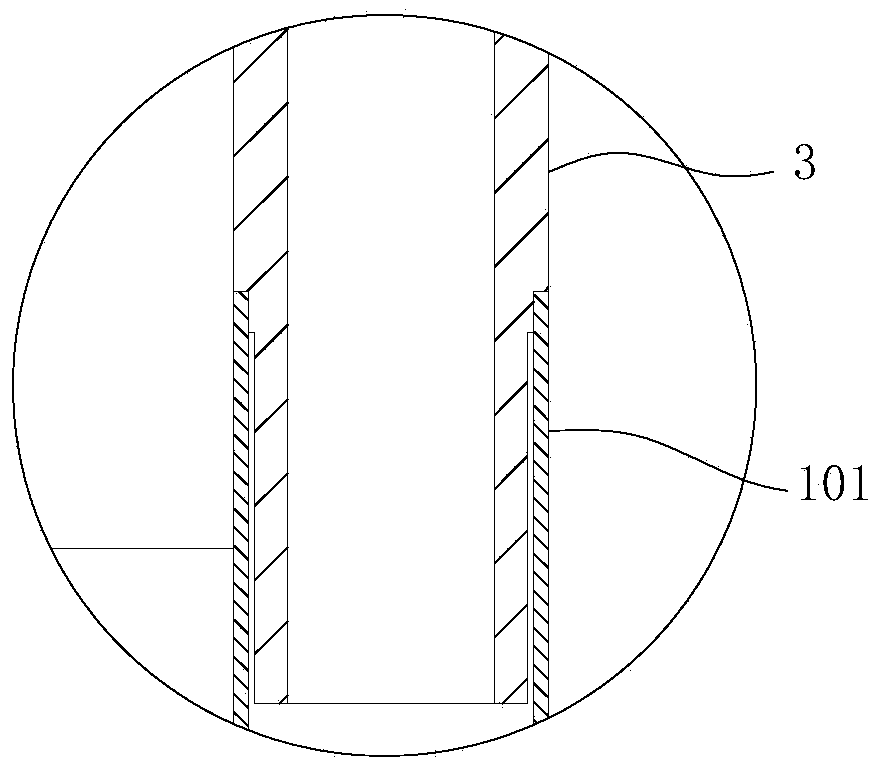

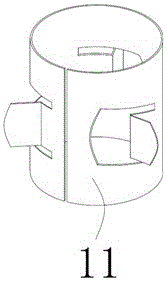

Guide device for safely locating construction hoist cage and installation method for cage

ActiveCN103626009ALess difficult to seatReduced alignment accuracyElevatorsMetal working apparatusArchitectural engineeringBuilding construction

The invention discloses a guide device for safely locating a construction hoist cage and an installation method for the cage. The guide device facilitates installation of the cage and solves the problem of potential safety hazards. The guide device comprises a cylindrical body formed by an upper portion guide section, a middle guide section and a lower portion locating section, wherein the upper portion guide section, the middle guide section and the lower portion locating section are coaxially arranged. The upper portion guide section of the cylindrical body is of a cone-shaped guide structure. The middle guide section is matched with a guide porthole formed by a guide wheel set of the construction hoist cage. The lower portion locating section is matched with an upper pipe orifice of a standard-knot stand column of a construction hoist. After the lower portion locating section extends into the pipe cavity of the stand column, a side gap is formed between the lower portion locating section and the inner pipe wall of the pipe cavity and enables the cylindrical body to deflect at the upper end of the stand column in a small-angle mode. The diameter of the lower portion locating section is smaller than that of the middle guide section, so that a locating step used for being meshed with the end face of the upper pipe orifice is formed on the joint portion of the middle guide section and the lower portion locating section. By means of the guide device, the location difficulty of the cage is lowered, and the danger such as pinching of hands can be avoided.

Owner:成都建工第二建筑工程有限公司

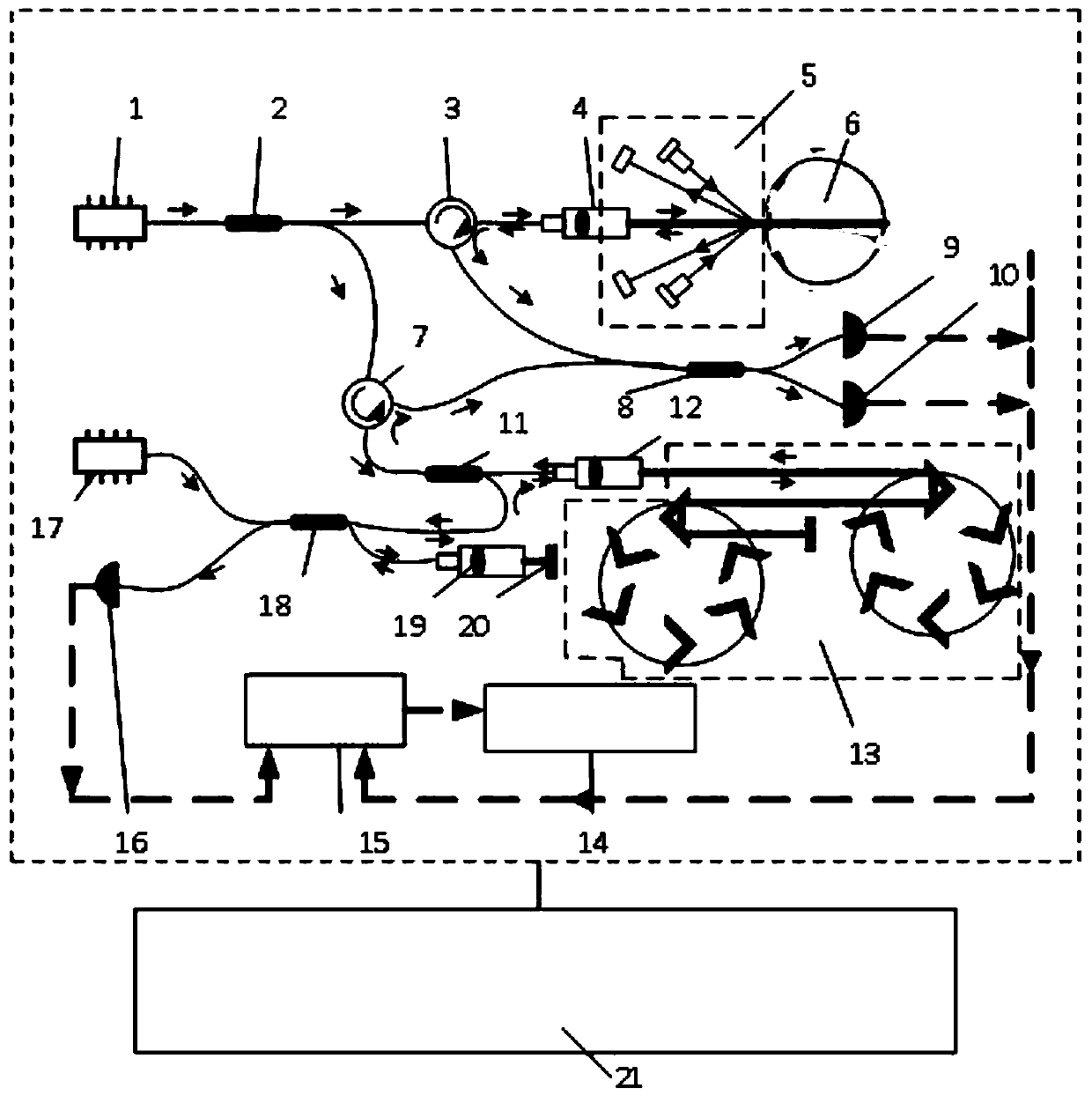

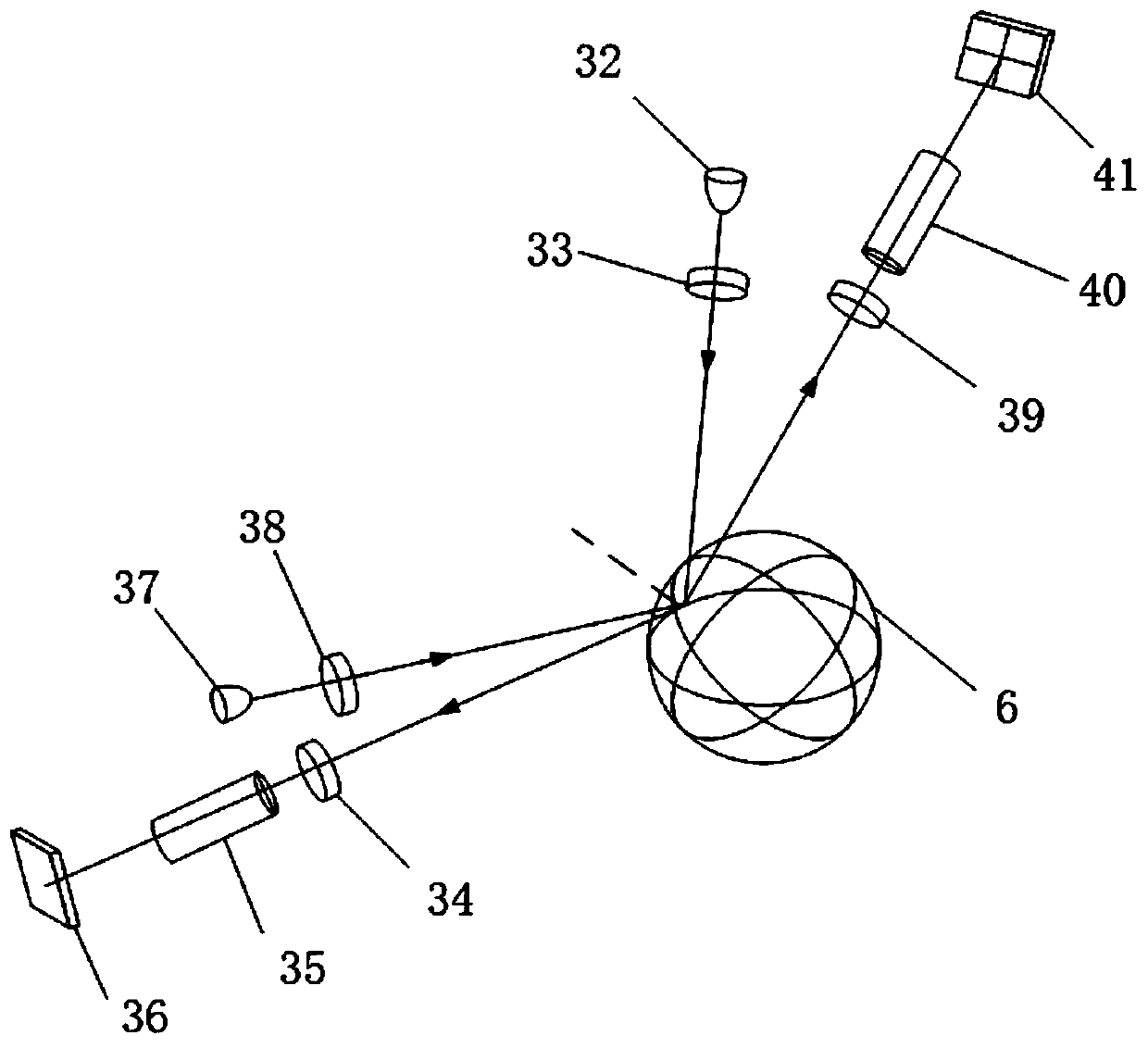

Optical fiber type rapid measuring system for eyeball axial multiparameter

ActiveCN110169752AAccurate measurementPrecise positioningGonioscopesSignal-to-noise ratio (imaging)Mach–Zehnder interferometer

The invention relates to an optical fiber type rapid measuring system for eyeball axial multiparameter, and belongs to the technical field of measurement applying optical instruments to ophthalmology.The system is composed of a set of low coherent systems integrated on a triaxial mobile platform, a set of high coherent systems and an eyeball aligning system; two sets of optical fiber interferencesystems are constructed to realize measuring requirements; the high coherent systems are a Mach Zehnder interferometer; low coherent signals are used to perform accurate positioning on different tissue interfaces of eyeball axial direction; the high coherent systems are a Michelson interferometer; uniform high coherent signals are used as metering scales for performing distance measurement on thelow coherent signals. The system has the advantages of non-contact measurement, rapid measuring speed, high accuracy, high signal-to-noise ratio, high eyeball alignment accuracy and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

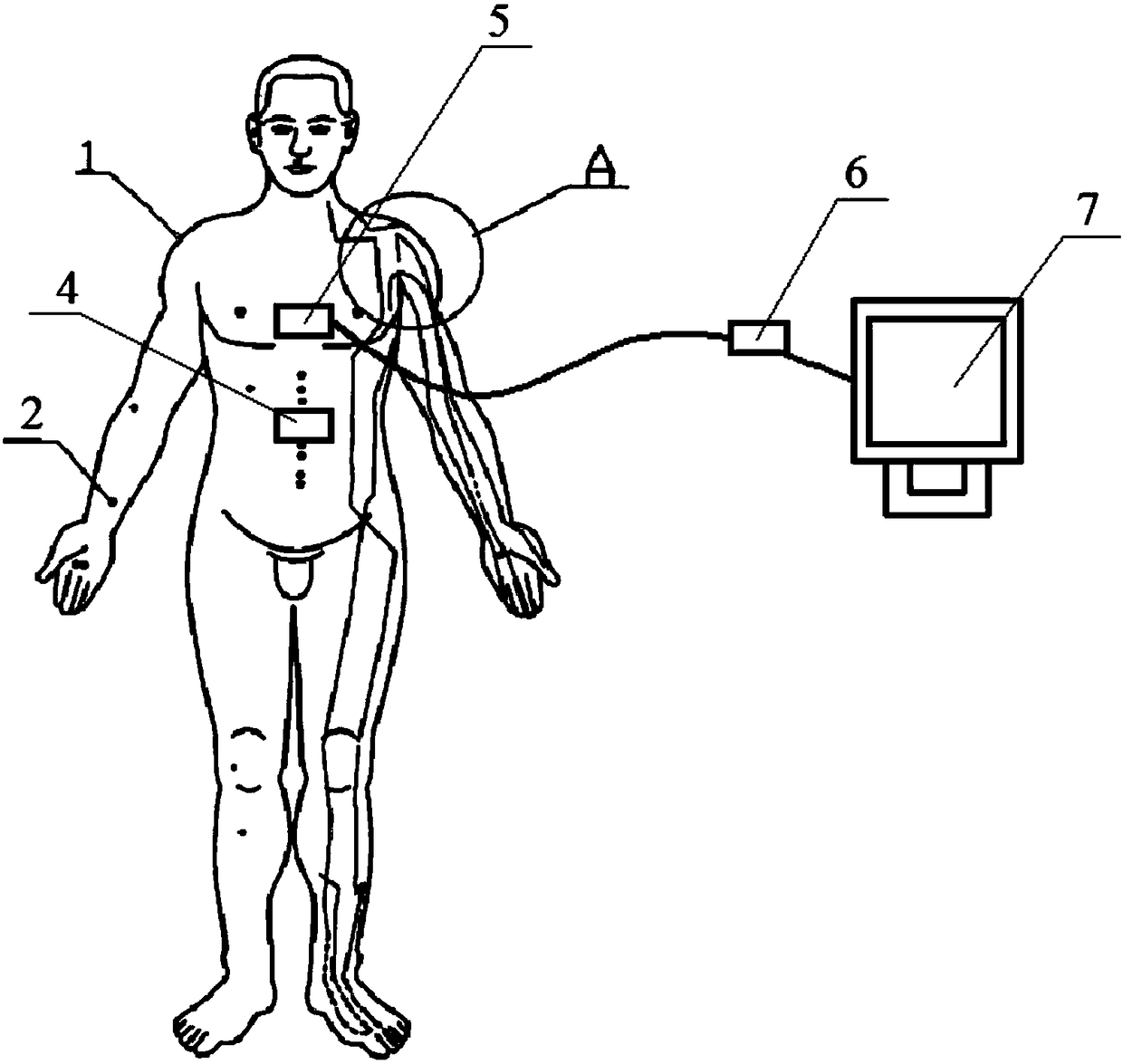

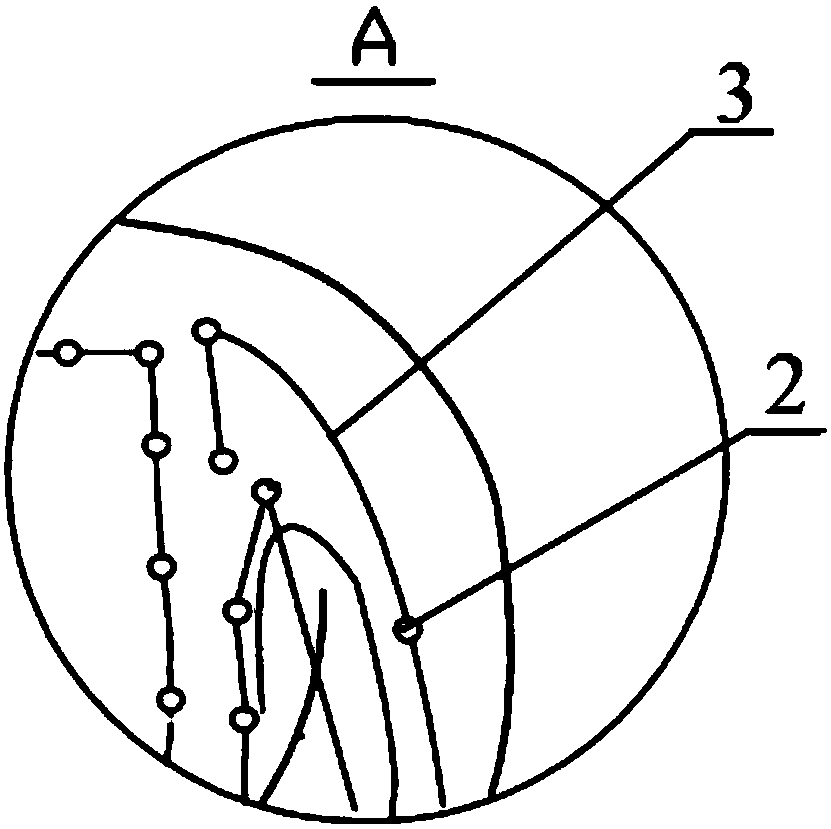

Graphene intelligent simulation human meridian model

PendingCN108109497AEasy to learnIncrease rangeEducational modelsElectrical appliancesAcupressureEngineering

The invention discloses a graphene intelligent simulation human meridian model. The graphene intelligent simulation human meridian model comprises a plurality of graphene pressure sensors, a controller and a terminal, wherein the plurality of graphene pressure sensors are distributed at the acupressure points and the meridians of the human meridian model, the controller is arranged inside the human meridian model, the output ends of the plurality of graphene pressure sensors are connected with the input end of the controller, and the output end of the controller is connected with the terminal.For the graphene intelligent simulation human meridian model provided by the invention, the graphene pressure sensors are arranged at the acupressure points and the meridians of the human meridian model, the numerical values detected by the graphene pressure sensors are transmitted to the terminal, a display screen of the terminal displays the names and efficacies of the corresponding acupressurepoints and meridians, and the pressing force, so that a beginner does not need to read the efficacies of the acupressure points and the meridians by looking at the textbook during learning, the operation of learning is facilitated, and the learning efficiency is high.

Owner:重庆智惠中医药研究院(普通合伙)

Method for bonding mask strips, bonding device, and mask plate

ActiveCN107201498BDoes not affect the fixing accuracyShorten the timeVacuum evaporation coatingSputtering coatingEngineeringProcess time

Owner:BOE TECH GRP CO LTD +1

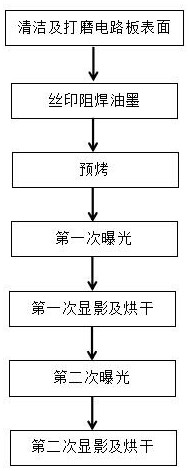

Method for eliminating solder mask ink in via hole of printed circuit board

ActiveCN112492764AReduce manufacturing difficultyReduce manufacturing costInsulating layers/substrates workingCleaning using gasesSolder maskElectrically conductive

The invention discloses a method for eliminating solder mask ink in a via hole of a printed circuit board, which comprises the steps of S1, cleaning a substrate and a conductive copper layer on the surface of the substrate, roughening the surface of the conductive copper layer through a polishing device, and cleaning the substrate and the conductive copper layer again; S2, carrying out silk-screenprinting, specifically, printing an ink layer with a preset color on the conductive copper layer; S3, conducting pre-baking, specifically, pre-baking the silk-screen printed circuit board; S4, performing primary exposure, specifically, performing alignment exposure by using a film, performing photocuring on the solder mask ink, and shielding the via hole and the periphery by using a shading partof the film; S5, developing for the first time, and removing the ink at the position shielded by the shading part of the film; S6, drying the circuit board. S7, performing secondary exposure, specifically, performing secondary alignment exposure by using a film, and performing secondary photocuring on the ink layer; S8, developing for the second time, and removing the residual solder resist ink inthe via hole; and S9, drying the circuit board. The solder mask ink in the via hole can be effectively eliminated, the integrity of an ink layer is ensured, and assembly welding bridge partition is prevented.

Owner:四川英创力电子科技股份有限公司

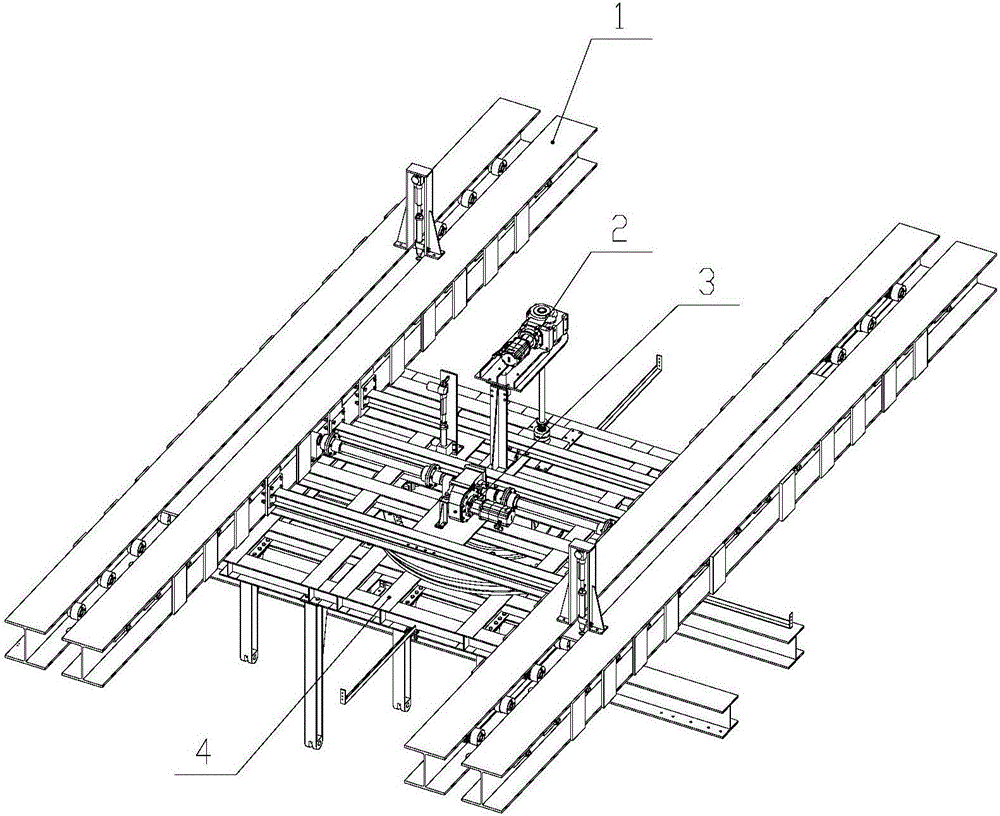

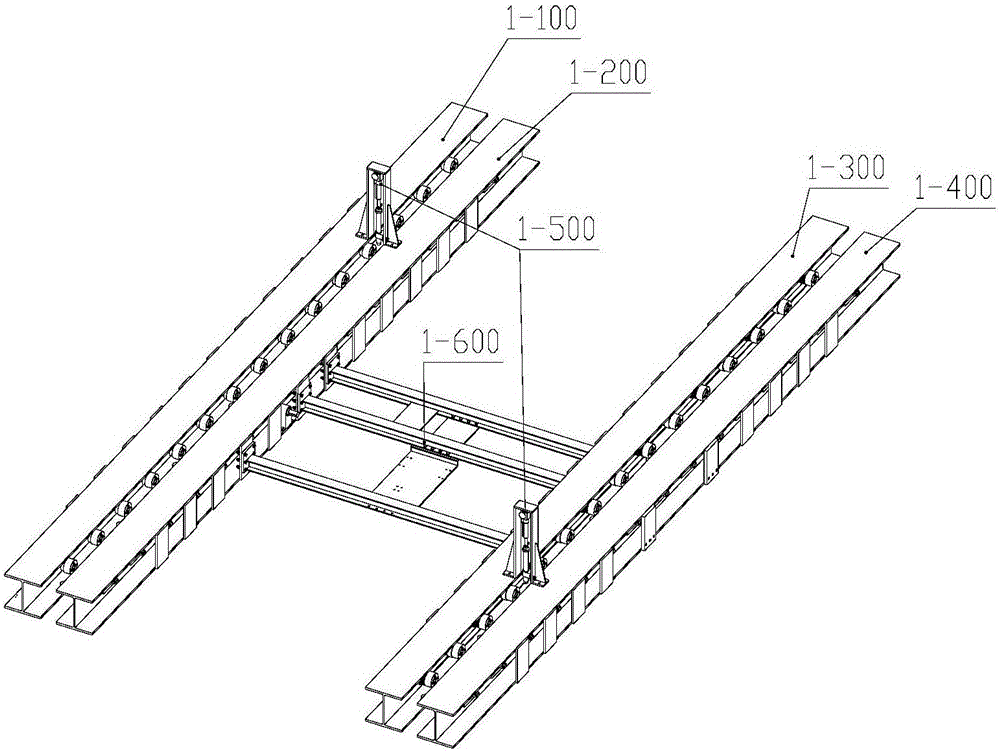

Intelligent passive track trolley system with rotating function

InactiveCN106564812AWith rotation functionRealize the function of automatically rotating the workpieceTravelling gearRunwaysEngineeringBase function

The invention discloses an intelligent passive track trolley system with rotating function, and belongs to the technical field of crane. The intelligent passive track trolley system at least comprises a passive track trolley device, a guide rail device used for loading and guiding the movement of the passive track trolley device, a guide rail driving device used for driving the passive track trolley device to move along the guide rail device, and a rotating driving device used for driving the passive track trolley device to perform rotating movement; wherein the guide rail device comprises a first guide rail group and a second guide rail group which are arranged in parallel and in a mirror image manner; the guide rail driving device is arranged between the first guide rail group and the second guide rail group; and the rotating driving device is arranged on the guide rail driving device. According to the above design, the intelligent passive track trolley system with rotating function is provided with the basic functions of conventional track trolleys, and the functions of track trolley autorotation workpieces at the same time.

Owner:TIANJIN HOISTING EQUIP

A low-precision inertial navigation initial alignment method based on quaternion ckf

InactiveCN103900608BReduced alignment accuracyEasy alignmentMeasurement devicesEarth's rotationGyroscope

The invention provides a low-precision inertial navigation initial alignment method based on a quaternion CKF. The low-precision inertial navigation initial alignment method comprises the following steps: carrying out coarse alignment by utilizing measured values of an accelerometer and a magnetometer to obtain a coarse attitude matrix; taking a position and a speed error as value measurement by using accurate outside information provided by a GPS (Global Position System); carrying out nonlinear filtering by the quaternion CKF to obtain an attitude error matrix; and finally, correcting by using the attitude error matrix to obtain an accurate attitude matrix. According to the low-precision inertial navigation initial alignment method, the value measurement of the gravitational acceleration and the magnetic force, which is carried out by the accelerometer and the magnetometer, is subjected to the coarse alignment. The problems that the gyroscope performance is low under the condition of a low-precision inertial device, the rotation angle speed of the earth can not be accurately sensed and a traditional coarse alignment method can not be applied are solved; furthermore, the quaternion CKF provided by the method can be used for a non-linear model of a large angle error, can still finish alignment under the condition of a large orientation misalignment angle and has high alignment precision.

Owner:HARBIN ENG UNIV

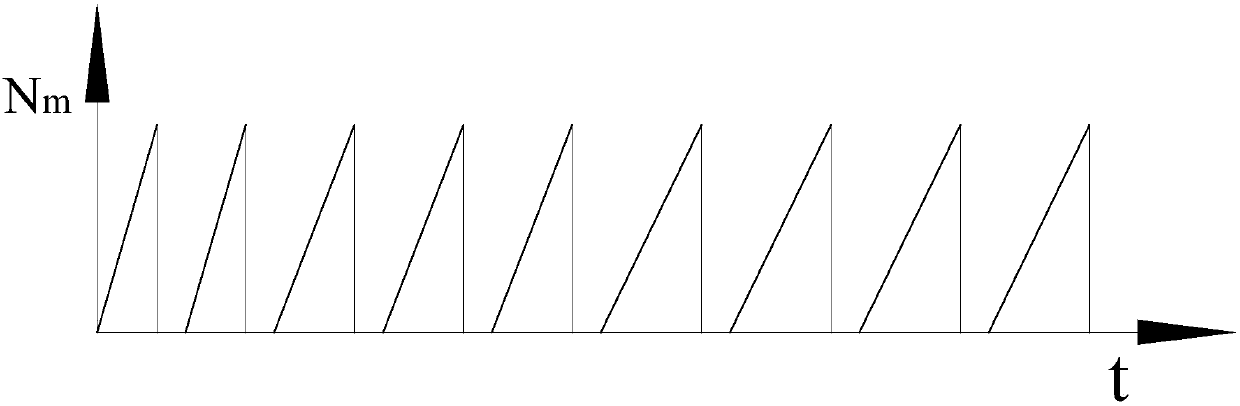

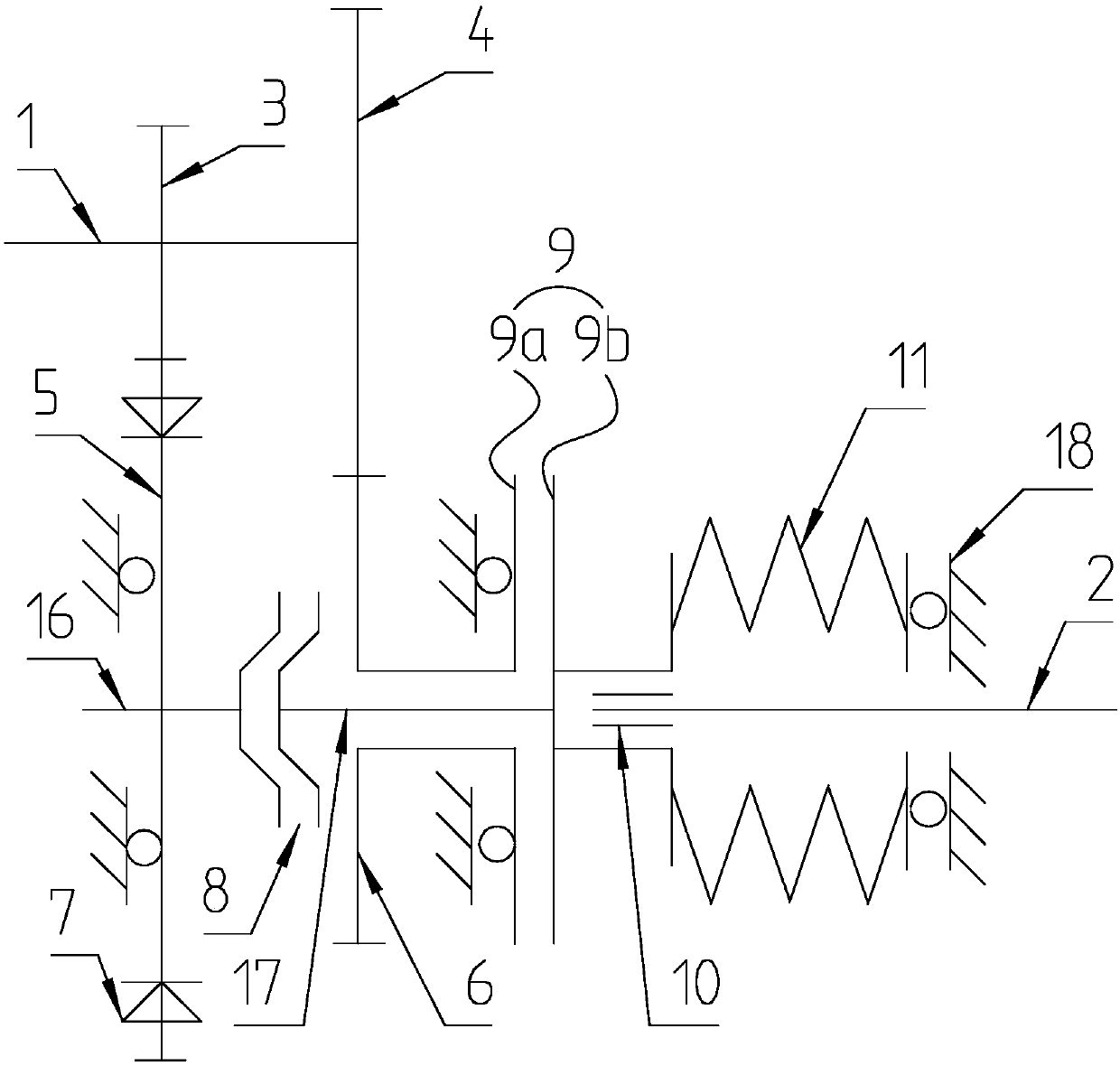

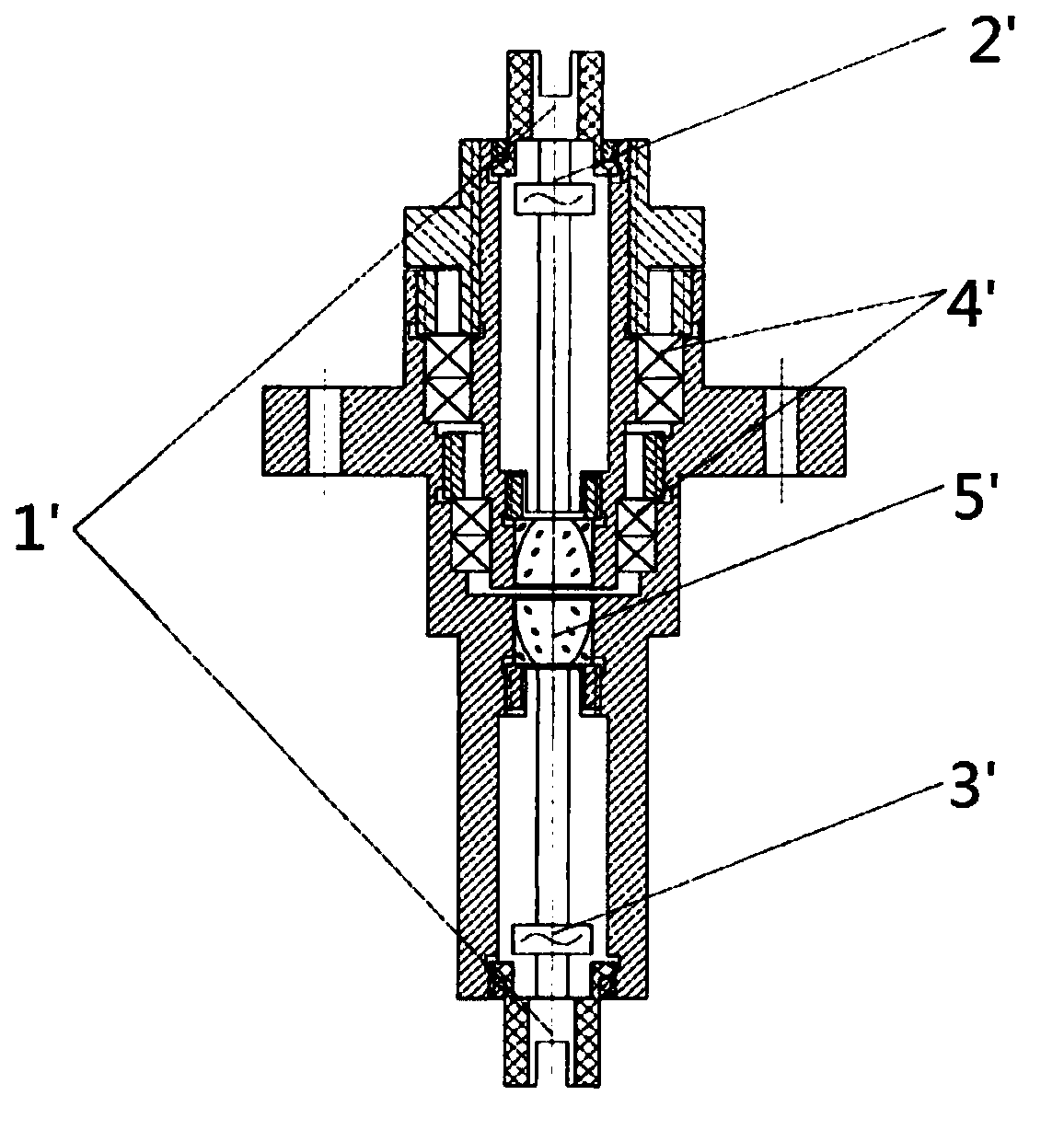

Method for testing service life of friction clutch of torque backlash type gearshift mechanism

ActiveCN107860577AReduced alignment accuracyLower requirementMachine gearing/transmission testingLower limitTest efficiency

The invention discloses a method for testing service life of a friction clutch of a torque backlash type gearshift mechanism. The method comprises the following steps of S1, detaching one or a plurality of members in a low-speed-gear driving tooth, low-speed-gear driven tooth and an overrunning clutch; S2, connecting an input shaft with a driving motor, and locking an output shaft; S3, setting a rotating speed parameter and a highest cycling number-of-times Nmax of the driving motor; S4, setting testing end conditions of a, time ratio of a period in which Tm is smaller than or equal with Tdn_min / i2 in a rotating speed increase period of the driving motor exceeds deltax, wherein Tm is the torque of the driving motor, Tdn_min is a gear shifting-down torque allowable range lower limit value,i2 is a high-speed-gear transmission ratio of the torque backlash type gearshift mechanism, and deltax is a preset value; b, the cycling number-of-times Nx of the driving motor satisfies a condition of Nx=Nmax; and S5, starting the driving motor, and ending testing when a random condition the step S4 is satisfied. The method according to the invention has advantages of simplifying a testing deviceand a testing flow, reducing testing cost, and improving testing efficiency and testing precision.

Owner:SOUTHWEST UNIVERSITY

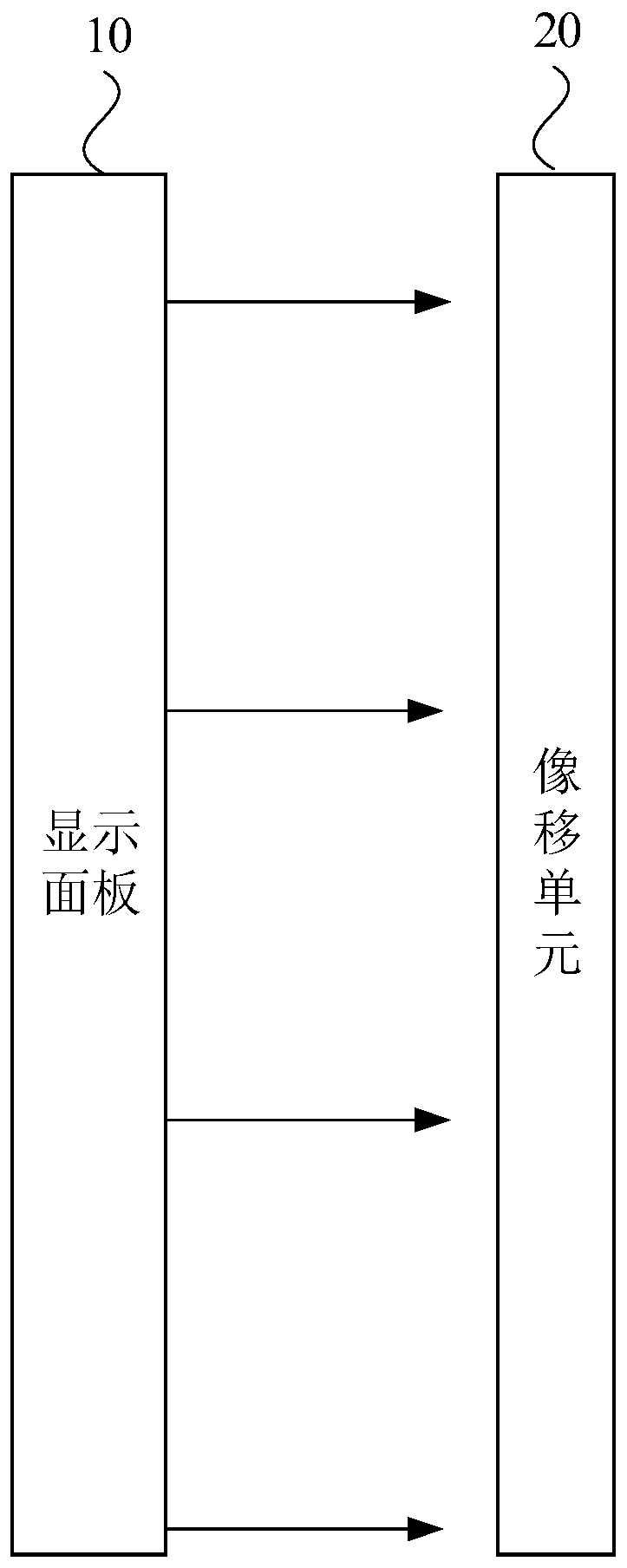

Display device

ActiveCN109814305AHigh-resolutionClosely arrangedSolid-state devicesNon-linear opticsImage resolutionDisplay device

The embodiment of the invention discloses a display device. The display device comprises a display panel and an image motion unit located at the light emergence side of the display panel; the displaypanel comprises a pixel unit array formed by multiple pixel units, and each pixel unit comprises various sub pixels for giving out light different in color; in the row direction, the light giving colors of the adjacent sub pixels are different; in the line direction, the light giving colors of the adjacent sub pixels are identical; the image motion unit does not move the emergence path of the emergent light ray of a first pixel unit row and is used for moving the emergence path of the emergent light ray of the sub pixels in a second pixel unit row in the row direction by a preset distance, sothat the adjacent sub pixels with three or more different colors form the first pixel unit, one or more of sub pixels and other pixels in the first pixel units are located on different rows, and the sub pixels can give out white light; the first pixel unit row and the second pixel unit row are alternatively arrayed in the line direction. According to the technical scheme, the resolution ratio of the display device can be effectively improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

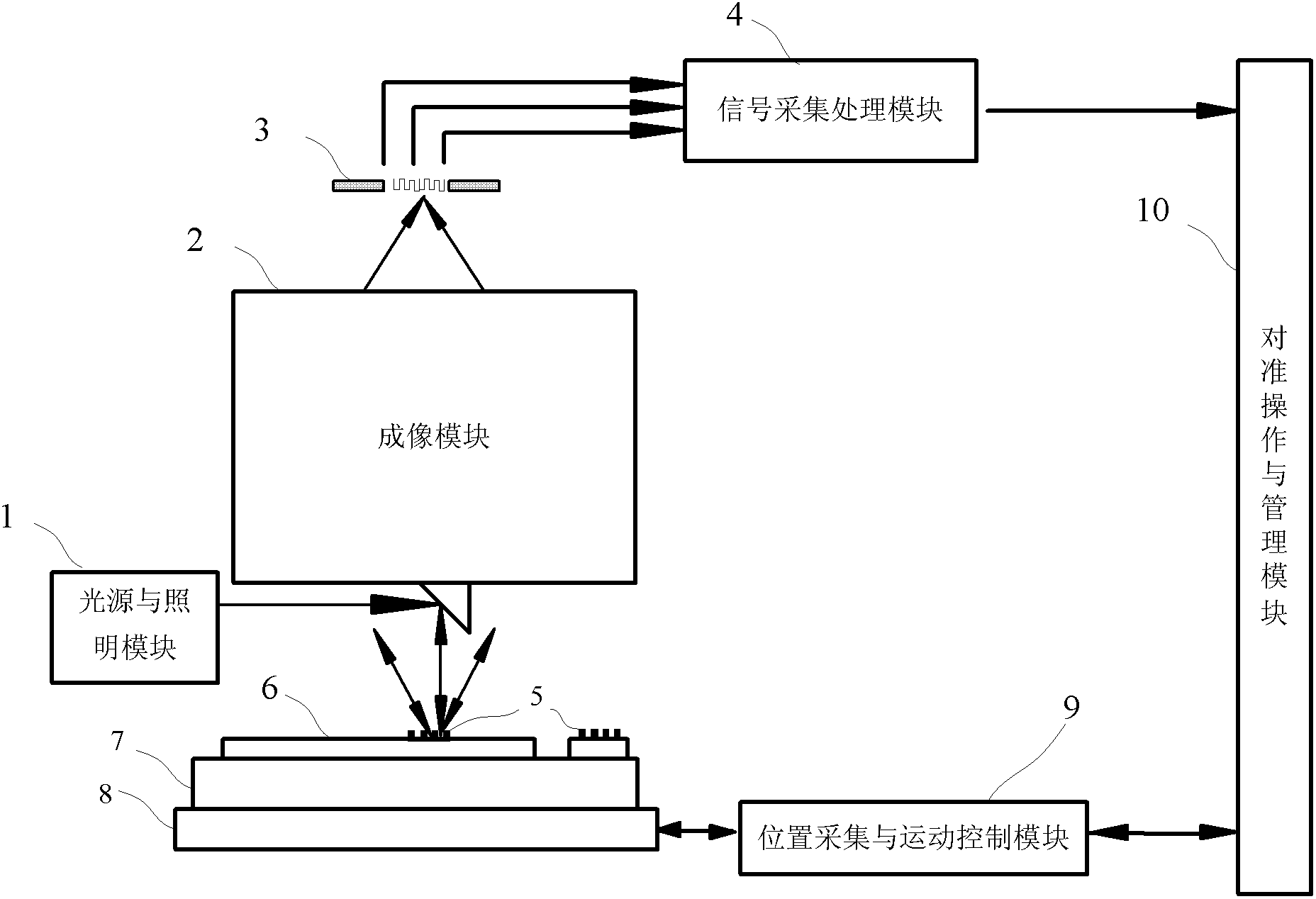

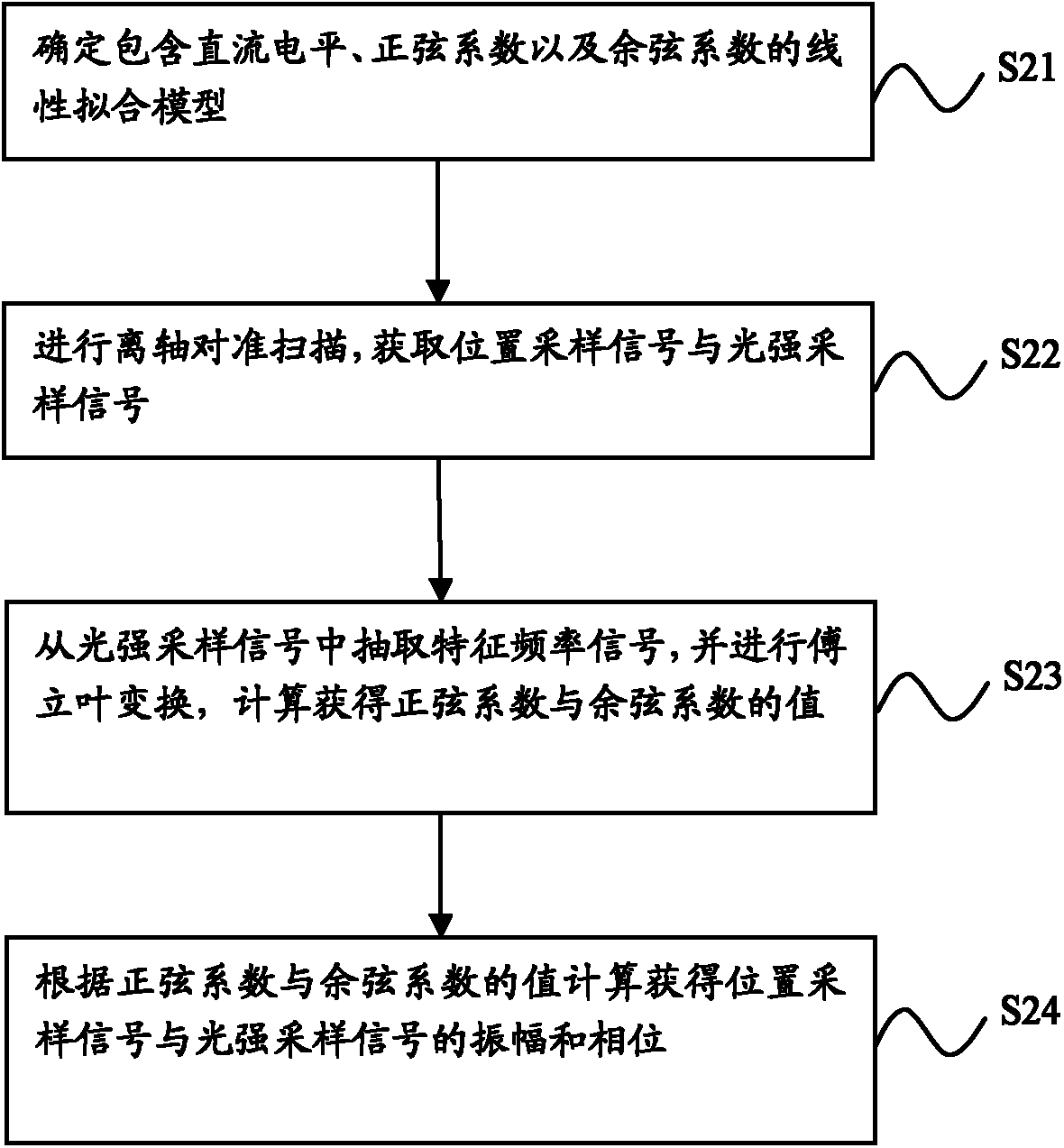

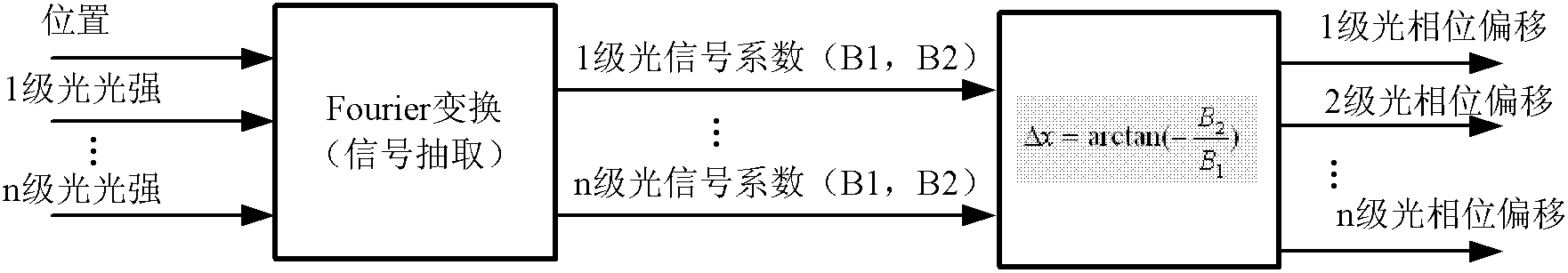

Off-axis signal processing method

ActiveCN102866602AReduced alignment accuracyReduce computing timePhotomechanical exposure apparatusMicrolithography exposure apparatusFast Fourier transformFourier transform on finite groups

The invention discloses an off-axis signal processing method, comprising the following steps: (a) determining a linear fitting model containing direct-current level, sine coefficient and cosine coefficient; (b) conducting off-axis aligning scanning to acquire position sampling signals and light intensity sampling signals; (c) extracting characteristic frequency signals from the light intensity sampling signals and conducting Fourier transform, and calculating values of the sine coefficient and cosine coefficient; and (d) calculating the position sampling signals and light intensity sampling signals according to the values of the sine coefficient and cosine coefficient. According to the invention, the aligning accuracy can not be reduced, and simultaneously the calculation time is greatly reduced, thus the yield is raised.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Exposure method for color film substrate

PendingCN111694188AReduced precision requirementsHigh precisionPhotomechanical apparatusOriginals for photomechanical treatmentColor filmLight beam

The invention discloses an exposure method for a color film substrate. The method comprises the following steps of S1, providing a substrate, forming black matrix layers at intervals on an upper surface of the substrate, and taking a region without the black matrix layers as an opening region; S2, covering an upper surface of the opening region of the substrate and an upper surface of the black matrix layer with a negative photosensitive adhesive layer; S3, providing a mask version body of which the upper surface is provided with a shielding layer, forming the mask version body below the substrate, and arranging the shielding layer towards the substrate; and S4, exposing light beams perpendicular to a plane of a mask plate penetrating through the region, not provided with the shielding layer, of the mask plate body from the lower portion of the mask plate body, and the photosensitive adhesive layer so that the color filter layer is formed through the process including development. Themethod is advantaged in that the mask plate is formed on a lower surface of the substrate, the shading property of a black matrix layer on an upper surface of the substrate is utilized, so segment difference is eliminated, and the precision requirement of the mask plate and the alignment precision requirement of an exposure machine are reduced.

Owner:信利(仁寿)高端显示科技有限公司

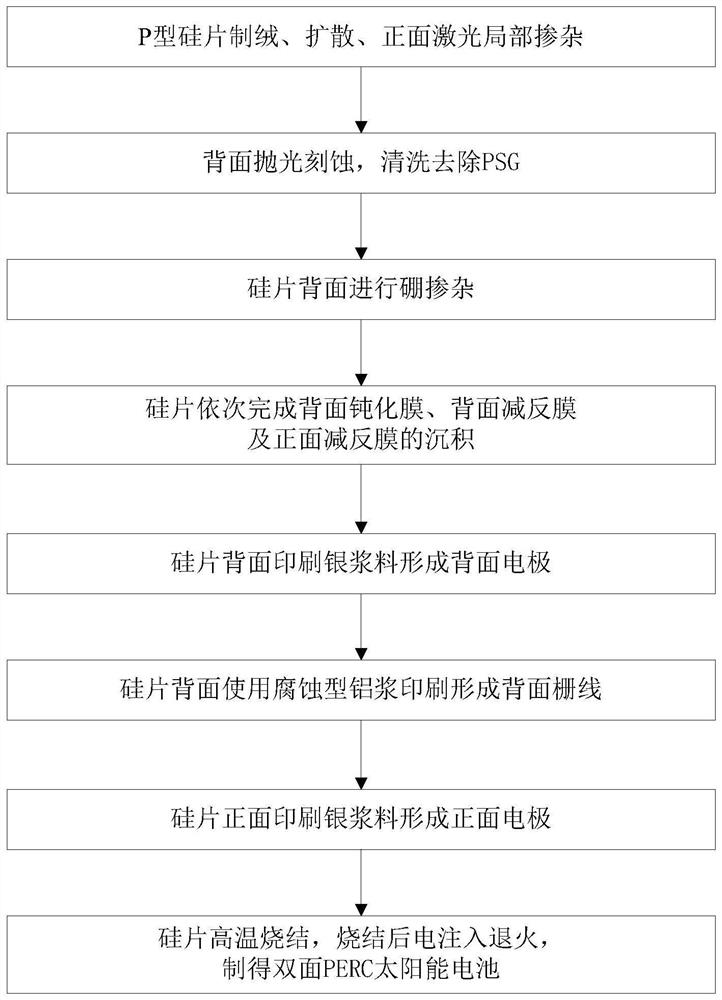

Double-sided PERC solar cell and preparation method thereof

InactiveCN112133789AAvoid mechanical propertiesAvoid fragmentationFinal product manufacturePhotovoltaic energy generationMetallic aluminumElectrical battery

The invention discloses a double-sided PERC solar cell and a preparation method thereof. The preparation method comprises the following steps of: performing texturing, diffusion, front laser doping, back polishing and etching, back passivation film deposition, back anti-reflection film deposition and front anti-reflection film deposition on a P-type silicon wafer; and printing a back electrode andback grid lines on the back anti-reflection film, printing a front electrode on the front anti-reflection film, and performing sintering and electric injection annealing. The back grid lines are printed by adopting corrosion type aluminum paste, and the corrosion type aluminum paste etches the back anti-reflection film and the back passivation film in the sintering process to form ohmic contact with the silicon wafer. According to the method, the corrosion type aluminum paste is printed on the back surface of the cell, the back anti-reflection film and the passivation film are etched and penetrated during sintering to realize local opening, an existing laser opening process is replaced, good ohmic contact between metal aluminum and a silicon wafer is realized in combination with back surface boron doping, and mechanical damage and fragment rate caused by laser opening are avoided; and the production process is simplified, and the production cost is reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

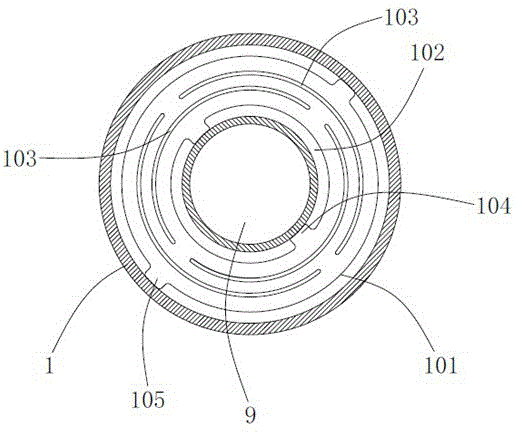

Wireless smooth ring for rotating mechanism

PendingCN111147143AOvercoming Fatigue and Longevity IssuesHigh communication rateCondensersElectromagnetic transceiversContact laserHigh transmission

The invention relates to a wireless smooth ring for a rotating mechanism. The wireless smooth ring comprises a mechanical shell with a cylindrical cavity, a signal transmitting mechanism, a signal receiving mechanism, a circuit board and an external connector, wherein the signal transmitting mechanism and the signal receiving mechanism are fixed in the mechanical shell; the signal transmitting mechanism and the signal receiving mechanism are connected with the circuit board through optical fibers; the circuit board comprises a signal transmitting circuit and a signal receiving circuit; the external connector is used for supplying power to the slip ring and transmitting and receiving data; a wireless non-contact laser communication mode is adopted for signal transmitting and receiving. Thebeneficial effects of the invention are that the wireless smooth ring is longer in service life and higher in transmission rate; higher transmission speed and lower processing precision requirements are realized; and the lower assembly requirement and the lower machining requirement are achieved.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

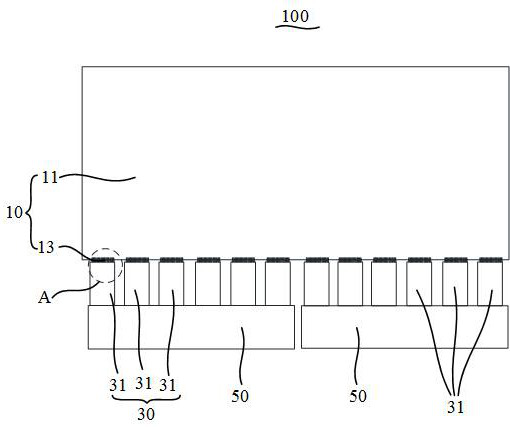

Display panel, manufacturing method thereof, and display device

ActiveCN113514975BEasy to controlNot prone to voltage biasStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The present application discloses a display panel, a manufacturing method thereof, and a display device. The display panel includes an array substrate and a driver. The array substrate includes a display part and a binding part. The binding part includes a plurality of binding electrodes arranged at intervals. The component includes a driving part, the driving part is provided with a plurality of driving electrodes arranged at intervals, and the plurality of binding electrodes include a first high-voltage electrode group and a second high-voltage electrode group adjacently arranged, and the first high-voltage electrode group includes at least Two first high-voltage electrodes, the second high-voltage electrode group includes at least two second high-voltage electrodes spaced apart, one of the two adjacent driving electrodes is crimped and fixed with the corresponding at least two first high-voltage electrodes, and the other It is crimped and fixed to at least two corresponding second high-voltage electrodes, and the distance between the two driving electrodes is greater than the distance between the first high-voltage electrode group and the second high-voltage electrode group. The display panel of the technical solution of the present application can improve the problem of short-circuit burn caused by voltage bias.

Owner:HKC CORP LTD

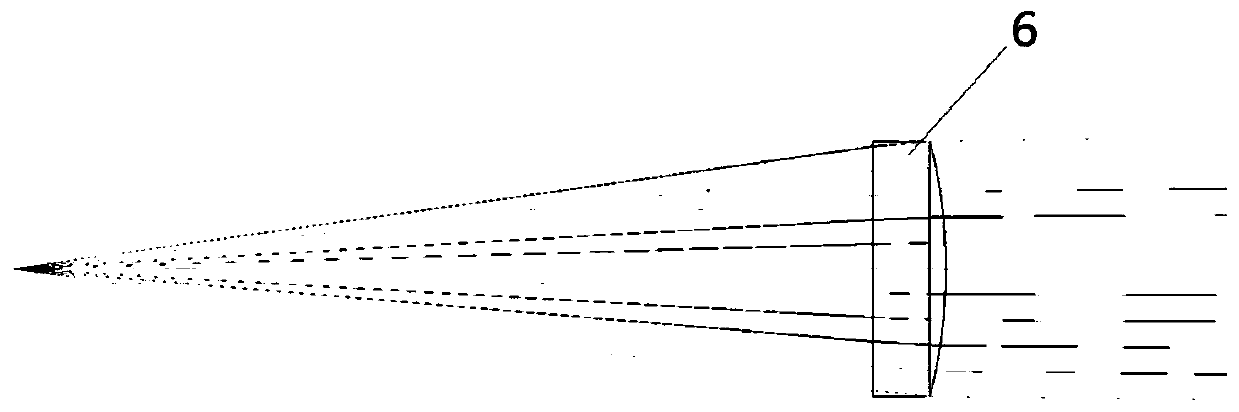

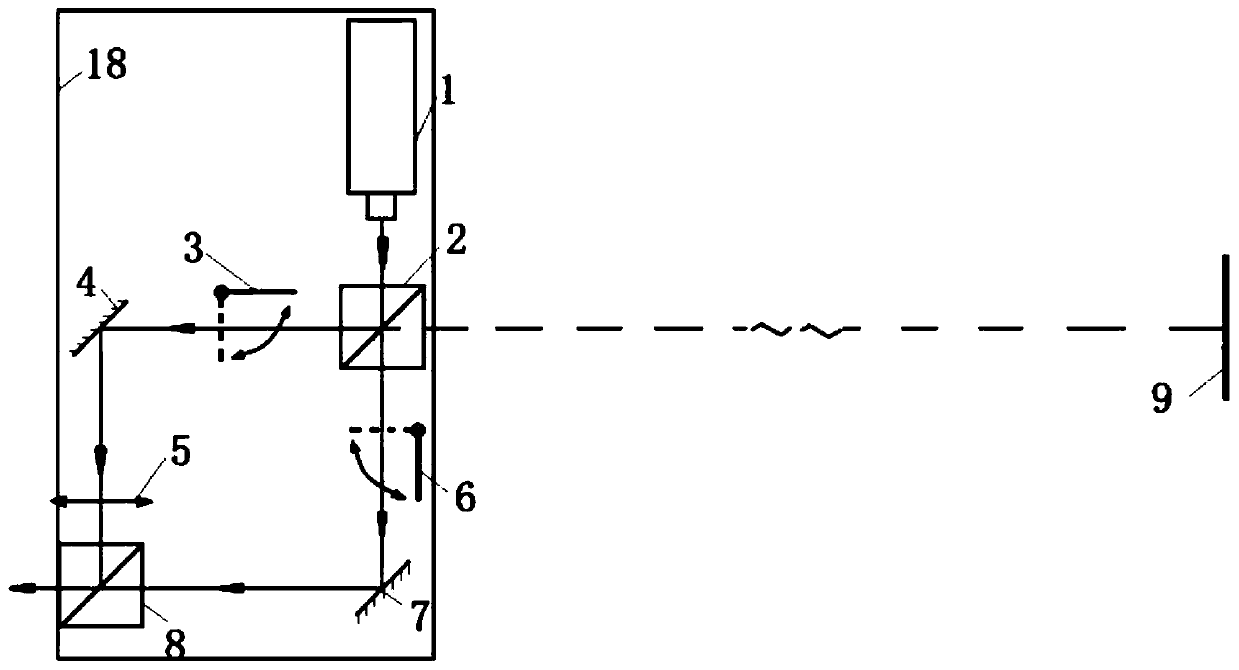

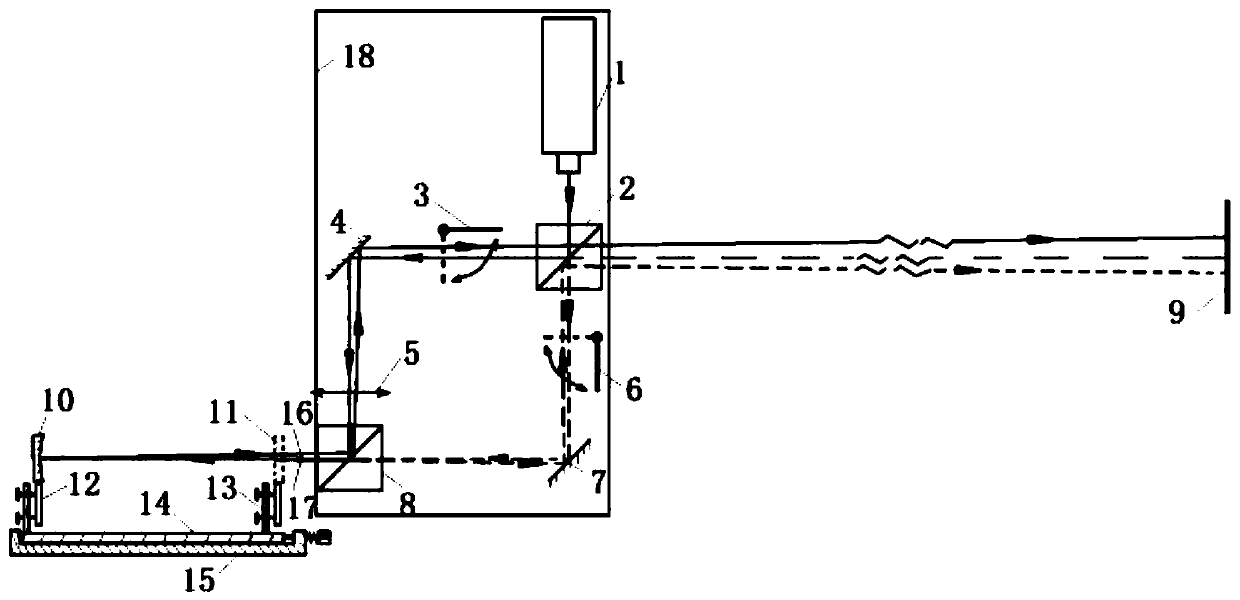

Plano-concave laser cavity double-optical-path alignment device and method based on Gaussian beam

ActiveCN110459946AImprove alignment accuracyReduce alignment spotsOptical resonator shape and constructionOptical elementsResonant cavitySolid-state laser device

The invention discloses a plano-concave laser cavity double-optical-path alignment device and method based on a Gaussian beam, belonging to the field of solid-state laser device laser cavity adjustment. Two optical paths are set to align concave and plane cavity lenses with different refractive characteristics, and a positive focal power lens group with a focal point that coincides with a spherical center of the concave cavity lens is set in a concave cavity lens alignment optical path. For the Gaussian beam, a composite system formed by the lens group and the concave cavity lens is equivalentto a flat plate, so the refractive characteristics of the concave cavity lens are modified, an alignment spot with a similar size with the plane cavity lens is obtained, and the alignment accuracy ofa resonant cavity is improved. For resonant cavities with different concave cavity lens radii, the alignment can be achieved only with the satisfaction of the coincidence of a positive focal power lens group focal point and the spherical center of the concave cavity lens, and the alignment accuracy is stable without degradation.

Owner:NANCHANG HANGKONG UNIVERSITY

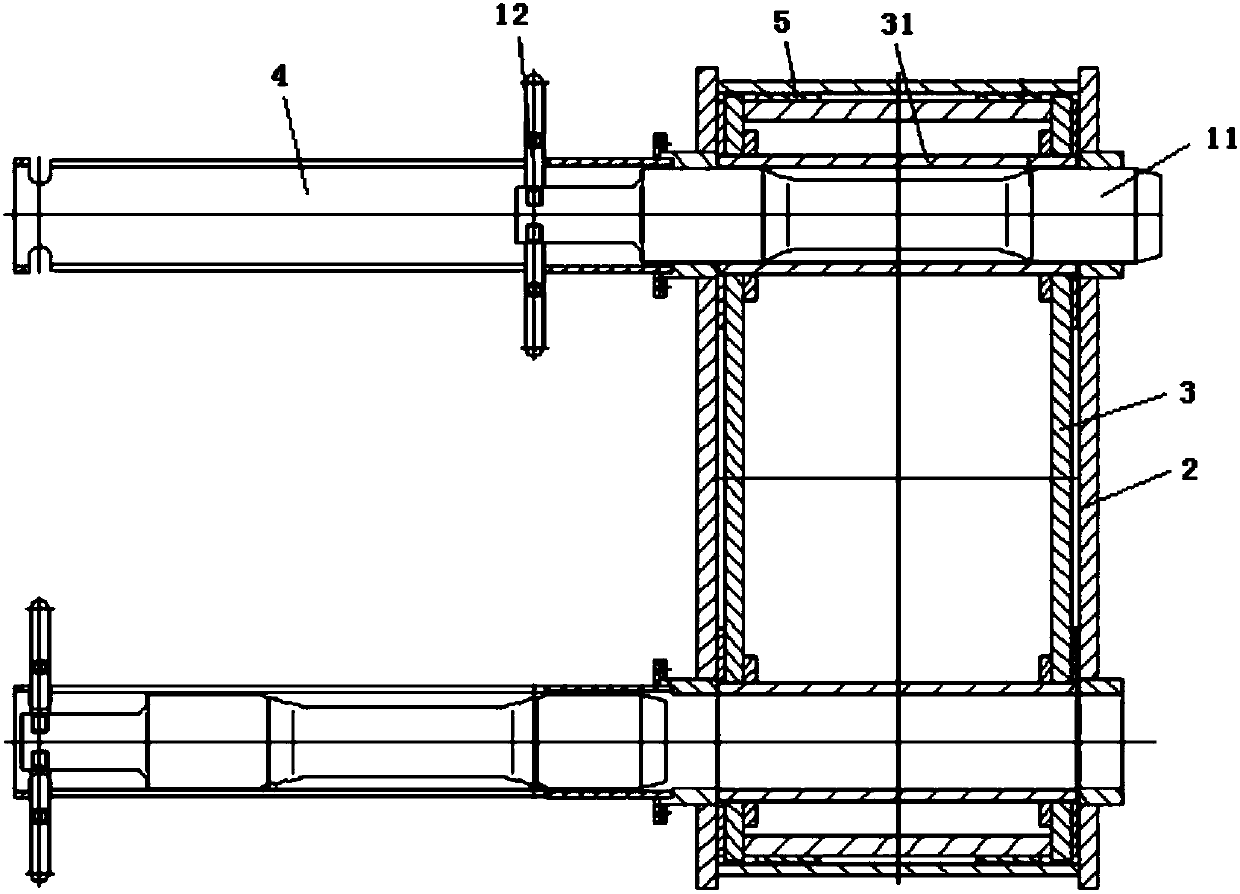

Top-loading coke oven smokeless coal charging device

ActiveCN103773396BReduced air volume requirementsReduced alignment accuracyCharging devicesDistillation gas withdrawalCoke ovenMechanical engineering

The invention discloses a smokeless coaling device of a top-charging coke oven. The smokeless coaling device comprises a flashboard device, and a coal charging sleeve, wherein the flashboard device is arranged at the upper part of the coal charging sleeve. The smokeless coaling device is characterized in that a built-in flashboard device is arranged inside the flashboard device; the coal charging sleeve comprises an upper sleeve, a fixed sleeve, a movable sleeve, a sleeve sealing device, and a fire hole sealing device; a fire hole sealing base matched with the fire hole sealing device is arranged on the plane of the fire hole; an outer sleeve capable of axially stretching is also arranged; the outer sleeve is sleeved outside the fire hole sealing device; the upper end of the outer sleeve is connected with the movable sleeve; a work surface butted with the plane of the fire hole is formed at the lower end of the outer sleeve; a drive device guide rack is arranged at the side of the coal charging sleeve; and a movable sleeve drive device for driving the movable sleeve to axially move up and down and an outer sleeve drive device for driving the outer sleeve to axially stretch are connected with the drive device guide rack. By adopting the device, effective sealing of the fire hole of the coal charging furnace is achieved, a raw coke oven gas generated in the coal charging process enters a gas collecting pipe system through an ascend pipe, and the air quantity requirements on a dust removal system also can be reduced.

Owner:苏循高 +1

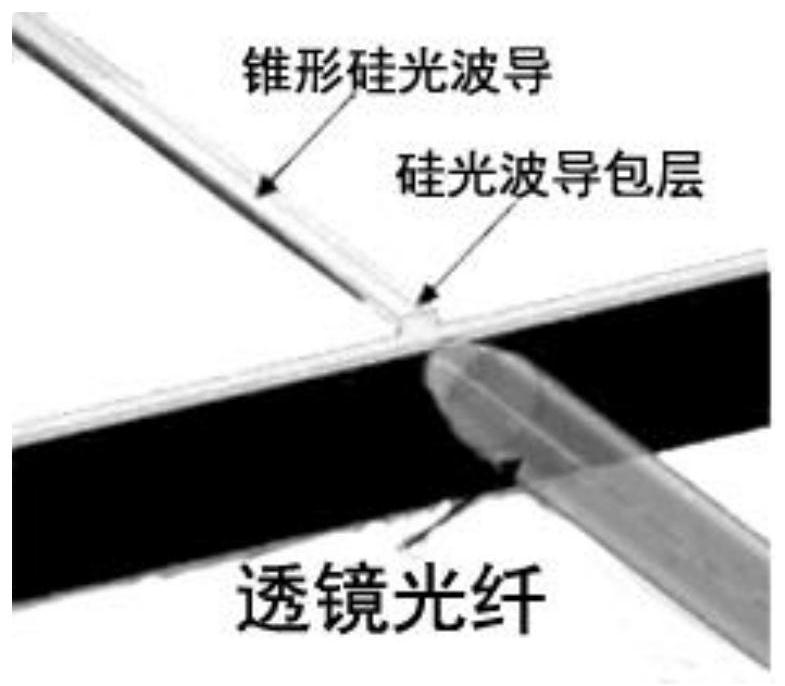

Optical fiber and optical waveguide coupling method and structure and wafer testing method

InactiveCN113568102AImprove coupling efficiencyReduced alignment accuracySemiconductor/solid-state device testing/measurementCoupling light guidesMaterials scienceWafer testing

The invention discloses an optical fiber and optical waveguide coupling method and structure and a wafer testing method. The coupling method comprises the following steps: manufacturing a required waveguide in a block of a wafer; etching a groove in one end of the waveguide, wherein the groove is used for inserting an optical fiber in the direction in which the waveguide forms a first preset angle; cutting the end surface of the optical fiber to be inserted into the groove into a second preset angle, and coating a layer of anti-reflection film on the cut surface; and inserting the cut optical fiber into the groove, wherein light passing through the optical fiber enters the waveguide after being emitted by the anti-reflection film. According to the invention, the problem of the coupling mode between the single-mode optical fiber and the silicon optical waveguide in the optical chip test in the prior art is solved, so that the coupling efficiency of the optical fiber and the silicon optical waveguide is improved, and the alignment precision and tolerance are reduced.

Owner:CENT SOUTH UNIV

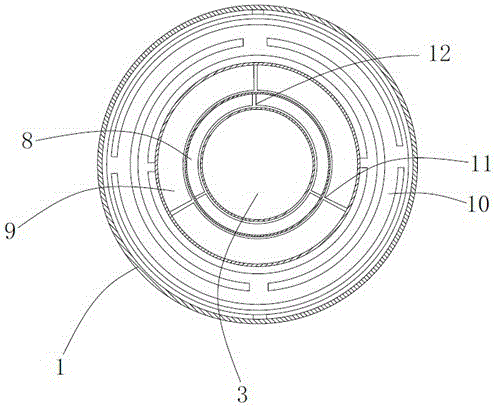

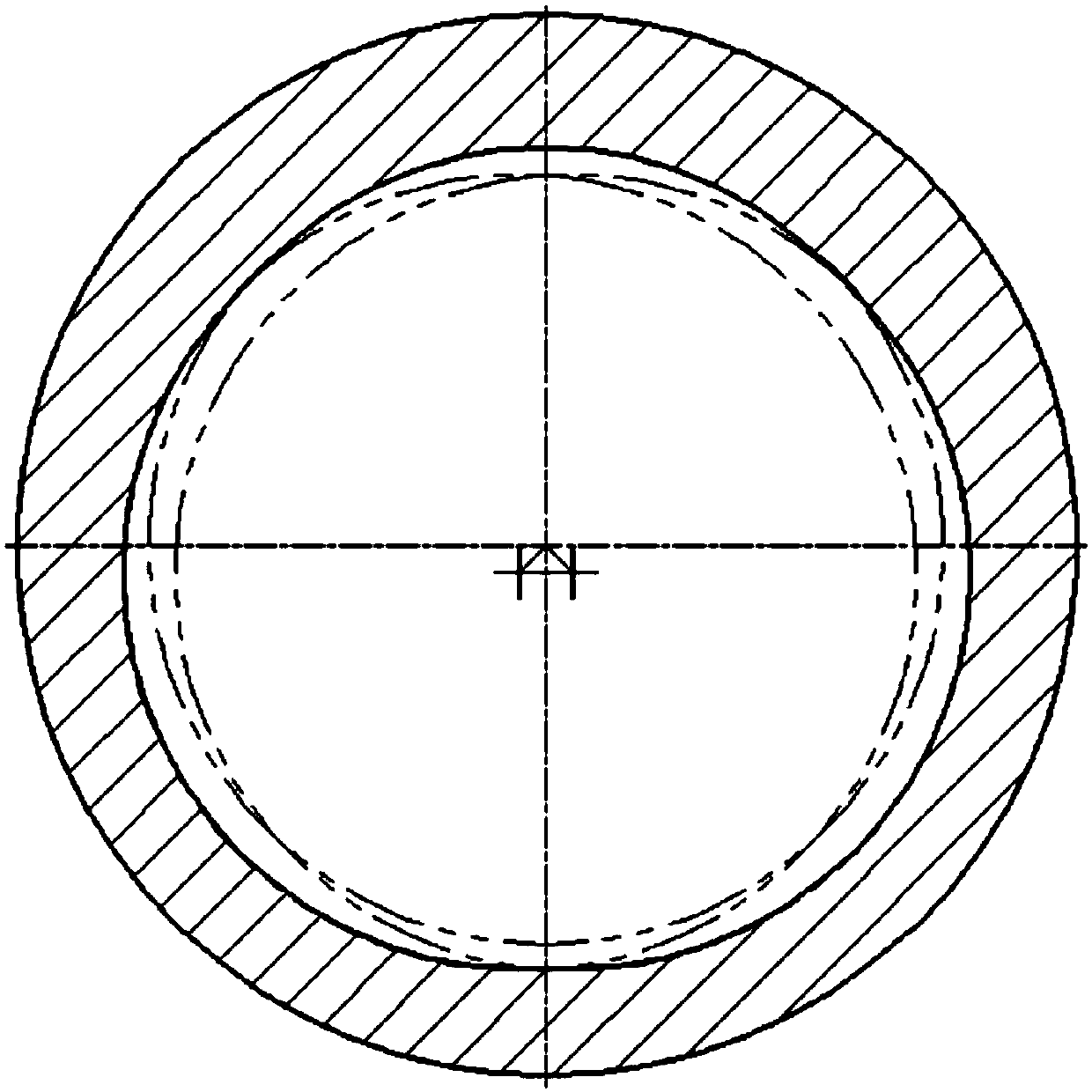

A high stability carbon dioxide laser cooled by reflux

ActiveCN103682976BSmall amount of deformationGuaranteed stabilityLaser detailsWater coolingStorage tube

A highly stable carbon dioxide laser that is cooled by recirculation. The carbon dioxide laser comprises a gas storage tube (1), a water cooling tube (2) and a discharge tube (3) sequentially sleeved one over the other from the outside inward; the two ends of the gas storage tube (1) are respectively provided with a reflective lens (4) and an output lens (5); the gas storage tube (1) is provided with a water inlet tube (7) and a water outlet tube (6) connected to the water cooling tube (2); the water cooling tube (2) is a double-layer structure comprising an inner-layer water cooling tube (8) connected to an outer-layer water cooling tube (9); the water inlet tube (7) and the water outlet tube (6) are respectively connected to the inner-layer water cooling tube (8) and the outer-layer water cooling tube (9); the water inlet tube (7) and the water outlet tube (6) are disposed at the same end of the water cooling tube (2). The deformation of the water inlet tube (7) and the water outlet tube (6) has reduced impact on the cylindricity of the gas storage tube (1), thus allowing use of a constant temperature device with low constant temperature precision to reduce costs, or even to eliminate the constant temperature device and further reduce costs.

Owner:CHENGDU WEESON TECH

A telescopic outrigger for large-scale construction equipment that can be easily plugged in and out

InactiveCN106522103BReduce labor intensityEasy to plug and unplugBridge erection/assemblyEngineeringUltimate tensile strength

Owner:宿州学院

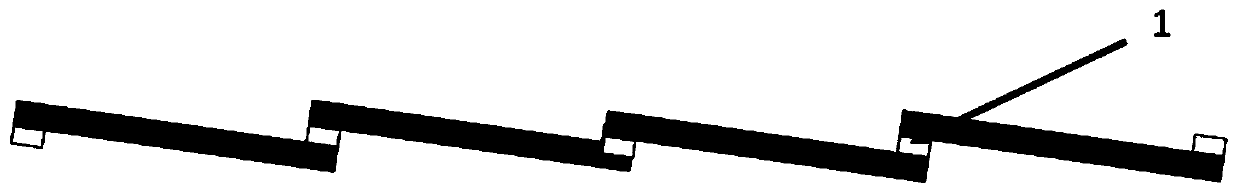

Solar cell string, solar cell module and manufacturing method thereof

ActiveCN109326665BReduce wasteSimple printing processPhotovoltaic energy generationSemiconductor devicesBusbarEngineering

The invention relates to a solar battery string, comprising more than two cells serially connected in stack form, where each cell includes an aluminum back field, a back passivated layer, a polysilicon substrate, a positive passivated layer, an antireflective film, positive silver fingers and a positive silver electrode which are arranged sequentially from bottom to top; in two cells serially connected in stack manner, the positive silver electrode of the front cell is connected with the aluminum back field of the rear cell via conductive glue; in the cells serially connected in stack manner,a busbar is connected with the aluminum back field of the first cell via conductive glue, and a busbar is connected or directly welded to the positive silver electrode of the last cell via conductiveglue. The solar battery string herein has the advantages that the usage of back silver paste can be decreased, the silkscreen printing process is simplified, and the material cost is low; the back silver electrodes are omitted while the conducting capacity is equivalent to that of the string having the back silver electrodes; conductive connection is reliable and stable; the passivated area of thealuminum back field is enlarged, so that photon utilization efficiency is improved; in addition, the requirement on aligning precision of the stack process is lowered; gaps among the modules are utilized, and the cells that can be added under the same area are 13% and above more than those in conventional modules.

Owner:CHANGCHUN YONGGU TECH

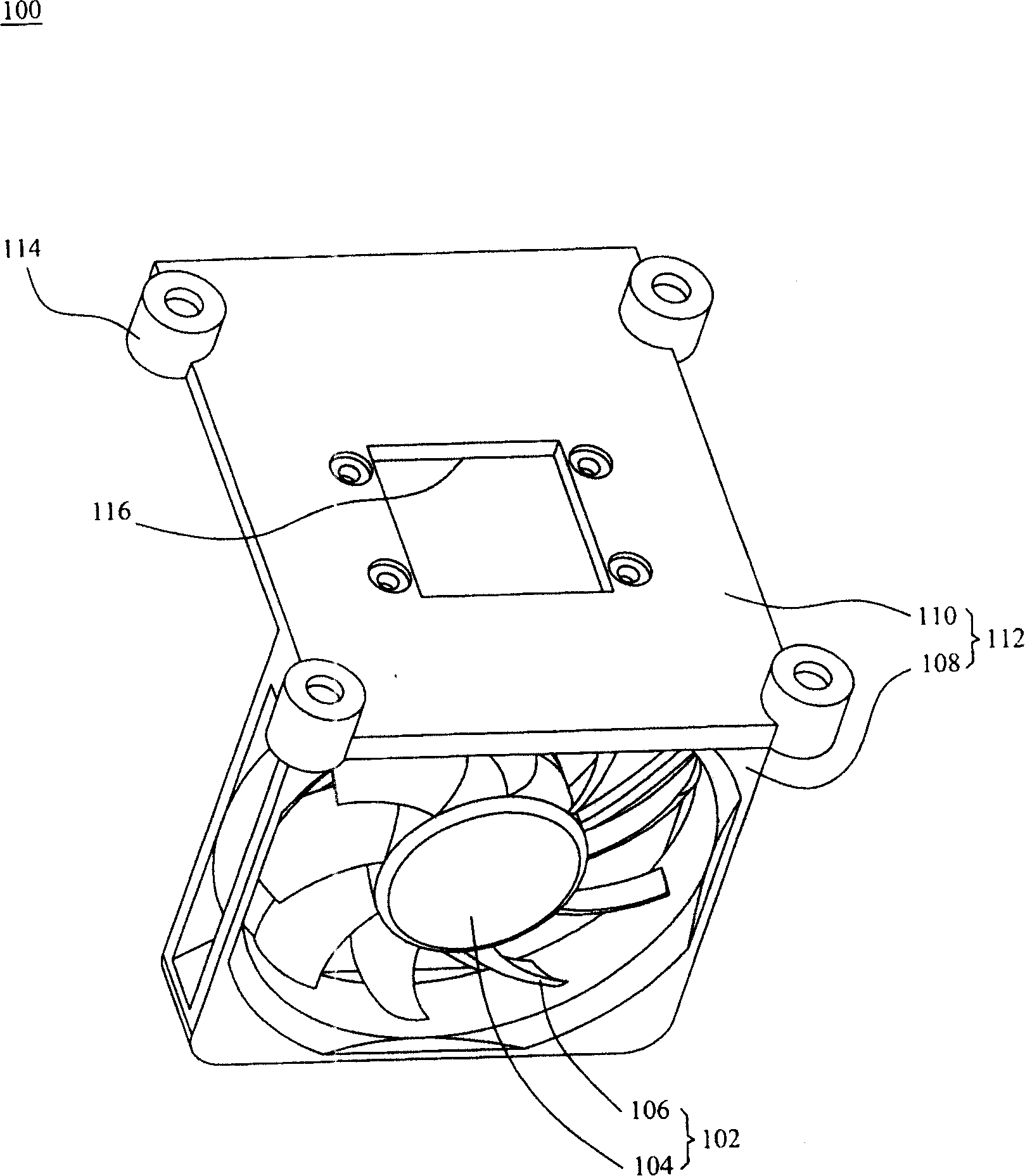

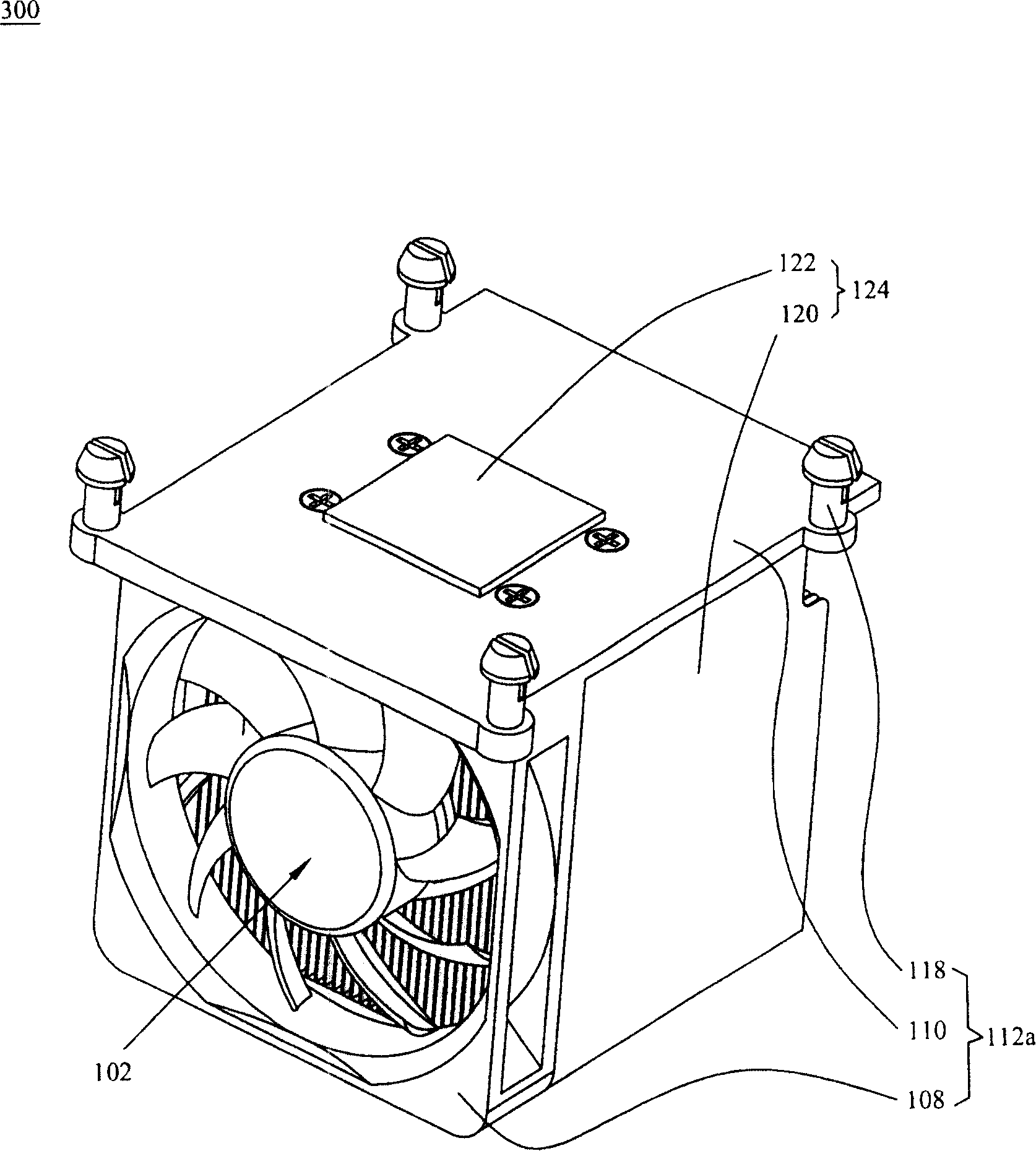

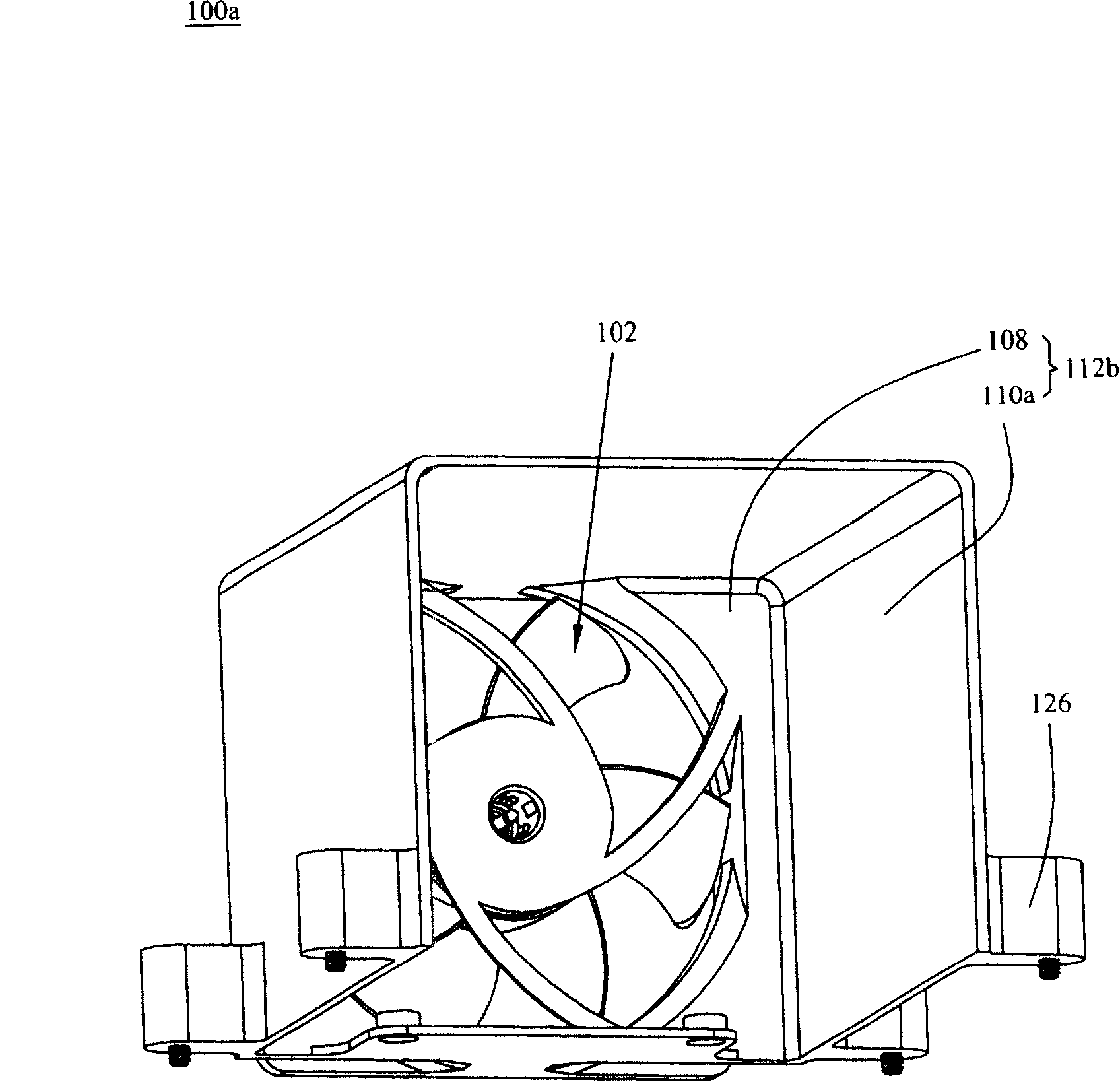

Heat radiating module and fan thereof

InactiveCN101163387AReduce in quantityReduce the number of craftingInstrumental cooling apparatusCooling/ventilation/heating modificationsImpellerComputer module

The invention discloses a heat dissipating module, including a fan and at least one radiator. The fan is provided with a fan frame and an impeller. The fan frame is provided with a body and at least one extending part, wherein the extending part is protrudent from at lease one side of the body. The extending part is used for being connected with a circuit board. The impeller is contained inside the body. The radiator is connected with the extending part and is used for leading out the heat produced by at least one electronic element of the circuit board.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com