Method for eliminating solder mask ink in via hole of printed circuit board

A technology for printed circuit boards and solder mask inks, which is applied in the directions of printed circuits, printed circuit manufacturing, and printed circuit secondary processing. Difficulty, improve cleaning effect, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

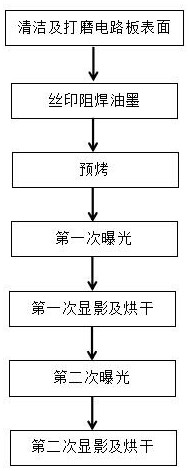

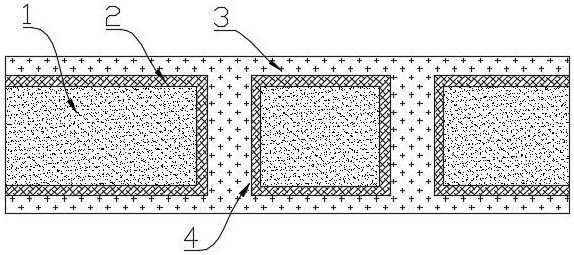

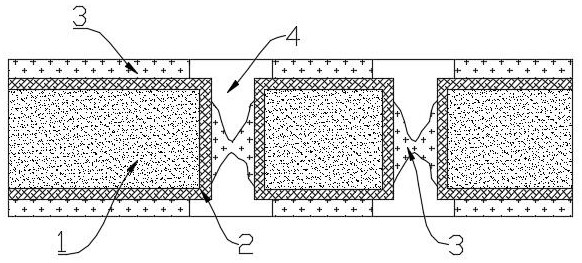

[0045] Such as figure 1 As shown, a method for eliminating the solder resist ink in the via hole of a printed circuit board, the method of the present invention is applicable to circuit boards whose via hole 4 has an aperture diameter of 0.2mm to 0.5mm, such as 0.2mm, 0.25mm, 0.3 mm, 0.35mm, 0.45mm, 0.5mm are all available.

[0046] This embodiment takes a double-sided circuit board as an example, and the method includes the following steps:

[0047] S1: clean the substrate 1 and the conductive copper layer 2 on the surface of the substrate 1, roughen the surface of the conductive copper layer 2 with a polishing device 10, improve the bonding of the solder resist ink, and clean the substrate 1 and the conductive copper layer 2 again, The two cleanings are carried out by water washing or ultrasonic to remove dust and impurities on the surface of the circuit board.

[0048] S2: silk screen printing, on the conductive copper layer 2, print the ink layer 3 of the predetermined co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com