Optical fiber and optical waveguide coupling method and structure and wafer testing method

An optical waveguide coupling and optical fiber technology, applied in the field of optical chips, can solve problems such as increasing the size of the device, and achieve the effects of improving the coupling efficiency and reducing the alignment accuracy and tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

[0028] It should be noted that the steps shown in the flowcharts of the accompanying drawings may be performed in a computer system, such as a set of computer-executable instructions, and that although a logical order is shown in the flowcharts, in some cases, The steps shown or described may be performed in an order different than here.

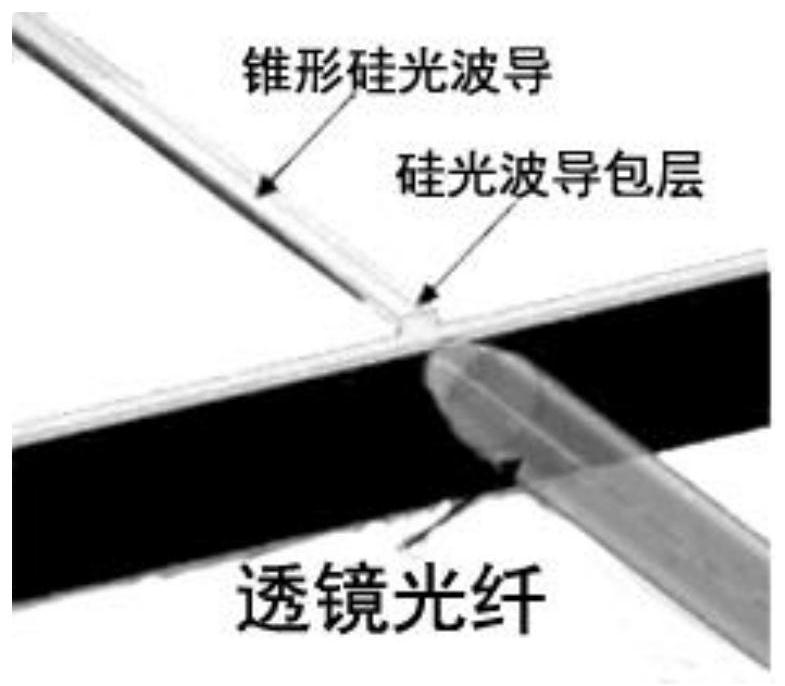

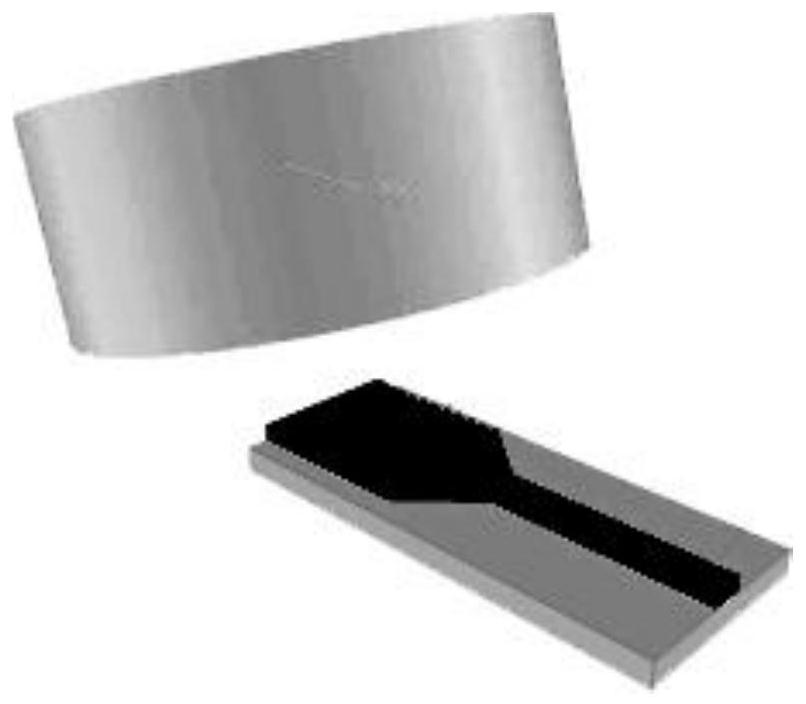

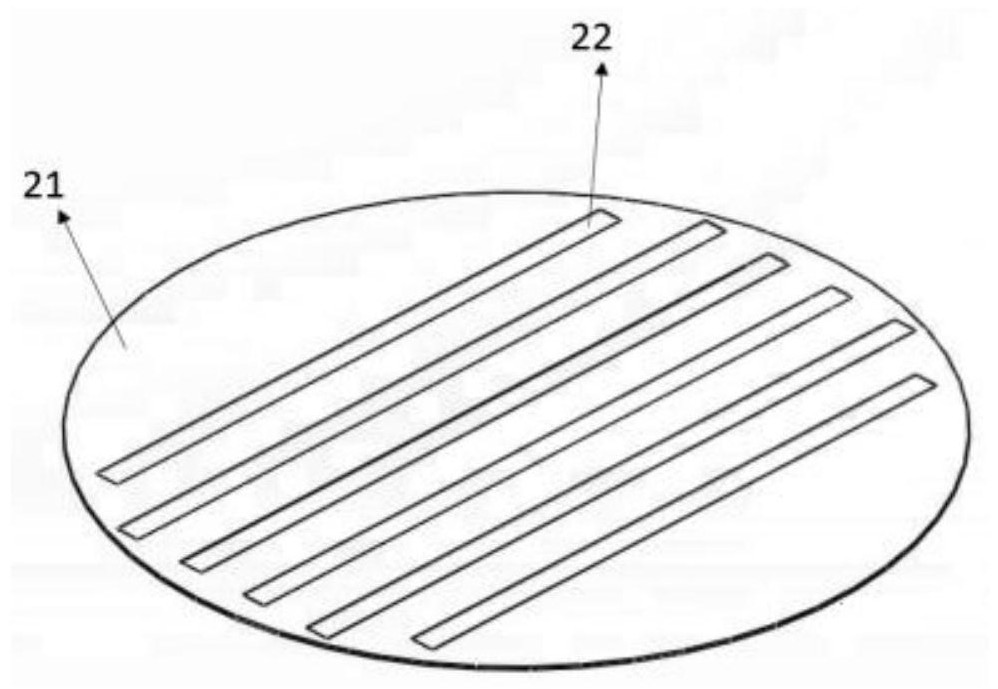

[0029] In this embodiment, the wafer-level packaging technology takes the wafer as the processing object, performs coupling packaging and testing on many chips on the wafer, and then cuts the wafer into single chips. High-throughput functional testing of silicon photonics is a key issue in large-scale chip manufacturing, and the most effective coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com