Double-sided PERC solar cell and preparation method thereof

A solar cell, double-sided technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increased production process, surface damage of silicon wafers, increased fragmentation rate, etc., to avoid mechanical damage and fragmentation rate, and simplify the production process. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

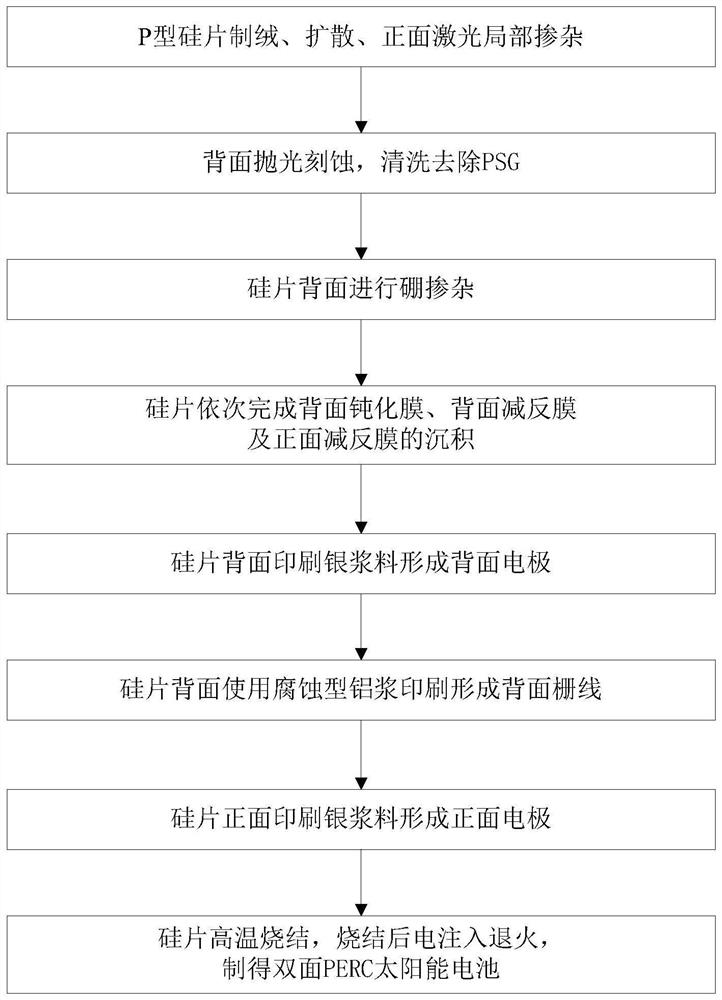

[0048] Such as figure 1 , the preparation method of a kind of double-sided PERC solar cell of the present embodiment, comprises the following steps:

[0049] (1) Take a P-type silicon wafer for texturing, diffuse the textured silicon wafer to form a PN junction on the front side, and then do laser doping on the front side to form a local heavily doped region N++;

[0050] (2) The silicon wafer is polished and etched on the back, the PN junction on the back and side is removed after diffusion, and the phosphosilicate glass PSG on the front is cleaned;

[0051] (3) Boron doping is performed on the back of the silicon wafer by ion implantation to form a doped region P+, where the boron doping concentration is 1×10 20 cm -3 ;

[0052] (4) Clean the silicon wafer, and complete the AlO on the back side in turn x Thin film, backside SiN x Thin film and front SiN x deposition of thin films in which AlO x The thickness of the film is 3nm;

[0053] (5) Print silver paste on the ba...

Embodiment 2

[0062] A kind of preparation method of double-sided PERC solar cell of the present embodiment, comprises the following steps:

[0063] (1) Take a P-type silicon wafer for texturing, diffuse the textured silicon wafer to form a PN junction on the front side, and then do laser doping on the front side to form a local heavily doped region N++;

[0064] (2) The silicon wafer is polished and etched on the back, the PN junction on the back and side is removed after diffusion, and the phosphosilicate glass PSG on the front is cleaned;

[0065] (3) Boron doping is carried out on the back of the silicon wafer by the amorphous silicon doping method to form a doped region P+, where the boron doping concentration is 8×10 19 cm -3 ;

[0066] (4) Clean the silicon wafer and complete the SiO on the back side in turn x Thin film, backside SiN x Thin film and front SiN x deposition of thin films in which SiO x The thickness of the film is 60nm;

[0067] (5) Print silver paste on the bac...

Embodiment 3

[0074] A kind of preparation method of double-sided PERC solar cell of the present embodiment, comprises the following steps:

[0075] (1) Take a P-type silicon wafer for texturing, diffuse the textured silicon wafer to form a PN junction on the front side, and then do laser doping on the front side to form a local heavily doped region N++;

[0076] (2) The silicon wafer is polished and etched on the back, the PN junction on the back and side is removed after diffusion, and the phosphosilicate glass PSG on the front is cleaned;

[0077] (3) Boron doping is performed on the back of the silicon wafer by high-temperature diffusion method to form a doped region P+, where the boron doping concentration is 5×10 18 cm -3 ;

[0078] (4) Clean the silicon wafer, and complete the AlO on the back side in turn x Thin film, backside SiN x Thin film and front SiN x deposition of thin films in which AlO x The thickness of the film is 5nm;

[0079] (5) Print silver paste on the back of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com