Heat radiating module and fan thereof

A cooling module and fan technology, which is applied in cooling/ventilation/heating transformation, instrument cooling, and instrumentation, etc., can solve problems such as lower reliability and pass rate, higher cooling module cost, and increased number of assembly and manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

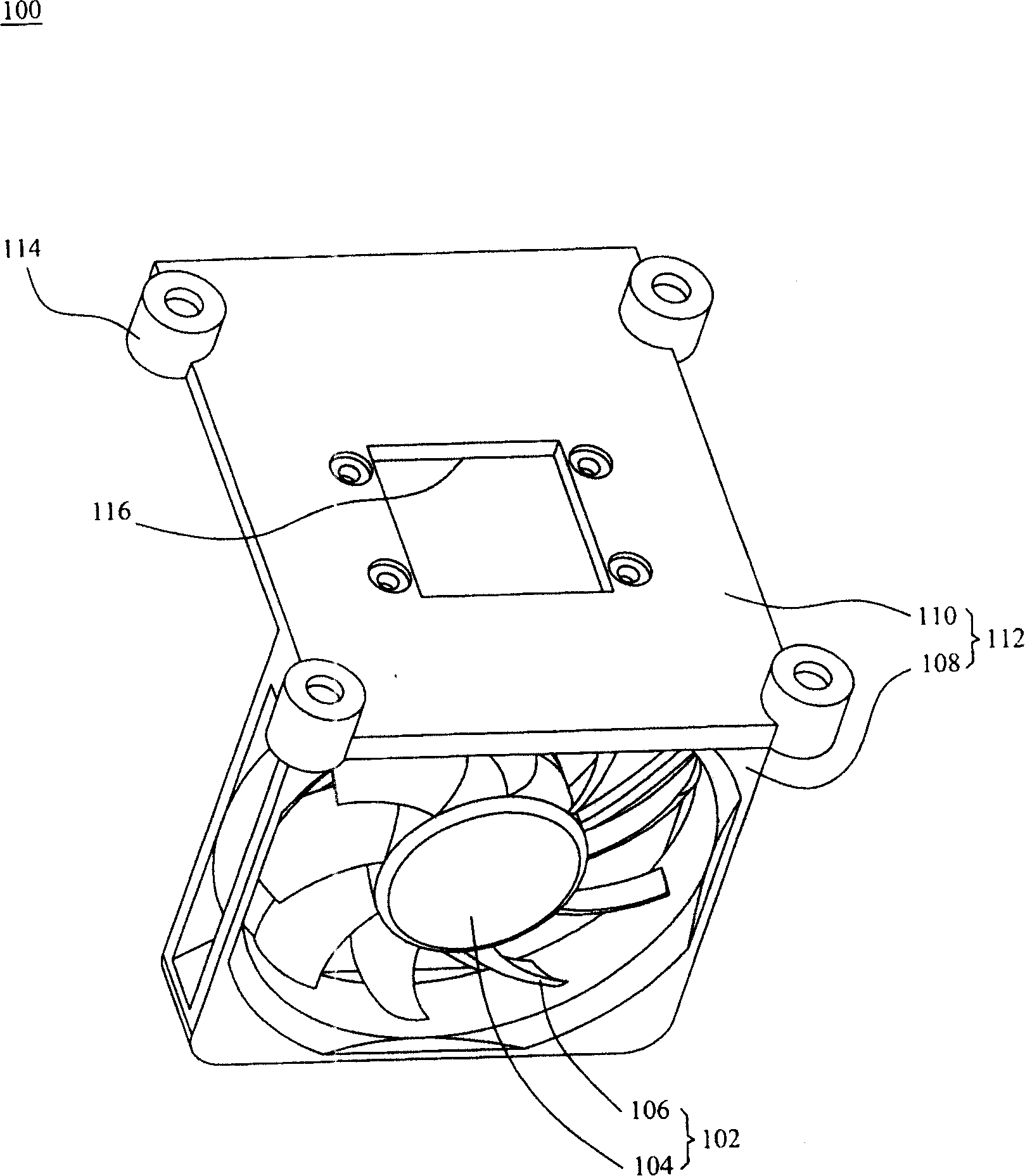

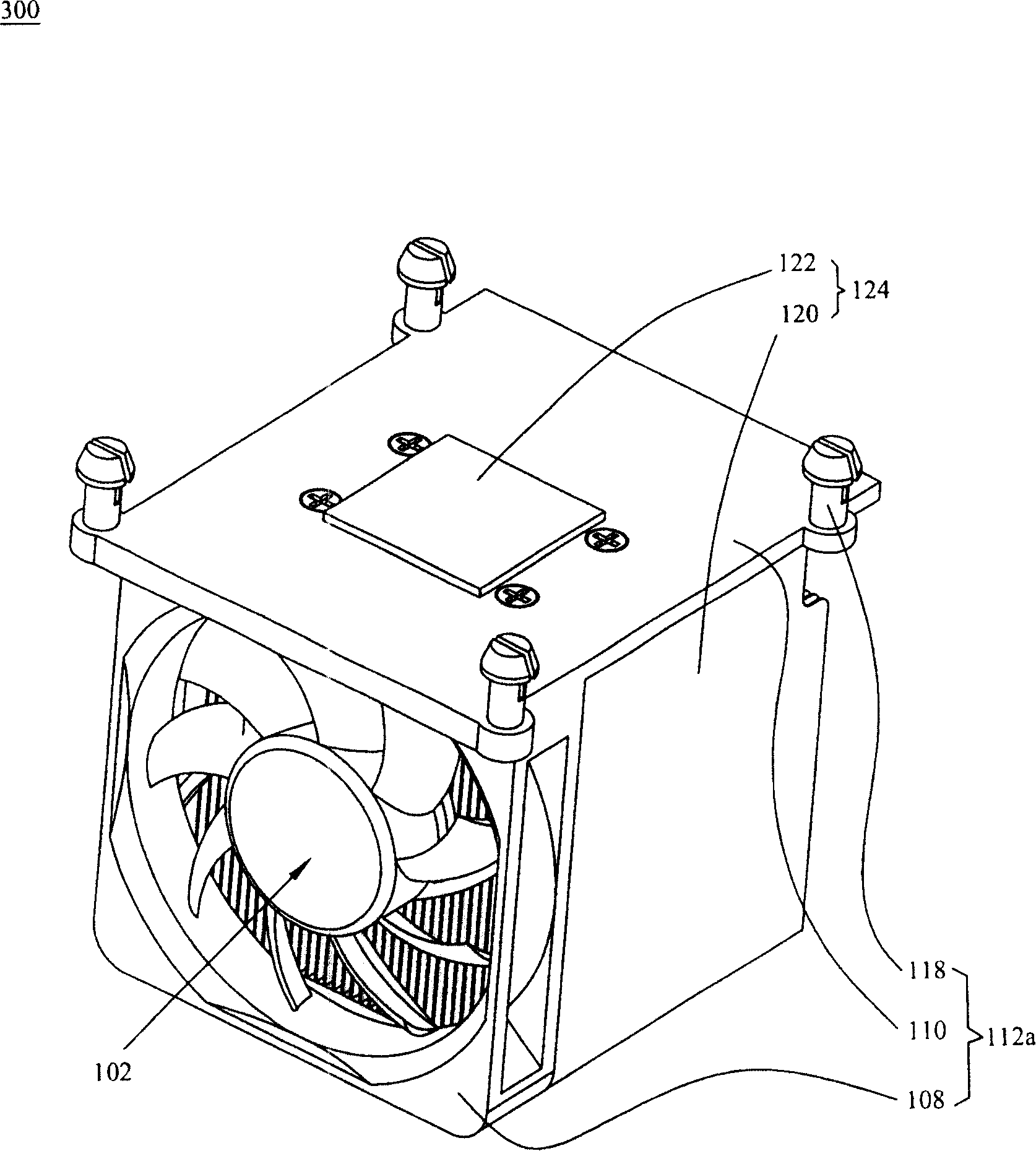

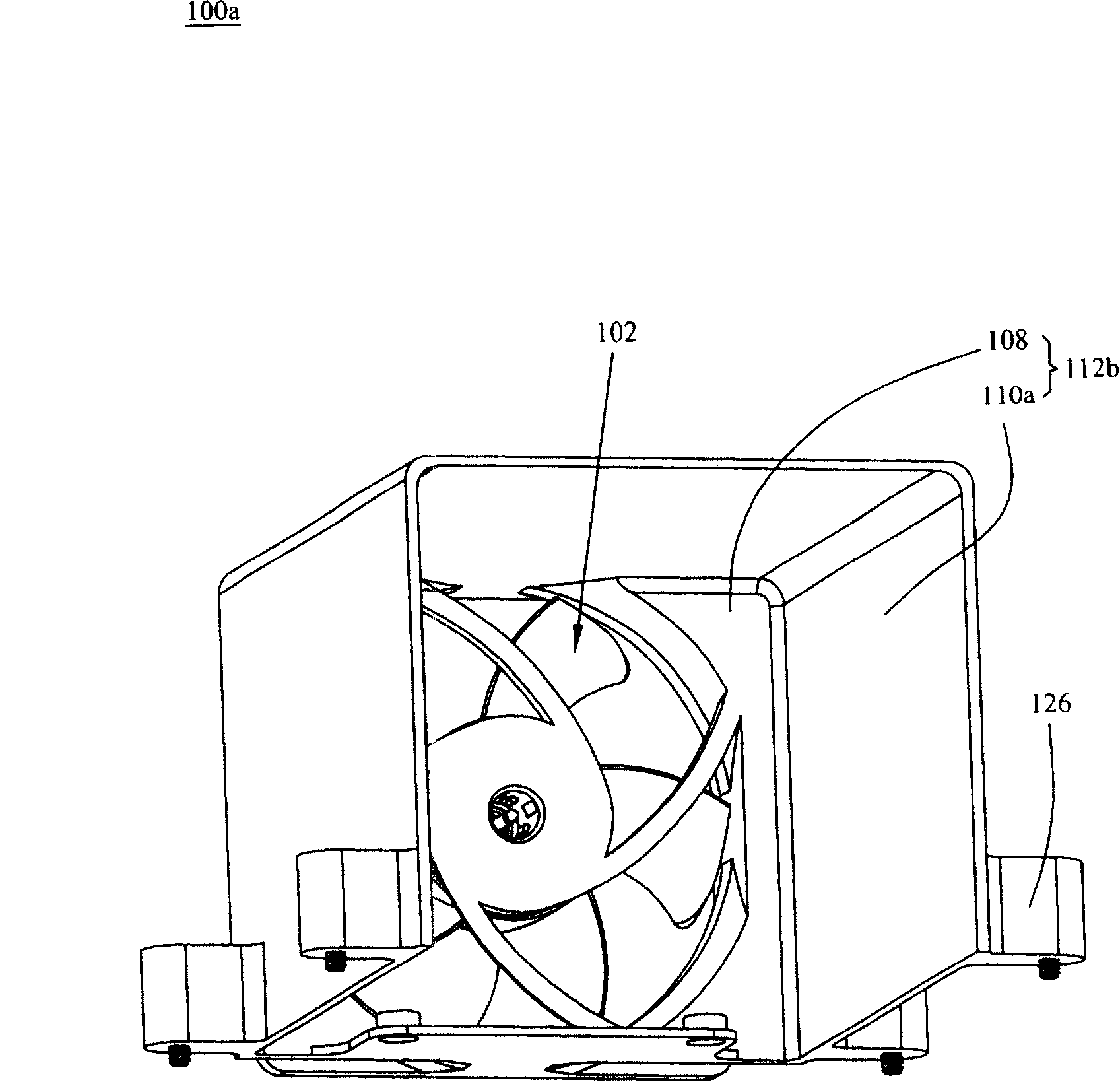

[0037] figure 1 It is a schematic diagram of the fan 100 according to the first preferred embodiment of the present invention. Please refer to figure 1 , the fan 100 has a fan frame 112 and an impeller 102 . The fan frame 112 has a body 108 and at least one extension 110, wherein the extension 110 protrudes from at least one side of the body 108, more specifically, the extension 110 axially protrudes from at least one side of the body 108 .

[0038] The extension part 110 and / or the main body 108 are used to connect with the circuit board 208 described later, and the main body 108 and the extension part 110 are integrally formed. Also, the fan frame is made of non-metallic material, wherein the non-metallic material is plastic, rubber or polymer material.

[0039] The main body 108 can be ring-shaped, and the cross-sectional shape of the extension part 110 in the axial direction of the main body 108 can be columnar, plate-shaped, L-shaped, U-shaped, O-shaped or D-shaped. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com