Off-axis signal processing method

A signal processing, off-axis technology, applied in optics, instruments, photolithography process of pattern surface, etc., can solve the problems of large amount of calculation, reduced productivity, and more time-consuming, so as to reduce alignment accuracy and improve productivity. rate, the effect of reducing computation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

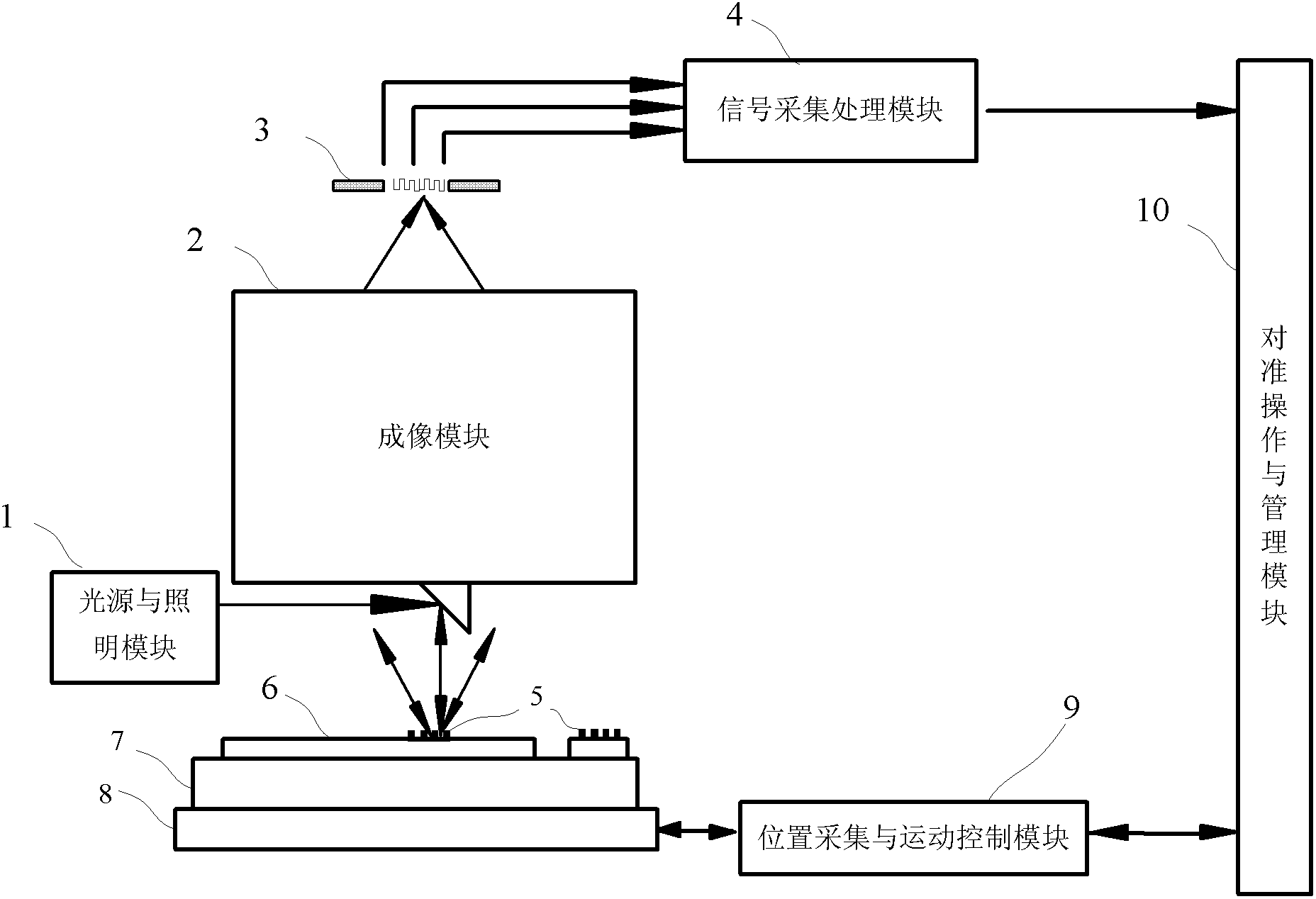

[0023] figure 1 is a schematic diagram of an off-axis alignment system according to a preferred embodiment of the present invention. Please refer to figure 1 . In this embodiment, the off-axis alignment system includes a light source and lighting module 1, an imaging module 2, a reference grating 3, a signal acquisition and processing module 4, an alignment mark 5, a workpiece table 7, a motion table 8, position acquisition and motion control module 9 and alignment operation and management module 10 . The workpiece table 7 carries the silicon wafer 6 .

[0024] In this embodiment, the light source and the illumination module 1 provide illumination light beams to irradiate the alignment marks 5 to form diffracted light carrying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com