Mask strip connection method and device as well as mask plate

A bonding method and bonding device technology, which are applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of low alignment accuracy and long time consumption, and achieve the goal of improving production efficiency and reducing alignment time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

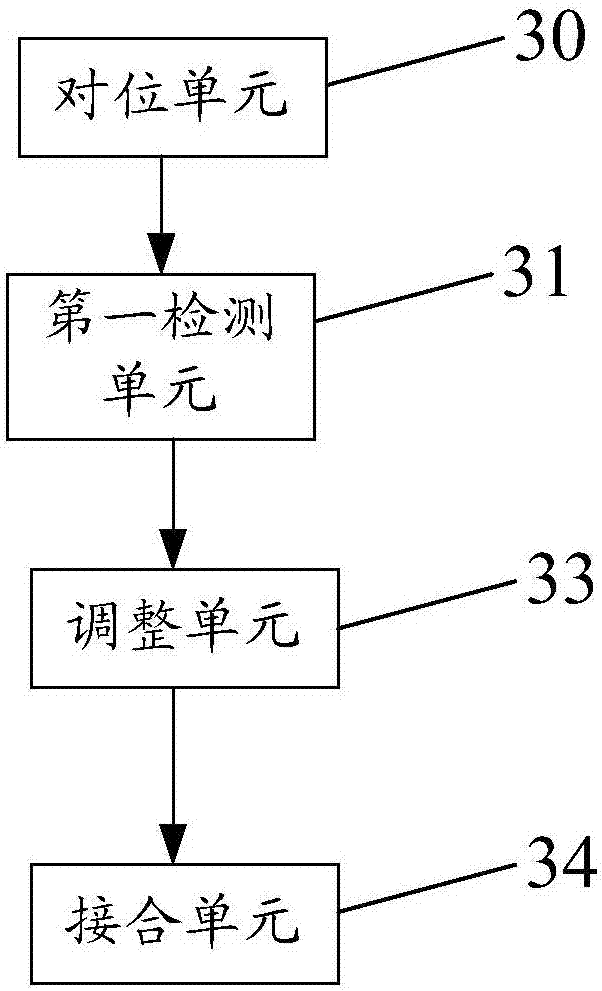

[0035] This embodiment provides a bonding device for mask strips, such as figure 2 As shown, it includes an alignment unit 30, a first detection unit 31, an adjustment unit 33 and a joint unit 34; wherein, the alignment unit 30 is used to align the frame of the mask strip at this stage; the first detection unit 31 is connected with the The alignment unit is connected to detect the position deviation of the frame after the alignment to obtain the first compensation data; the adjustment unit 33 is connected to the first detection unit and is used to adjust the position of the mask strip of this stage according to the first compensation data. Pixel coordinate reference; the bonding unit 34 is used to fix the mask strip of the current stage to the frame.

[0036] In the mask strip bonding device of this embodiment, the first detection unit 31 connected to the alignment unit 30 acquires the positional deviation of the frame after alignment as the first compensation data, and the a...

Embodiment 2

[0042] This embodiment provides a method for bonding mask strips, such as Figure 4 shown, including the following steps:

[0043] S1. Align the frame of the mask strip at the current level, and detect the position deviation of the frame after alignment to obtain the first compensation data;

[0044] S2. Adjust the pixel coordinate reference of the mask strip at the current level according to the first compensation data;

[0045] S3. Fix the mask strip of the current stage to the frame according to the pixel coordinate reference.

[0046] In the bonding method of the mask bar in this embodiment, the position deviation of the frame after alignment is used as the first compensation data to compensate to the pixel coordinate reference, so the difference between the actual position of the mask bar frame and the target position can be set ± a μm For a larger range, this can make the mask strip frame of this level fall into the threshold range of alignment accuracy in a short peri...

Embodiment 3

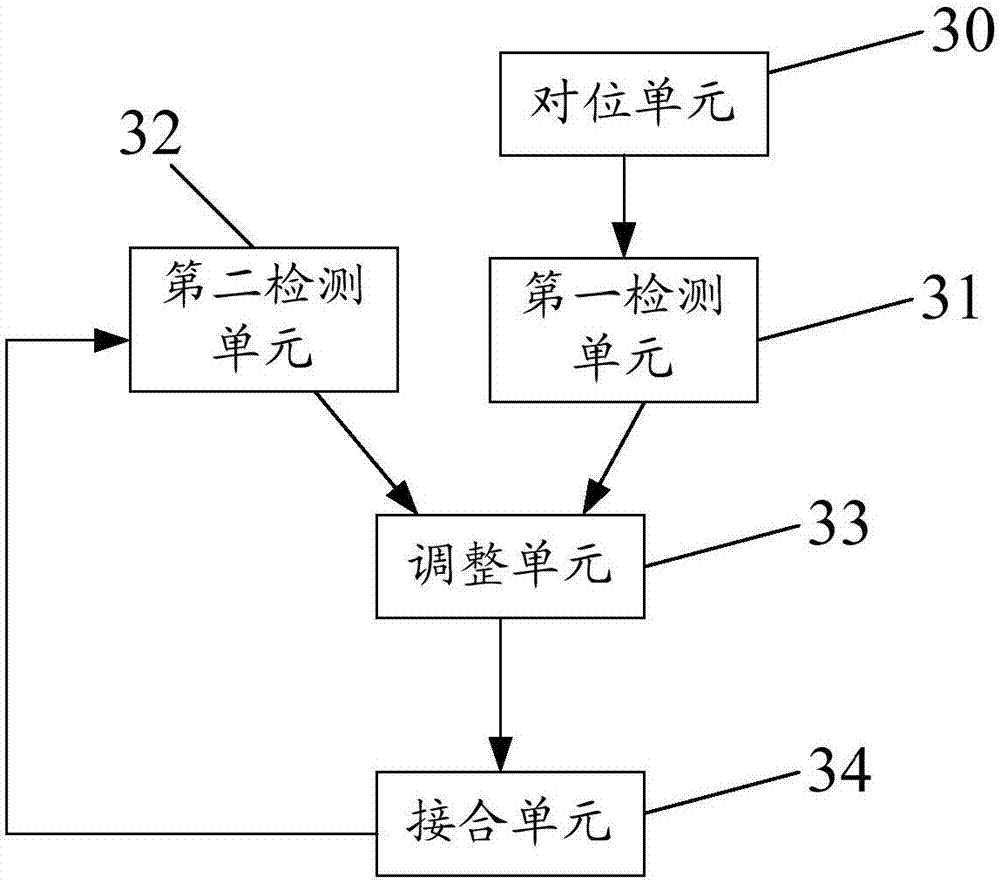

[0048] This embodiment provides a method for bonding mask strips, which is combined by using the bonding device for mask strips in Embodiment 1, such as Figure 5 As shown, it specifically includes the following steps:

[0049]S01a, the alignment unit 30 aligns the frame of the mask strip at the current stage, and the first detection unit 31 detects the position deviation of the frame after alignment to obtain first compensation data.

[0050] S01b, the second detection unit 32 obtains the second compensation data of the mask bar frame of the current stage according to the average value of the pixel position deviation of the fixed mask bar.

[0051] S02. The adjustment unit 33 adjusts the pixel coordinate reference of the mask strip at the current stage according to the first compensation data and the second compensation data.

[0052] S03. The joining unit 34 fixes the mask strip of the current stage to the frame according to the pixel coordinate reference.

[0053] That is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com