FSAE racing car semiaxis length determination and bounce checking method

A shaft length and maximum length technology, which is applied in the field of determining the length of the long half shaft of FSAE racing cars and checking the runout, can solve the problems of top dead, falling off of the moving joint, lack of checking the length and angle of the driving half shaft, etc., to ensure safety , Improving the service life, the effect of simple calculation and calibration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

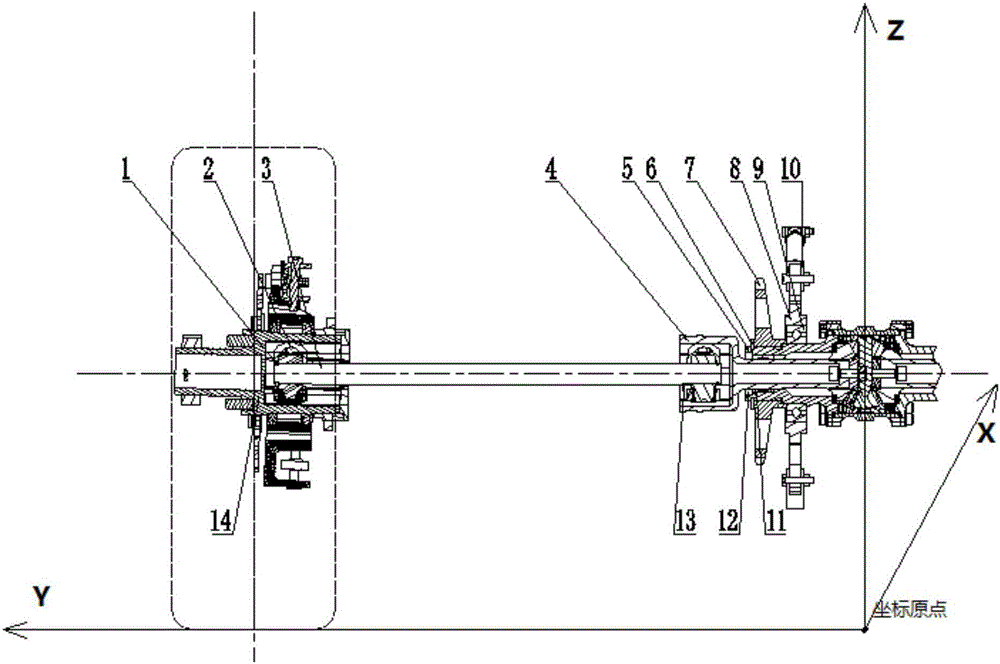

[0063] Embodiment 1: Determination of semi-axis length

[0064] Take the oil truck design of Chang'an University's 2015 Hunting Team as an example:

[0065] 1. Known data

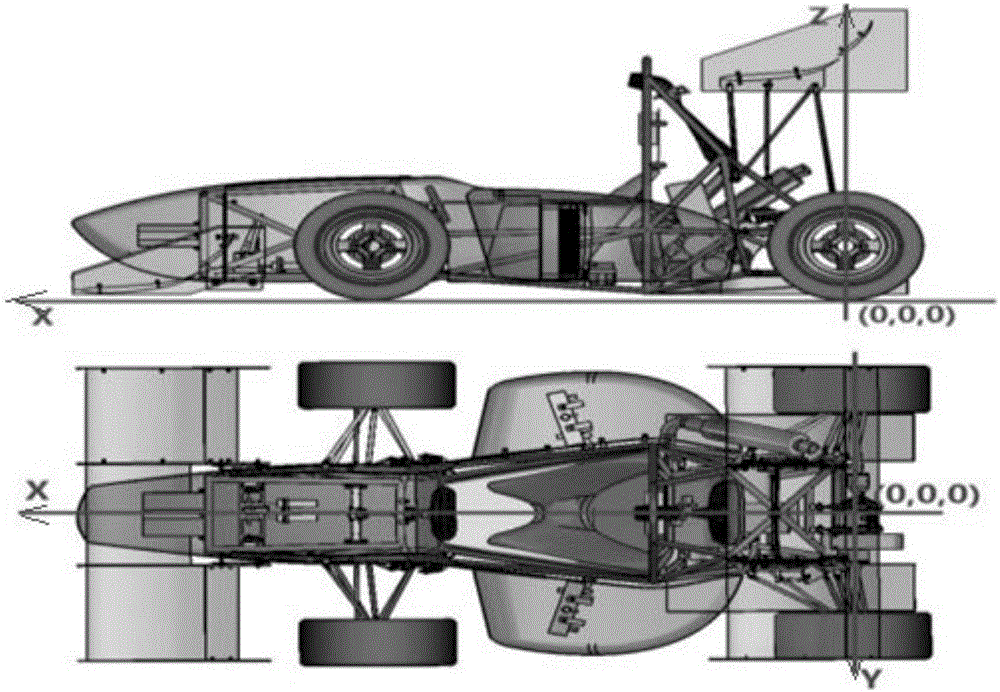

[0066] The three-dimensional coordinates of the whole vehicle during the design process of the 2015 Chang’an University’s 2015 Leafer Racing Team are as follows:

[0067] Coordinate origin: the intersection of the vertical projection line of the rear axle on the ground and the longitudinal center plane of the racing car; X-axis: a straight line parallel to the horizontal plane passing through the origin on the longitudinal center plane of the racing car, and the positive direction is from the rear axle to the front axle; Y Axis: the vertical line of the longitudinal center plane of the racing car passing through the origin, with the driver as a reference, the positive direction is from right to left; Z axis: a straight line passing through the origin and perpendicular to the horizontal plane, the positive ...

Embodiment 2

[0085] Embodiment 2: Calibration of half axis

[0086] The method for determining the half shaft length of the FSAE racing car is the same as in embodiment 1, the difference is that the verification process of the half shaft is as follows:

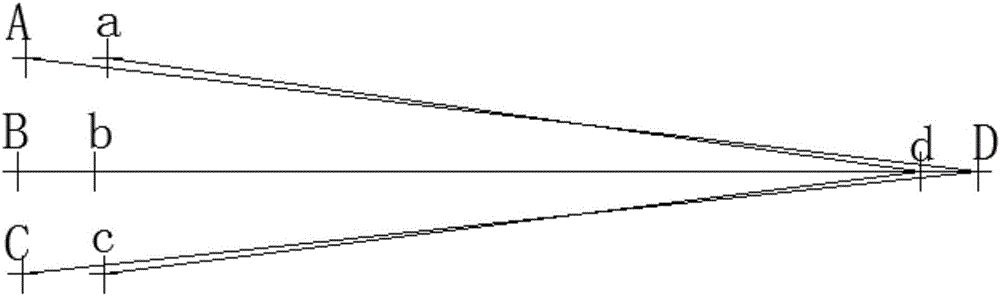

[0087] The three-pin shafts used in the outer and inner ball cages are the three-pin shafts of Alto’s inner ball cage, and the raceway dimensions are the same. Since the raceway depth (70mm) on the hub side is relatively deep, the inner ball cage side The depth of the raceway (50mm) is relatively shallow. Since the three-pin shafts at both ends move in the two raceways when the half-shaft is beating with the wheel, so to calculate the maximum half-shaft inclination angle allowed by the three-pin shaft channel, use the outer ball The cage raceway is used for calculation; the diameter of the long semi-axis is 21mm, the minimum diameter of the three-pin raceway is 40mm, and the depth of the raceway is 70mm. Draw a sketch on CATIA as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com