Method for controlling an actuating assembly for a clutch, an actuating assembly, and a drive assembly having an actuating assembly of this type

A technology for clutches and moving mechanisms, applied in clutches, electric clutches, mechanically driven clutches, etc., can solve problems such as switching inaccuracy, and achieve the effects of avoiding friction, prolonging functional capacity and life, and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

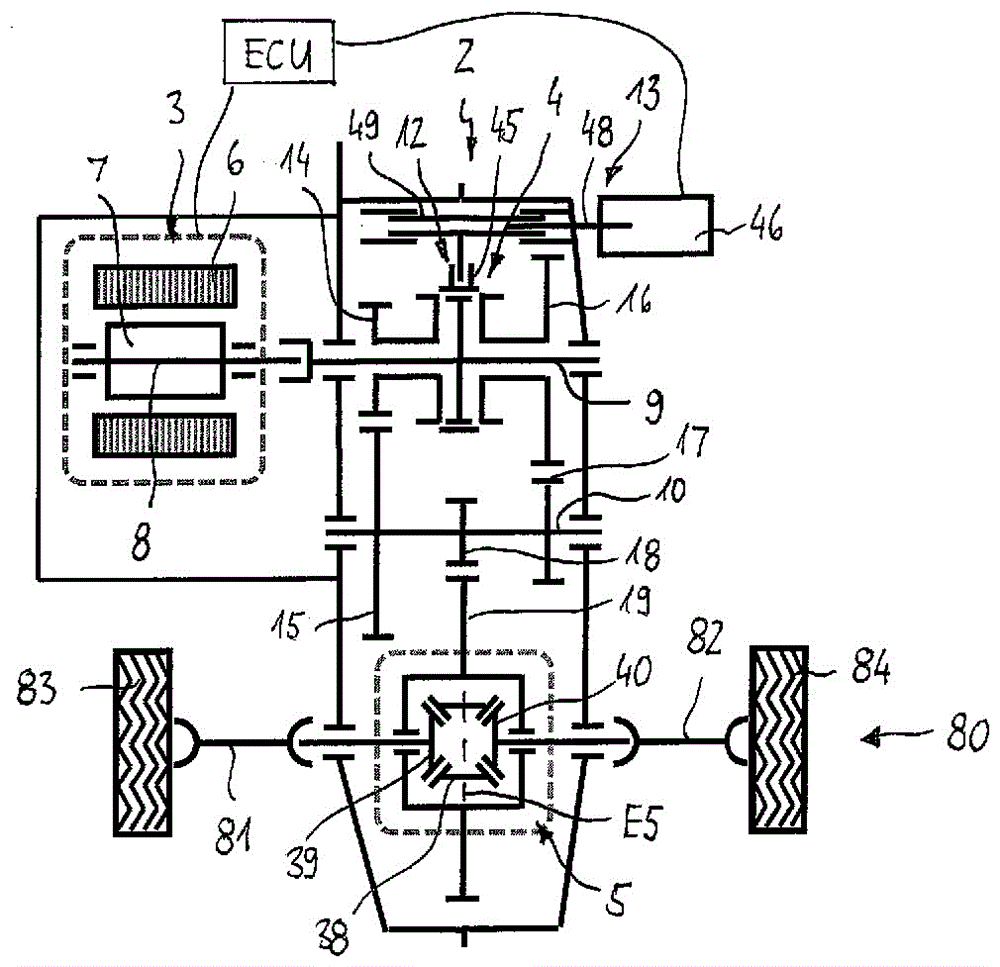

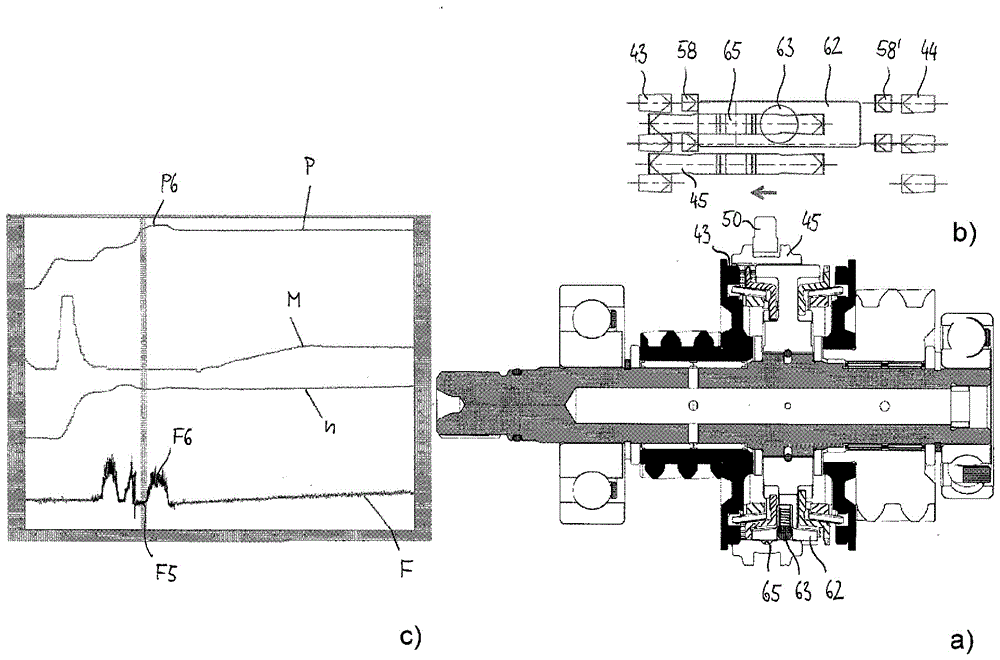

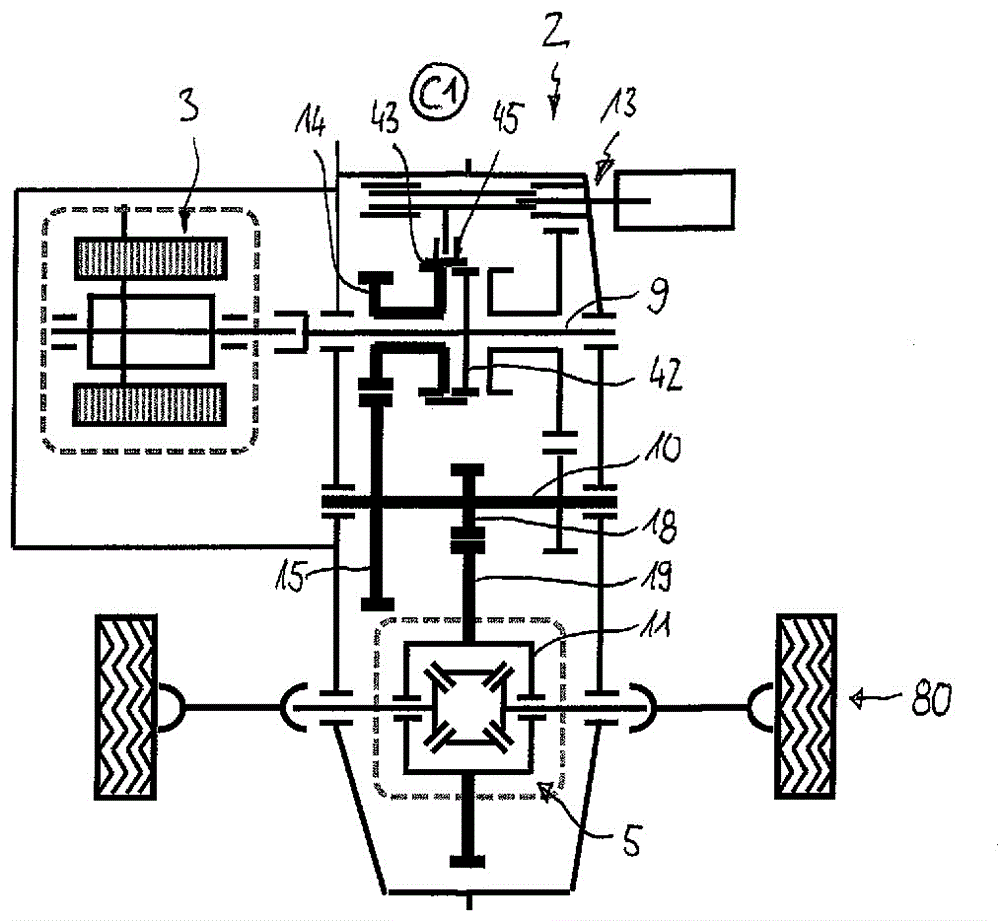

[0058] Figures 1 to 7 are described together below. figure 1 An actuation mechanism 1 according to the invention is shown as part of a drive mechanism 2 according to the invention. The driving mechanism 2 includes an electric motor 3 , a switching transmission mechanism 4 and a differential transmission mechanism 5 . The electric motor 3 , the switching gear 4 and the differential gear 5 together form an electric drive for driving a drive shaft of the motor vehicle. In this case, the electric drive can be used as the sole drive source or together with an additional drive source.

[0059] The electric motor 3 comprises a stator 6 and a rotor 7 , rotatable relative to the stator, which rotationally drives a motor shaft 8 when the electric motor is energized. The rotational movement of the motor shaft 8 is transmitted to the drive shaft 9 of the switching gear 4 . The electric motor 3 is supplied with current from a battery, wherein the battery can also be charged by the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com