Fruit and vegetable picking grabber

A grabber, fruit and vegetable technology, applied in the field of machinery, can solve the problems of inability to pick continuously, unfavorable storage on the surface of the fruit, the accuracy of grabbing, and the inability to cope with the picking of growth density peels, so as to achieve low cost, increase picking speed, and control difficulty low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below with reference to accompanying drawing, the concrete implementation of the work of the present invention is described in further detail.

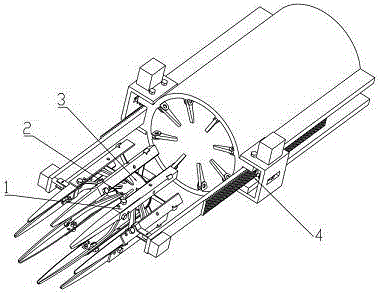

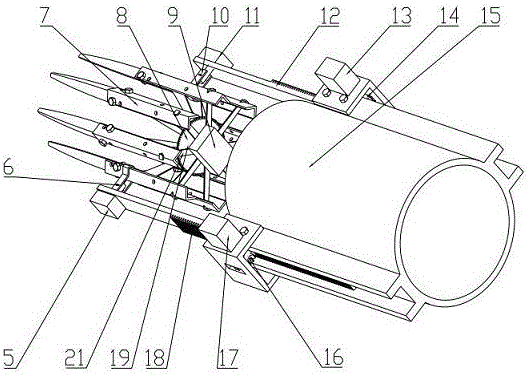

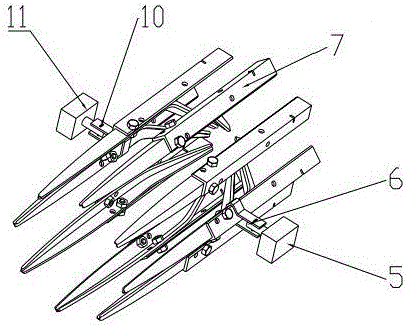

[0017] Such as figure 1 As shown, grabbing system (1), cutting system (2), sensing system (3), and propulsion system (4). The motor (13) and the motor (17) respectively drive the gear (14) and the gear (16) to drive the rack (12) and the rack (18) to move away from the sleeve (15), thereby driving the gripping system (1 ) to move forward to the fruits and vegetables. When the grabbing system (1) advances to the fruits and vegetables and catches them outside the fruits and vegetables, the motor (5) and the motor (11) drive the gripper (7) to rotate by driving the rotating shaft (6) and the rotating shaft (10) respectively , the branch will enter the cutting system (3) behind the gripper along the gap between each gripper segment, and the propulsion system (4) starts to work at this time to retract the gripping system (1), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com