Panel component movement mechanism and microwave steaming and baking integral machine

A motion mechanism and panel assembly technology, applied in microwave heating, electrical components, steam cooking utensils, etc., can solve the problem of the panel body being fixed, and achieve the effect of improving space utilization, strong overall sense, and increasing use capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

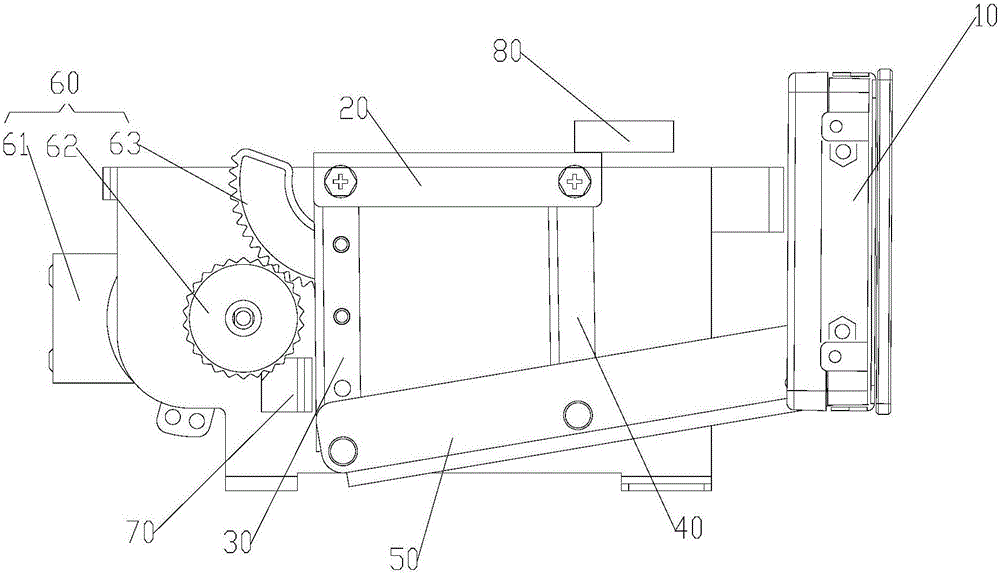

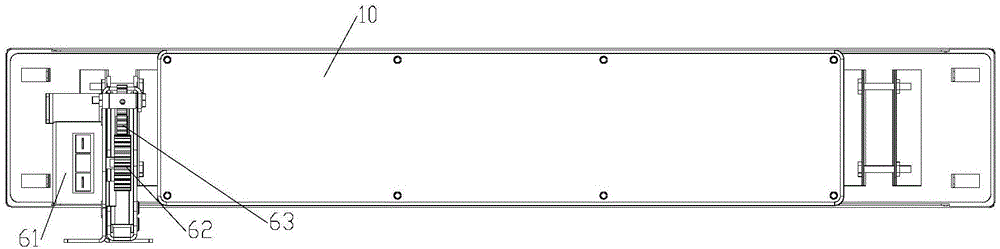

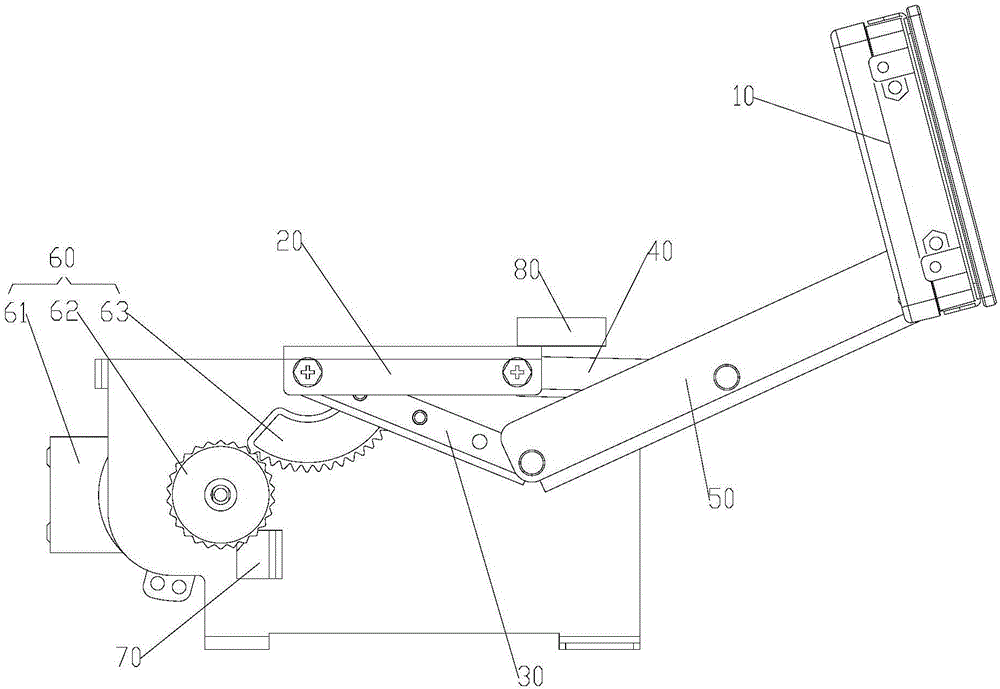

[0033] Such as Figure 1 to Figure 4 As shown, the panel assembly kinematic mechanism panel body 10, the mounting frame 20 arranged at the position to be installed, the first connecting rod 30, the second connecting rod 40 arranged at intervals from the first connecting rod 30, the third connecting rod 50 and the drive Part 60, the first end of the first connecting rod 30 is hinged with the mounting frame 20; the first end of the second connecting rod 40 is hinged with the mounting frame 20; the first end of the third connecting rod 50 is hinged with the first end of the first connecting rod 30 The two ends are hinged, the second end of the second connecting rod 40 is hinged with the middle part of the third connecting rod 50, the panel body 10 is fixed on the second end of the third connecting rod 50; the driving part 60 is arranged on the mounting frame 20, and drives The portion 60 is connected with the first connecting rod 30 , the second connecting rod 40 or the third con...

Embodiment 2

[0045] The structure and principle of the second embodiment are basically the same as that of the first embodiment, the only difference between the two is that the driving part includes a motor, a first gear and a second gear meshed with the first gear, and the first gear is installed on the output shaft of the motor ; The second gear is fixed on the first connecting rod, the second connecting rod or the third connecting rod. Considering the space installation problem, the second gear is fixed on the first connecting rod.

Embodiment 3

[0047] The structure and principle of the third embodiment are basically the same as that of the first embodiment, the only difference between the two is that the driving part includes a motor, a first arc-shaped rack and a second arc-shaped rack meshing with the first arc-shaped rack, and the motor A first arc-shaped rack is installed on the output shaft; the second arc-shaped rack is fixed on the first connecting rod, the second connecting rod or the third connecting rod. Considering the problem of space installation, the second arc rack is fixed on the first connecting rod.

[0048] The movement mechanism of the panel assembly with the above structure can effectively solve the problem that the three-in-one micro-steaming and grilling product takes up a lot of space when the water tank is placed on one side of the whole machine. By setting the moving mechanism of the panel assembly in the form of a four-bar mechanism, the display screen is fixed on the third connecting rod s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com